In industry, long-term archiving of CAD data represents a crucial strategic issue. Beyond simple preservation, model validation ensures their future usability in a context of constant technological evolution. Aerospace, automotive, and defense companies face major challenges: how to ensure that their digital models will remain usable and faithful to their design intent over decades?

The LOTAR (LOng Term Archiving and Retrieval) standard establishes a rigorous framework for this issue, but its implementation requires specific validation processes. Without precise data qualification, archived models risk becoming unusable or, worse, introducing errors when reused in the future.

Table of contents

- Fundamentals of long-term CAD data archiving

- Specific challenges of technical data archiving

- Validation methodologies for long-term archiving

- Neutral formats and validation properties

- CADIQ: Reference solution for CAD archive validation

- Practical applications and case studies

- Best practices and recommendations

Fundamentals of long-term CAD data archiving

Long-term archiving of CAD data is part of a global strategy for preserving a company's technical heritage. Unlike classical document archiving, the preservation of 3D models involves maintaining not only geometric data but also design intent and associated manufacturing information.

The LOTAR standard, developed jointly by European and American aerospace industries, defines the processes and methods to ensure access, understanding, and reuse of technical data over periods that can exceed 50 years. This standard is based on several international standards:

- ISO 14721 (OAIS - Open Archival Information System): reference model for archiving systems

- ISO 10303 (STEP): standard for product data exchange

- EN/NAS 9300: technical specifications for long-term archiving

The lifecycle of archived technical data comprises several distinct phases:

- Data preparation: selection and qualification of models to be archived

- Conversion: transformation to enduring neutral formats

- Validation: verification of integrity and compliance

- Storage: preservation in a secure system

- Preservation: maintenance and periodic migration

- Access: exploitation of archives as needed

The validation phase constitutes the critical step that guarantees the quality of archives and their future usability. Without this step, archiving becomes simple storage of potentially unusable data.

Specific challenges of technical data archiving

Long-term archiving of CAD data faces numerous technical and organizational obstacles that compromise the durability of information. These challenges require a methodical approach and specialized solutions.

Rapid evolution of formats and technologies

The CAD software landscape is constantly evolving, with update cycles that can make certain proprietary formats obsolete in just a few years. A model created 20 years ago may become unreadable by current versions of the same software. This technological obsolescence constitutes a major risk for industries whose products have lifecycles spanning several decades.

Preservation of design intent

Beyond simple geometry, CAD models contain design intent: constraints, parametric relationships, annotations, tolerances, and manufacturing information (PMI). These elements are often altered or lost during conversions between formats, thus compromising future understanding of the model.

Impact of quality defects

Geometric imperfections present in original models generally amplify during successive conversions. Common problems include:

- Degeneration of edges and faces

- Topological breaks and discontinuities

- Loss of precision in complex surfaces

- Inconsistencies in assemblies

- Alteration of annotations and PMI

These defects, sometimes initially imperceptible, can render the model unusable for certain future applications such as manufacturing or analysis.

Revision management and traceability

Technical models constantly evolve throughout their development cycle. Maintaining consistency between different archived versions and documenting the history of modifications represents a major organizational challenge, particularly in industries subject to strict regulatory requirements.

| Challenge | Impact on archiving | Recommended approach |

|---|---|---|

| Technological obsolescence | Loss of access to archived data | Conversion to standardized neutral formats |

| Loss of design intent | Misunderstanding of original constraints | Validation of semantic properties |

| Geometric degradation | Models unusable for manufacturing | Geometric qualification before archiving |

| PMI inconsistency | Loss of manufacturing information | Verification of annotations and tolerances |

Validation methodologies for long-term archiving

Effective validation of CAD data for long-term archiving relies on structured methodologies that guarantee the integrity and usability of models. These approaches combine quality control, equivalence verification, and documentation of essential properties.

Quality criteria for models intended for archiving

The qualification of CAD models revolves around several complementary dimensions:

- Geometric integrity: absence of degeneracies, surface continuity, dimensional accuracy

- Topological consistency: validity of relationships between geometric entities, absence of interferences

- Annotation compliance: consistency of PMI, readability of tolerances, adherence to standards

- Structural usability: logical organization of component trees, clear identification of parts

These criteria must be adapted to the specificities of each industry and applicable regulatory requirements. A compliance matrix allows formalizing acceptability thresholds for each type of potential defect.

