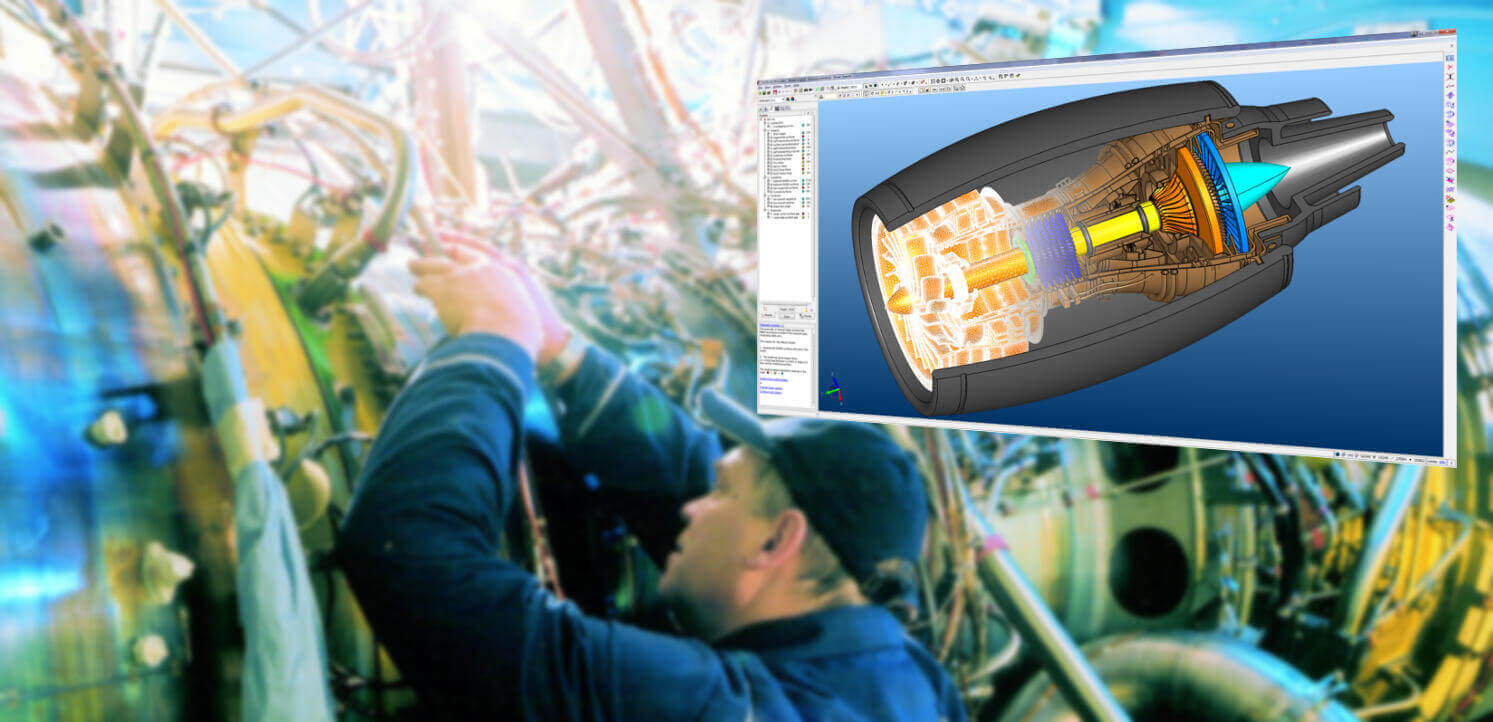

CAD interoperability represents a major challenge for modern industrial companies. Conversion errors, topological issues, and incompatibilities between native formats generate considerable time losses and high manual rework costs. To address these challenges, CADfix offers three specialized standalone solutions that automate the repair, simplification, and preparation of CAD models to meet the specific requirements of each application area.

The Challenge of CAD Automation in Enterprises

Automated CAD repair and CAD conversion processes have become critical in an environment where companies handle hundreds of models from multiple sources daily. SASIG, VDA, and JAMA industry quality standards impose accuracy standards that require rigorous validation of CAD models. The exchange of CAD data between different systems frequently generates geometric errors and topological problems that directly impact the productivity of technical teams. These malfunctions result in extended delivery times and measurable operational overheads.

Common Issues

- • Geometry errors

- • Format incompatibilities

- • Manual rework time

- • Loss of model integrity

Three specialized solutions for distinct needs

CADfix DX

Universal solution for geometry repair and multi-format translation. Automates geometry healing to ensure the integrity of CAD models in CAE simulation and analysis workflows.

See ProductCADfix PPS

Specialized solution for simplifying complex CAD models in the plant & process industry. Optimizes large assemblies for factory design and shipbuilding systems.

See ProductCADfix VIZ

Dedicated optimization solution for visualization and immersive applications. Converts CAD models into mesh representations optimized for virtual, augmented, and mixed reality.

See ProductQuantified Business Benefits

Productivity Gains

70% reduction in model preparation time for simulation thanks to CAD automation and integrated batch processing.

Enhanced Quality

Guaranteed compliance with industry standards with Automatic validation of native CAD formats and complete traceability of modifications.

This approach allows companies to precisely select the solution that best meets their technical challenges, thus optimizing their investment and their CAD defeaturing and geometric optimization processes.

Selection Criteria

- Target Application Area

- Type of Models Processed

- Simplification Objectives

- Target Systems

Discover the solutions in detail

Deepen your knowledge of each CADfix solution with our detailed technical analyses: