In a bottling plant, an operator faces an HMI screen displaying a simple error code: "E1024." A treasure hunt ensues: paper manual in hand, he attempts to locate the faulty sensor among hundreds of components. The result? Thirty minutes wasted, production at a standstill, and tension rising. This scenario, still common until recently, illustrates how 3D visualization integrated into HMIs is transforming everyday industrial life.

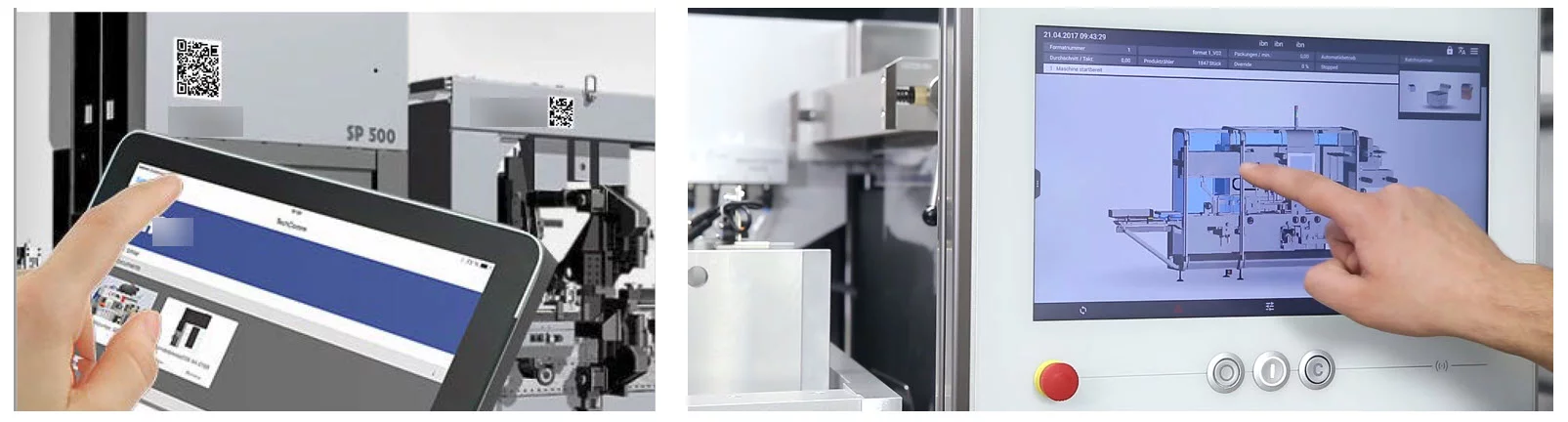

Today, a simple click on an interactive model is all it takes to immediately locate the affected part, access contextual documentation, or view sensor status in real time. Thanks to solutions like 3DViewStation, operators no longer simply read codes or navigate abstract menus: they interact directly with a faithful and dynamic representation of their machine. The result: accelerated diagnostics, fewer interpretation errors, and more efficient interventions—a silent but decisive revolution for the connected industry.

Table of contents

- The evolution of Human-Machine Interfaces: beyond traditional control

- Technical challenges of CAD integration in industrial HMIs

- Why 3D visualization transforms the operator experience

- Essential criteria for a CAD visualization solution in industrial environments

- 3DViewStation: a solution adapted to modern HMI requirements

- Successful integration methodology: key steps and best practices

- Measurable benefits and return on investment

- Future perspectives: towards intelligent and predictive interfaces

The evolution of Human-Machine Interfaces: beyond traditional control

Human-Machine Interfaces have evolved considerably since their beginnings. Initially limited to physical control panels with buttons and indicator lights, they gradually transformed into touch screens and graphical interfaces. Today, industry already equips medium to large machines with integrated computers with their own screens to control and monitor operations.

However, these interfaces often remain confined to schematic representations, text menus, and numerical indicators that do not reflect the physical reality of the machine. This limitation creates a cognitive gap for operators who must constantly make the correspondence between the abstract information displayed and the actual components of the equipment.

Industry 4.0 and the digital transformation of factories are pushing for a fundamental rethinking of this approach. Machine design data – primarily in 3D – already exists and is used during the development phase. Paradoxically, these valuable visual representations are rarely utilized in the interface used daily by operators.

This disconnection between design data and the operational interface represents a significant opportunity for improvement. By bringing these two worlds together, it becomes possible to create a more intuitive, efficient user experience better adapted to modern operational challenges.

Technical challenges of CAD integration in industrial HMIs

The integration of 3D CAD visualizations in Human-Machine Interfaces faces several major technical challenges. These obstacles partly explain why many companies have not yet taken the step toward visually enriched HMIs, despite the obvious benefits.