Equivalence between native and derived models

Conversion to neutral formats inevitably introduces modifications in models. Verifying the equivalence between the source (native) model and the derived (neutral) model constitutes a fundamental step in the validation process. This verification is performed at several levels:

- Geometric equivalence: comparison of volumes, surfaces, and edges

- Topological equivalence: verification of relationships between entities

- Semantic equivalence: preservation of annotations and PMI

- Structural equivalence: conservation of assembly tree

The observed discrepancies must be evaluated according to their potential impact on future uses of the models. Some differences may be acceptable for documentary use but not for manufacturing.

Documentation of acceptable defects

Absolute perfection of models is rarely achievable, particularly for complex geometries. A pragmatic approach consists of precisely documenting residual defects and evaluating their impact on intended uses:

- Classification of defects by type and severity

- Evaluation of potential consequences

- Justification of exceptions to standard criteria

- Identification of future usage limitations

This documentation becomes an integral part of the metadata associated with the archive, providing essential context for future users.

Neutral formats and validation properties

The use of standardized neutral formats constitutes the cornerstone of any long-term archiving strategy. These formats, independent of proprietary CAD systems, offer better guarantees of durability and interoperability.

Role of neutral formats in archiving

The neutral formats most commonly used for long-term archiving include:

- STEP (ISO 10303): international standard for product data exchange, particularly the application protocols AP203, AP214, and AP242 that support PMI

- JT (ISO 14306): lightweight format oriented toward visualization but also supporting exact geometry and PMI

- 3D PDF: visualization format based on PRC or U3D, suitable for documentation but limited for technical applications

The STEP AP242 format has established itself as a reference for long-term archiving of CAD data due to its ability to represent not only precise geometry but also annotations, tolerances, and validation properties.

Validation properties in STEP files

Validation properties constitute an essential mechanism for verifying the integrity of models after conversion. These properties, calculated on the native model and then included in the STEP file, allow confirming that critical information has been correctly preserved.

The main categories of validation properties include:

- Geometric properties: volume, surface area, center of gravity, moments of inertia

- Point sampling: reference points on surfaces for later verification

- Assembly properties: number of components, hierarchy, relative positions

- Annotation properties: number and types of annotations, affected areas, references

Point clouds and geometric validation

Sampling points on surfaces (point clouds) constitutes a particularly effective method for validating geometric fidelity. This approach consists of:

- Generating a set of points on the surfaces of the native model

- Including these points in the STEP file as validation properties

- During future verification, confirming that these points still belong to the surfaces

The observed discrepancies reveal potential deformations of the geometry, allowing precise identification of problematic areas. This method is particularly relevant for complex surfaces and functionally critical areas.

| Property type | Information validated | Typical application |

|---|---|---|

| Mass properties | Volume, surface area, centroid | Global integrity verification |

| Point clouds | Precise geometry of surfaces | Validation of functional areas |

| Assembly properties | Structure and relative positions | Verification of mechanisms |

| Annotation properties | PMI and tolerances | Compliance with manufacturing requirements |

CADIQ: Reference solution for CAD archive validation

In the demanding context of long-term archiving, CADIQ establishes itself as a specialized solution for the qualification and validation of CAD models. Its advanced functionalities precisely address the challenges of preserving technical data.

Key functionalities for archive validation

CADIQ offers a systematic approach for validating models intended for long-term archiving:

- Comprehensive analysis of CAD models: thorough verification of geometry, features, and PMI to identify potentially problematic defects

- Independent validation: impartial analysis of models, without dependency on the original CAD system, ensuring an objective evaluation

- Multi-format compatibility: support for major CAD systems (CATIA, NX, Creo, SOLIDWORKS, Inventor) and neutral formats (STEP, JT, 3D PDF)

- Interactive reports: generation of detailed documentation allowing precise identification of problems and their resolution

The solution offers comprehensive coverage of different aspects of validation, from geometric integrity to verification of annotations and PMI, including analysis of assembly structures.

