There will always be differences between the design model and the manufacturing model. Zero article inspection (ZAITM) answers the important and potentially costly question: Are differences between the design and manufacturing model acceptable?

What is zero article inspection?

First article inspection is the first physical part from a manufacturing line. The purpose of first article inspection is to ensure the “as built” part matches the “as designed” part, typically represented by a released CAD model in the PDM system – the “master” design model.

In a digital enterprise or MBE environment, before producing a physical part, the last digital representation of that part is the 3D geometry and PMI available prior to tool path generation, machine coding, or chip cutting.

In a digital enterprise or MBE environment, the objective is to directly reuse the “master” model, containing both geometry and product and manufacturing information (PMI), for downstream purposes. However, the downstream functions often don’t use the “master” model itself, but instead use some derivative of that model. Depending on how the data is handed off between design and manufacturing, the “master” model may be translated or even completely remodeled, creating a disconnect between the design and the manufacturing models, and increasing the potential for variation of the geometry and/or the PMI between the two models.

If the first physical part off the line goes through “first article inspection”, it makes sense to call the review of the last digital representation of a part – the model used by the manufacturing or inspection software, “Zero Article Inspection™” since it comes just before the first article is produced.

Zero Article Inspection™, or ZAI™, is a concept coined by the experts at ITI, as a result of close collaboration with customers, PLM vendors and industry consortia. ZAI aims to ensure that the manufacturing model used to generate tool paths or inspection routines matches the “master” design model, or at least that any differences between the two models are identified and deemed to be insignificant.

So, another way to think of it is that FAI compares the physical output of the manufacturing process – after the part is physically manufactured – with the as designed-model, while ZAI compares the digital output of the manufacturing process – before anything is physically manufactured – with the as-designed model.

Variations in the nominal geometry and PMI (product and manufacturing information) handed off between design and manufacturing raise the question, “Why?” Suddenly, revision control issues, methods of incorporating changes, and potential for downstream modeling changes are evident. This is why zero article inspection is important, if not critical, to any MBE process.

ZAI is a critical step in a product’s lifecycle - at the intersection of design and manufacturing - where the geometry and PMI can be scrutinized and validated. It is early enough in the process for manufacturers and suppliers to realize significant time, cost, and quality benefits -- and most importantly to avoid FAI failure caused by design to manufacturing model changes.

The digital twin analogy

A July 13, 2017 article in The Economist explains the digital twin evolution, and how millions of things will soon have digital twins. Zero article inspection is analogous to a validation of the digital twin.

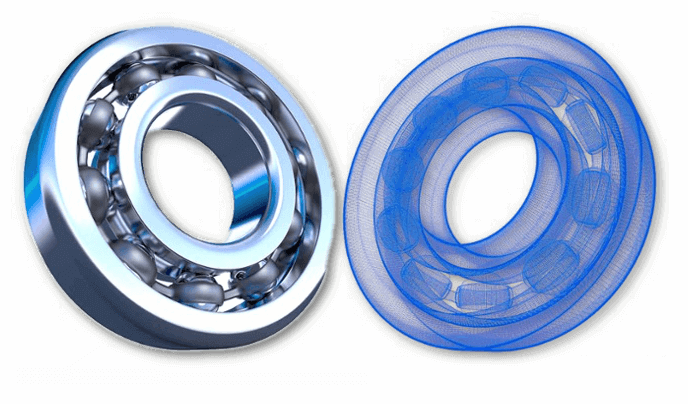

If manufacturing and design models are equivalent, they contain only negligible variations and will pass first article inspection. But like human identical twins, a digital twin may have slight yet significant differences that are not apparent on visual inspection. Therefore, engineers need a way to discern if the variations in 3D models are significant or negligible before first article inspection.

Why not just rely on first article inspection?

Before we delve further into ZAI, let’s take a closer look at first article inspection. The first article inspection process (also referred to as “nominal article inspection” or “digital article inspection”) involves manufacturing a physical part and inspecting the initial physical part to ensure that it satisfies all requirements specified in the engineering design on a “pass-fail” basis.

When a part fails first article inspection, delays in the overall schedule are expected and rework is usually required both upstream and downstream. If the first parts are supposed to roll into your second, third, or hundredth parts, then you appreciate the exponential – and potentially very costly - impact of such a delay.

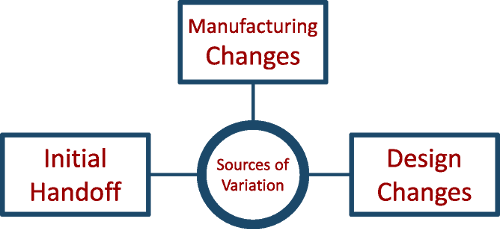

Sources of CAD model variation

When the 3D model is moved through the digital enterprise, there are several sources of variation that can be introduced between design and manufacturing. The 3D design model and the 3D manufacturing model should be digital twins with only negligible variations. Issues such as out of synch versions, diverging modifications, and human negligence typically are not identified until first article inspection. And if they are missed, they can cause expensive product warranty issues, product recalls, or worse.

When ZAI is added to your manufacturing process, model variations can be identified early, and dispositioned more efficiently and at a much lower cost than after FAI or later

It is important to note that when we talk about a CAD model, we mean 3D geometry representing a nominal shape. When we talk about an MBD (model-based definition) model, we mean 3D geometry representing a nominal shape plus 3D PMI that represents the allowable variation in the nominal shape. These sources of variation apply whether you’re using CAD or MBD models.