Complexity of CAD formats and compatibility

The first challenge concerns the diversity of CAD formats. 3D models are generally created in specialized software such as CATIA, SolidWorks, Creo, or Inventor, each using its proprietary format. This heterogeneity complicates direct integration into HMI systems that require formats optimized for real-time display rather than for design.

The conversion and optimization of CAD models for use in an interactive interface represent a complex process requiring specific technical expertise. Without the right tools, this step can become a bottleneck in HMI development.

Performance and system resources

Complete CAD models often contain extremely precise details which, while necessary for manufacturing, can unnecessarily overload an HMI system. Industrial embedded computers that drive these interfaces typically have limited resources compared to engineering workstations.

The fluid display of complex 3D models requires significant optimization – particularly through polygonal reduction and management of levels of detail – to maintain acceptable performance without compromising the visual quality essential to understanding the machine.

Integration with existing control systems

HMIs are not isolated systems but integrate into a broader ecosystem of control and automation. Adding 3D visualization must be done transparently, without disrupting existing critical functionalities.

This integration involves challenges in communication between the visualization component and the control system, particularly for real-time representation of the state of sensors, actuators, and other dynamic elements of the machine.

Why 3D visualization transforms the operator experience

Despite the technical challenges, integrating 3D CAD visualizations in HMIs brings considerable advantages that fully justify the investment. These benefits manifest at several levels of industrial operation.

Immediate spatial understanding

The three-dimensional representation of machines allows operators to instantly understand the spatial arrangement of components. This intuitive understanding significantly reduces cognitive load compared to traditional schematic representations.

By visualizing an exact replica of the machine they operate, users can precisely locate elements mentioned in alerts or maintenance procedures, without having to interpret abstract diagrams or consult separate manuals.

Accelerated visual diagnosis

During a malfunction, 3D visualization allows for quickly identifying the source of the problem. Sensors and measurement points can be represented directly on the model, with a color code indicating their status and highlighting anomalies.

This visual approach to diagnosis significantly reduces the time needed to locate a problem, particularly in complex machines with numerous similar or difficult-to-access components.

Integrated and contextual documentation

3D visualization allows technical documentation to be directly associated with visible components. Rather than consulting separate manuals, the operator can instantly access relevant information by simply selecting the concerned element on the model.

This contextual integration of technical data (specifications, maintenance procedures, intervention history) transforms the HMI into a true center of operational knowledge.

Essential criteria for a CAD visualization solution in industrial environments

Choosing a 3D visualization solution for integration in an industrial HMI must meet specific criteria that go beyond the usual considerations for standard CAD visualization applications.

| Criterion | Importance in industrial environment | Operational impact |

|---|---|---|

| Performance on limited hardware | Critical | Interface fluidity even on embedded systems |

| Multi-format CAD compatibility | High | Integration without complex conversion |

| Robust integration API | Essential | Transparent communication with the control system |

| Automatic model optimization | Important | Reduction of system load without manual intervention |

| Interactivity adapted to industrial context | Necessary | Usability with constraints (gloves, environment) |

| Stability and robustness | Critical | Reliability in 24/7 production environment |

The ideal solution must offer an optimal balance between functional richness and integration lightness. It must also be designed with a deep understanding of the specific constraints of industrial environments.

Advanced visualization capabilities

Beyond the basic display of 3D models, a solution adapted to industrial HMIs must offer advanced features such as:

- Dynamic sections and exploded views to examine the interior of assemblies

- Rendering modes adapted to different needs (realistic, technical, schematic)

- Intelligent management of levels of detail according to the context of use

- Animation of mechanisms for movement simulation

- Visual highlighting of components related to alerts or interventions

These capabilities transform visualization into a true operational decision support tool rather than a simple static representation.

3DViewStation: a solution adapted to modern HMI requirements

Facing the challenges of integrating CAD visualization in human-machine interfaces, 3DViewStation positions itself as a solution particularly adapted to industrial environments. Developed for over 25 years, this technology specifically addresses the requirements of professional HMI applications.

Architecture optimized for integration

Unlike many alternative solutions that require complex adaptations, 3DViewStation was designed from the start to integrate easily into third-party applications. It is not a simple SDK (Software Development Kit) but a standalone application that can be fully incorporated into the user interface of an existing application.

This approach significantly reduces integration efforts and allows for quickly achieving concrete results. Developers can thus focus on business functionalities rather than on the complexities of 3D visualization.

Exceptional performance on industrial hardware

3DViewStation offers remarkable performance even for very complex CAD assemblies. This characteristic is particularly important in the context of industrial HMIs where hardware resources may be limited and interface fluidity is essential.

Automatic model optimization, including intelligent polygonal reduction and dynamic management of detail levels, allows for an optimal balance between visual quality and interface responsiveness.

