In an increasingly complex industrial context, the transition to a Model-Based Enterprise (MBE) is becoming a strategic priority. MBE relies on the use of 3D models enriched with data throughout the product lifecycle. 3DViewStation stands out as a key tool to support this transformation, offering visualization, collaboration, and integration features tailored to MBE requirements.

3DViewStation: A Key Tool for a Successful MBE Transition

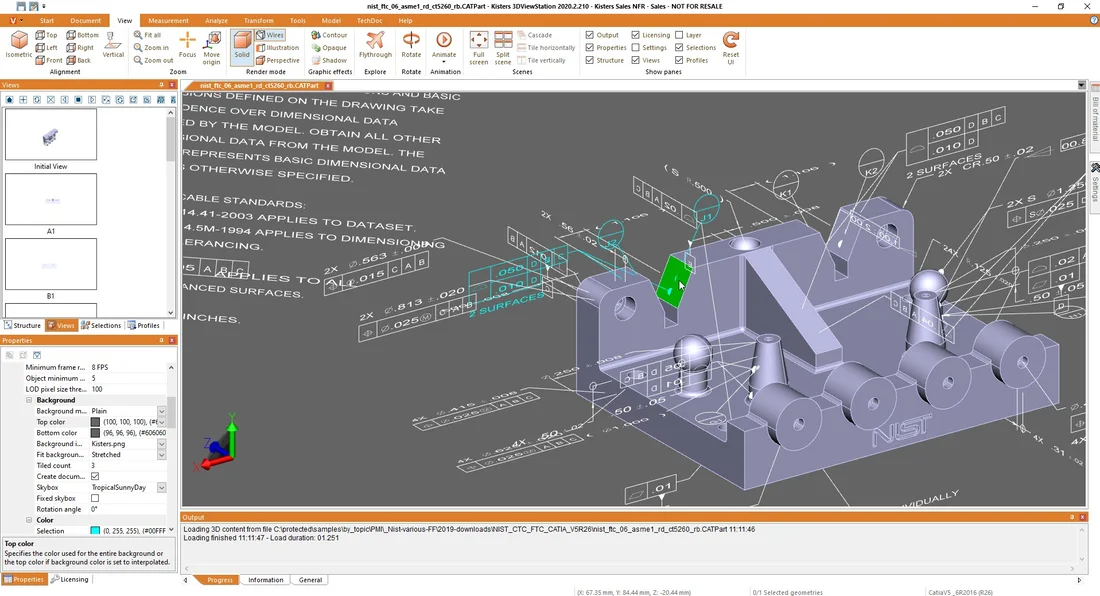

3DViewStation is a recognized 3D visualization solution known for its performance and versatility. It allows not only the visualization of complex 3D models but also the integration of Product Manufacturing Information (PMI), essential for efficient production. This ability to centralize and visualize all critical data in a single model is at the core of the MBE philosophy, which seeks to eliminate barriers between the various stages of design, engineering, and production.

The Role of 3DViewStation in the MBE Ecosystem

One of the major strengths of 3DViewStation lies in its seamless integration with Product Lifecycle Management (PLM) systems. This integration enables smooth processes where each stakeholder can access the necessary information at every stage of product development without handling multiple documents or formats. By simplifying data access, 3DViewStation significantly reduces errors and inefficiencies while improving collaboration across teams.

ASML: A Success Story with 3DViewStation

To illustrate the impact of 3DViewStation in an MBE approach, the case of ASML is particularly relevant. ASML, a world leader in lithography equipment for the semiconductor industry, embarked on a Model-Based Definition (MBD) and PMI initiative to improve its design and manufacturing processes. In this context, ASML chose to integrate 3DViewStation into its workflow.

Before adopting 3DViewStation, ASML faced significant challenges related to the visualization and management of PMI data. Teams often had to navigate between multiple systems and formats to access the necessary data, leading to inefficiencies and risks of error. By adopting 3DViewStation, ASML was able to centralize the visualization of PMI data within its 3D models, allowing engineers and technicians to easily access all critical information from a single, intuitive interface.

At ASML, the adoption of 3DViewStation led to a significant reduction in PMI-related errors and an improvement in production times thanks to the centralization of data in a single, interactive environment.

The impact of KISTERS 3DViewStation on ASML's operations was highlighted by Helmar Kraus, Supplier Quality Engineer at ASML, in a video where he explains how this tool improved communication, reduced production cycles, and efficiently managed complex 3D models. This testimony highlights ASML's operational efficiency and innovation capabilities enhanced by 3DViewStation. You can watch the full testimony here: Helmar Kraus Testimonial - ASML.

PMI Integration with 3DViewStation: A Crucial Value Add

Integrating PMI data into 3D models is another fundamental aspect of 3DViewStation's success in an MBE environment. PMI includes critical data such as dimensional tolerances, geometric annotations, and manufacturing instructions, which are essential to ensure parts are produced according to design specifications.

With 3DViewStation, users can not only visualize this information but also interact with it dynamically. For example, a technician can select geometry to immediately see the associated tolerances or specific manufacturing requirements, all without leaving the 3D visualization environment. This interactivity reduces the risk of errors since all necessary information is accessible in one place and always synchronized with the 3D model.

Tangible Benefits of 3DViewStation for a Model-Based Enterprise

The adoption of an MBE approach with tools like 3DViewStation brings several concrete benefits to companies. First, communication between different stakeholders improves significantly. When all critical information is integrated into a single 3D model, engineers, designers, technicians, and project managers can collaborate more effectively, avoiding misunderstandings often caused by using different data formats.

Furthermore, reducing cycle times is another major advantage. With 3DViewStation, companies can accelerate the product development process by eliminating redundant steps and minimizing the risk of errors. Integrated PMI data ensures that each production stage is executed according to specifications, reducing the need for rework or changes afterward.

Finally, the ability to handle large datasets without performance loss is essential for companies dealing with complex models. 3DViewStation is designed to manipulate large 3D files with remarkable fluidity, allowing companies to work with detailed models without compromising efficiency or responsiveness.

Conclusion: A Successful Digital Transformation with 3DViewStation

The transition to a Model-Based Enterprise is a challenge for many organizations, but with tools like 3DViewStation, this challenge becomes an opportunity for continuous improvement. By centralizing critical information within 3D models and integrating these models into company processes, 3DViewStation not only facilitates collaboration and communication but also fosters innovation and production quality. ASML's example clearly demonstrates the tangible benefits this solution can bring, enabling the company to remain competitive in a highly technological and demanding sector.

By integrating PMI data into an MBE environment, 3DViewStation establishes itself as an indispensable tool for companies looking to optimize their processes and gain agility in an increasingly digitized world.