1. Initial handoff

Translation changes made to the digital model during the initial handoff from design to manufacturing

- Translation – If the format of the model between design and manufacturing is different, then by definition there must be a translation. And, this can lead to translation errors. These can be errors with the 3D geometry, or with the 3D PMI, or with both.

- Remodeling – This presents a more significant potential for variation than translation. If design model geometry or PMI gets downgraded to a 2D drawing, or to a 3D graphical representation, the manufacturing team must rebuild the 3D model from the 2D model or from the 3D graphical model. Remodeling can introduce more dramatic variations because remodeling introduces the potential of human interpretation, and thus human error.

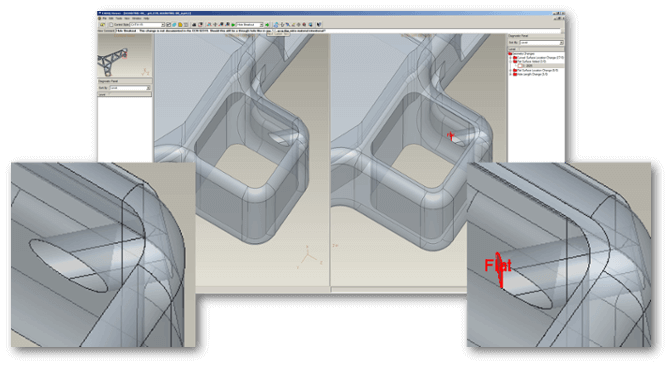

An unintentional change to a hole is identified by CADIQ (on right).

2. Manufacturing changes

Changes made to the digital manufacturing model after the initial handoff

- Some manufacturing changes are anticipated. For example, the design team may specify in the PMI where manufacturing can break edges with a radius or add a draft angle but these details may not be modeled by the design team. These are acceptable and anticipated changes that the manufacturing team can make without violating the design requirements of the part.

- Some manufacturing changes are not anticipated but introduced as a result of limitations in the manufacturing systems or processes relative to the design requirements. These changes are made in order to make the model work for a particular manufacturing process. Manufacturing may decide these changes are negligible, and thus not document or communicate them. The risk is that these changes might violate a design requirement known to the design team but not fully communicated to the manufacturing team.

- Sometimes manufacturing makes a change and thinks it might have impact on design intent, but for many whatever reason, does not document and communicate the change to the design team in time for their feedback to be considered.

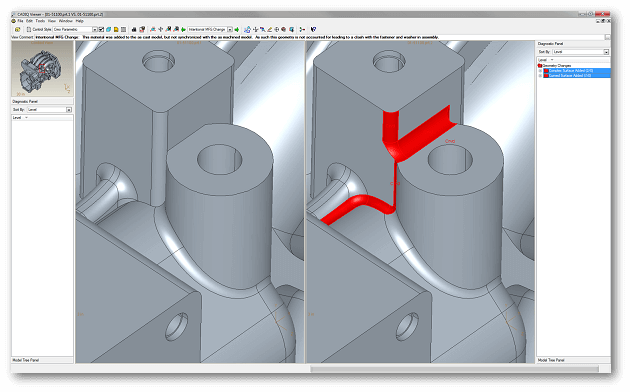

Manufacturing change example: Material added to cast model did not synchronize with machined model.

3. Design changes

Changes made to the digital design model after the initial handoff

- Some design changes may not be well documented and thus the manufacturing team may interpret them differently than the design team intended.

- Any undocumented design changes – intentional or otherwise - will naturally be completely missed by manufacturing.

- Design changes that, for whatever reason, are not incorporated into the manufacturing model will produce significant variation.

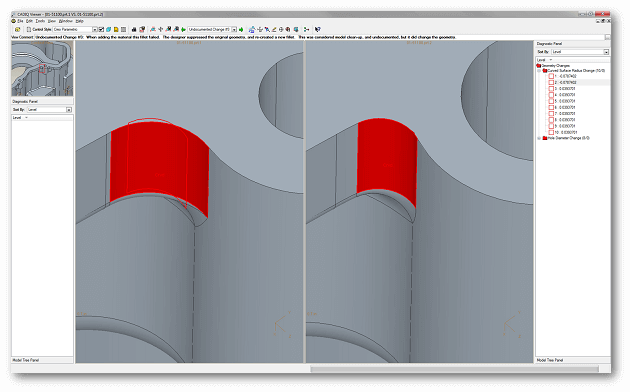

Design change example: When adding material, this fillet failed. The designer suppressed the original geometry, and then re-created a new fillet. This was considered model clean-up and was undocumented.

Regardless of where, how, or who makes a change to the design or manufacturing model, these sources of variation are possible whether the product lifecycle environment is multi-CAD or single-CAD, and whether the manufacturing team is directly reusing a design model or remodeling it. The effect can be minimized in a single-CAD environment but never completely eliminated.

The bottom line is that there will always be differences between identical twins – between the design model and the manufacturing model. Zero article inspection answers the important and potentially costly question: Are differences between the design and manufacturing model acceptable?

Manufacturers who wish to optimize the digital enterprise, avoid non-value-added rework, and avoid downstream costs, need to embrace zero article inspection. They need a process to identify variations before first article inspection; and they need to address any significant variations before any physical manufacturing is done.