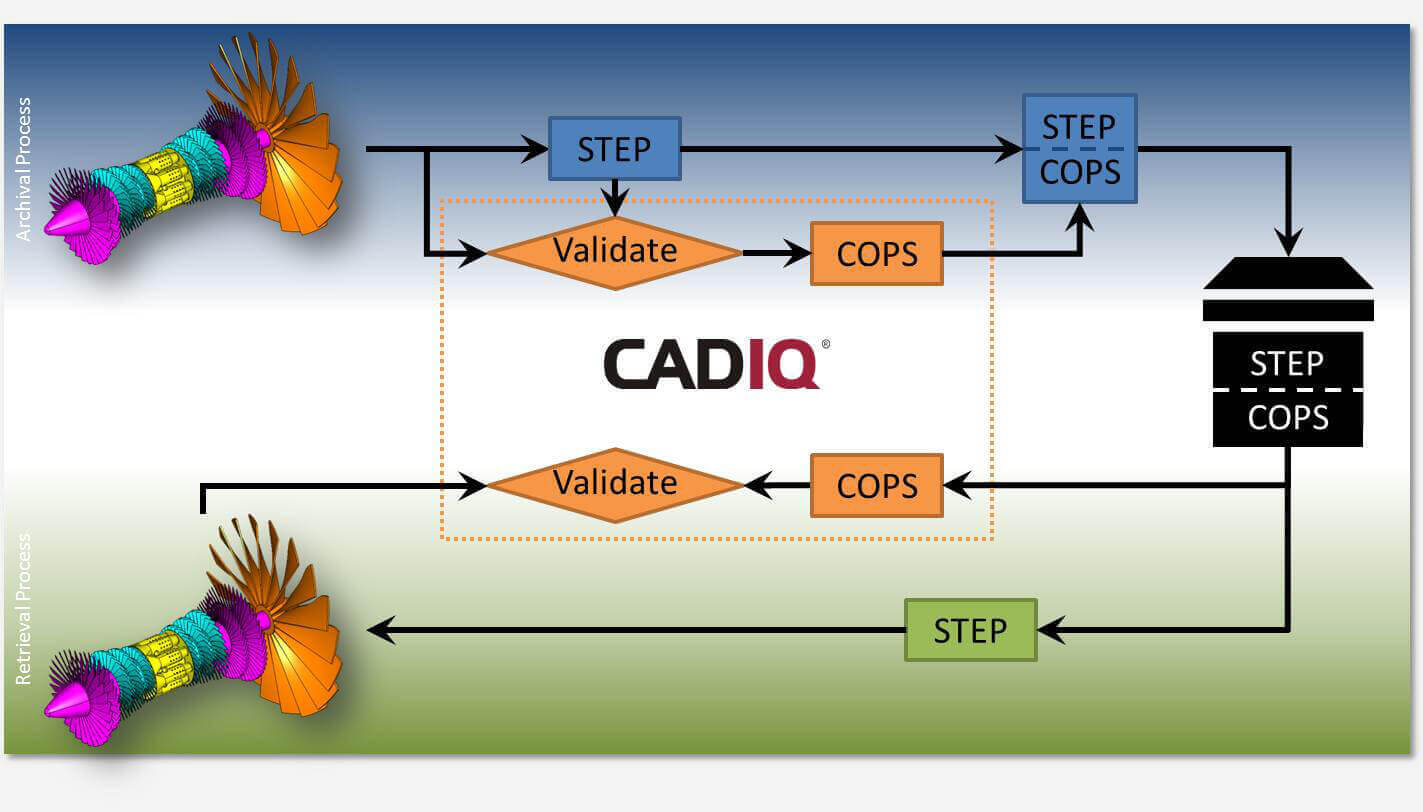

Qualification process with CADIQ

The data qualification process for archiving with CADIQ revolves around several complementary steps:

- Identification of significant geometric defects (degeneracies, discontinuities, topological problems)

- Detection of unrealistic features that could compromise future manufacturability

- Verification of PMI and annotation integrity (tolerances, symbols, references)

- Complete documentation of identified problems for later use

Each step relies on specialized algorithms that analyze models according to parameterizable criteria adapted to the specific requirements of each industry or application.

Comparison capabilities for conversion validation

One of the distinctive features of CADIQ lies in its ability to compare original models with their converted versions. This comparison allows:

- Evaluating geometric discrepancies between native and derived models

- Verifying the preservation of annotations and PMI after conversion

- Analyzing the preservation of complex assembly structures

- Precisely identifying modifications introduced during the conversion process

This functionality is particularly valuable in the context of long-term archiving, where the fidelity of models converted to neutral format must be rigorously verified.

Insertion of properties in STEP files

CADIQ allows enriching STEP files with validation properties essential for future verification of the integrity of archived models:

- Physical properties: automatic calculation and insertion of volumetric, surface, and mass properties

- Point clouds: intelligent sampling of surfaces for precise geometric verification

- Assembly properties: documentation of structure, positions, and orientations of components

- PMI certification: complete validation of annotations and associated attributes

These properties constitute a "digital signature" of the original model, allowing future users to verify data integrity during reuse, even after multiple conversions or migrations.

Integration into enterprise processes

To meet requirements for automation and integration in industrial environments, CADIQ offers several usage modalities:

- Intuitive graphical interface for ad-hoc analyses

- Batch mode via command-line interface for mass processing

- Possible integration with PLM systems for systematic validation

- Adaptable configuration according to different scenarios and requirements

This flexibility allows incorporating validation into established technical data lifecycle management processes, ensuring systematic qualification before archiving.

Practical applications and case studies

Validation for long-term archiving finds concrete applications in several industrial sectors where the durability of technical data represents a major strategic issue.

Application in the aerospace industry

The aerospace industry is a pioneer in adopting rigorous methodologies for validation and archiving of CAD data. With product lifecycles often exceeding 50 years, preserving model integrity is critical for maintenance, modifications, and certification.

Several aircraft manufacturers have implemented systematic validation processes before archiving:

- Complete verification of models before conversion to STEP AP242 format

- Insertion of validation properties for critical aerodynamic surfaces

- Detailed documentation of tolerances and annotations for manufacturing spare parts

- Certification of equivalence between native models and neutral formats

These processes integrate into a broader strategy for managing technical data throughout the lifecycle of aircraft, from design to dismantling.

Applications in the automotive industry

In the automotive sector, validation for archiving responds to several imperatives:

- Conservation of design data for spare parts (legal obligation of 10 to 15 years)

- Protection of technical intellectual property

- Reuse of existing designs for new models

- Traceability for product liability issues

Automotive manufacturers have developed specific approaches for validating tooling models and molds, particularly sensitive to geometric quality issues. Early detection of potential defects allows avoiding considerable costs during future reuse of models.

Experience feedback and measurable benefits

Organizations that have implemented rigorous validation processes for archiving report several tangible benefits:

| Benefit | Measured impact |

|---|---|

| Reduction of conversion failures | 85% decrease in problems when reusing archived models |

| Acceleration of production launch | 30% reduction in time needed to reuse existing designs |

| Improvement in part quality | 60% decrease in non-conformities related to model interpretation |

| Regulatory compliance | Significant risk reduction during certification audits |

These results underscore the importance of a methodical approach to validation as an essential component of any long-term archiving strategy.

Best practices and recommendations

The successful implementation of a validation strategy for long-term archiving relies on the adoption of proven best practices adapted to the specific context of each organization.

Establishment of a systematic process

Validation of CAD models for archiving must be part of a formalized and documented process:

- Definition of a clear archiving policy specifying objectives and requirements

- Establishment of validation criteria adapted to business specificities

- Implementation of a qualification workflow integrated into the PLM process

- Systematic documentation of validation results

- Periodic revision of criteria and methods based on technological developments

This process must be sufficiently flexible to adapt to different categories of data and their potential future uses.

Selection criteria for data to be archived

Not all technical data requires the same level of validation. A strategic approach consists of categorizing models according to their importance:

- Critical data: models defining interfaces, safety functions, or elements subject to certification (complete and rigorous validation)

- Significant data: important models for the global understanding of the product (validation of main aspects)

- Contextual data: secondary or reference models (simplified validation)

This hierarchization allows optimizing resources by concentrating validation efforts on models with higher added value or potential risk.

Frequency of archive verification

Long-term archiving is not a one-time operation but a continuous process. Archives must be periodically verified to guarantee their integrity:

- Routine checks after each technological migration

- Random verifications of representative samples

- Comprehensive tests during major changes in IT infrastructure

- Systematic validation before any significant reuse

These recurrent verifications allow early identification of potential degradations or access problems, before they compromise the usability of archives.

Team training

The success of a validation strategy for archiving also relies on the skills of the teams involved:

- Awareness of long-term archiving issues for designers

- Technical training on validation tools for data specialists

- Development of internal expertise on neutral formats and their specificities

- Sharing of best practices and experience feedback

Investment in skill development constitutes a key success factor, particularly in a field as technical as CAD model validation.

Evolution toward a proactive strategy

The most effective approach consists of integrating archiving considerations from the initial phases of model creation:

- Definition of modeling rules favoring interoperability

- Continuous quality verification throughout the development cycle

- Progressive certification of finalized elements

- Systematic documentation of design choices

This proactive approach considerably reduces validation efforts during final archiving and improves the overall quality of produced models.