Extended compatibility with industrial CAD formats

One of the major assets of 3DViewStation lies in its ability to natively handle a wide range of industrial CAD formats. This compatibility eliminates conversion problems and data loss that frequently occur when integrating 3D visualizations in HMIs.

Original CAD models can thus be reused directly, ensuring an exact correspondence between the visualization in the HMI and the actual machine, including for specific configurations.

Successful integration methodology: key steps and best practices

The successful integration of 3D CAD visualizations in a human-machine interface relies on a structured methodology that takes into account both technical aspects and the needs of end users.

Preliminary analysis and definition of objectives

The first step consists of clearly defining the operational objectives of 3D integration. This analysis should identify:

- Specific tasks that will benefit from 3D visualization

- Critical information to be visually represented

- Necessary interactions between the visualization and the control system

- Performance indicators that will allow evaluating the success of the integration

This initial phase is essential to avoid information overload and focus effort on aspects that will bring tangible added value to operators.

Preparation and optimization of CAD models

Existing CAD models generally need to be adapted for use in the HMI. This preparation includes:

- Simplification of non-essential geometries to improve performance

- Hierarchical organization of components to facilitate navigation

- Definition of visual attributes (colors, transparencies) to improve readability

- Identification of points of interest for automatic navigation

With 3DViewStation, this process is greatly simplified thanks to automatic optimization tools that preserve essential information while reducing model complexity.

Progressive technical integration

The recommended approach for technical integration consists of proceeding in steps:

- Basic integration of static 3D visualization

- Addition of interaction functionalities (rotation, zoom, selection)

- Connection with real-time data from the control system

- Implementation of advanced features (animations, scenarios, documentation)

This progression allows validating each level of integration before adding new complexities, thus securing development and facilitating identification of potential problems.

Measurable benefits and return on investment

The integration of CAD visualizations in human-machine interfaces represents an investment that can be evaluated according to several measurable performance indicators.

Reduction of intervention times

The most immediate and quantifiable impact concerns the reduction of intervention times during maintenance operations or problem resolution. Data collected from companies having implemented this approach show:

- An average reduction of 40% in the time needed to locate a defective component

- A decrease of 25% to 30% in the total duration of maintenance interventions

- A significant acceleration of initial fault diagnosis

These time savings translate directly into a reduction of machine downtime and thus an improvement in the operational availability of equipment.

Improvement of intervention quality

Beyond speed, 3D visualization also contributes to improving the quality of interventions:

- Reduction of component identification errors

- Decrease in collateral damage during interventions

- Better compliance with recommended procedures

- More accurate documentation of performed interventions

This qualitative improvement has a direct impact on equipment lifespan and overall reliability of installations.

Optimization of training costs

The pedagogical dimension of interfaces enriched by 3D visualization also generates substantial savings on training costs:

- Reduction of 40% to 60% in the time needed to train a new operator

- Decrease in the need for assistance by expert technicians

- Possibility of self-training on certain procedures

- Better retention of technical knowledge

These benefits are particularly important in the current context of technical skills shortage and generational renewal in industry.

Future perspectives: towards intelligent and predictive interfaces

The integration of CAD visualizations in human-machine interfaces is only a first step towards more intelligent and proactive systems. Future developments open fascinating perspectives for the evolution of these interfaces.

Convergence with artificial intelligence

The next generation of human-machine interfaces will combine 3D visualization and artificial intelligence to create truly cognitive systems:

- Predictive diagnosis based on historical data analysis and visualization of critical components

- Proactive maintenance recommendations with visual simulation of interventions

- Dynamic adaptation of the interface according to context and user habits

- Virtual assistance capable of interpreting operator intentions

This convergence between advanced visualization and AI will allow moving from reactive interfaces to truly anticipatory systems, capable of foreseeing operator needs.

Integration of augmented and virtual reality

The future of human-machine interfaces will also include deeper integration with augmented and virtual reality technologies:

- Overlay of contextual information directly on the view of the actual machine

- Immersive training using CAD models in virtual environments

- Remote assistance with sharing of 3D visualization between experts and field operators

- Simulation of complex interventions before execution on the actual equipment

These technologies will create a continuum between virtual representation and physical equipment, further facilitating understanding and interaction.

Towards a unified user experience

Ultimately, the goal is to create a totally unified user experience where the distinction between virtual model and real machine fades for the operator:

- Single interface for design, simulation, operation, and maintenance

- Continuity of information throughout the equipment lifecycle

- Fluid collaboration between different stakeholders

- Seamless integration with enterprise systems (ERP, PLM, MES)

This holistic vision represents the logical outcome of the integration between CAD visualization and human-machine interfaces, creating a complete digital environment that accompanies the physical equipment throughout its existence and maximizes its operational value.