5 minutes to convert a CATIA assembly to universal format, reduced to 1 second through automation. KISTERS Automation Server eliminates repetitive CAD conversion tasks that consume 20% of technical teams' time. This server platform automatically processes thousands of CAD files, generates PLM thumbnails, and synchronizes enterprise systems 24/7, freeing engineers for high-value-added tasks.

KISTERS Automation Server (KAS): Intelligent Automation of 3D Processes

KISTERS Automation Server (KAS) represents a cutting-edge solution for automating 3D data-related processes in enterprise environments. This powerful platform enables organizations to significantly optimize their workflows by automating repetitive CAD model processing tasks, freeing up resources for higher value-added activities.

Designed to integrate seamlessly into existing digital ecosystems, KAS offers exceptional flexibility thanks to its service-oriented architecture. This modular approach allows companies to precisely customize their automation processes according to their specific needs and technical infrastructure.

Robust Server Architecture

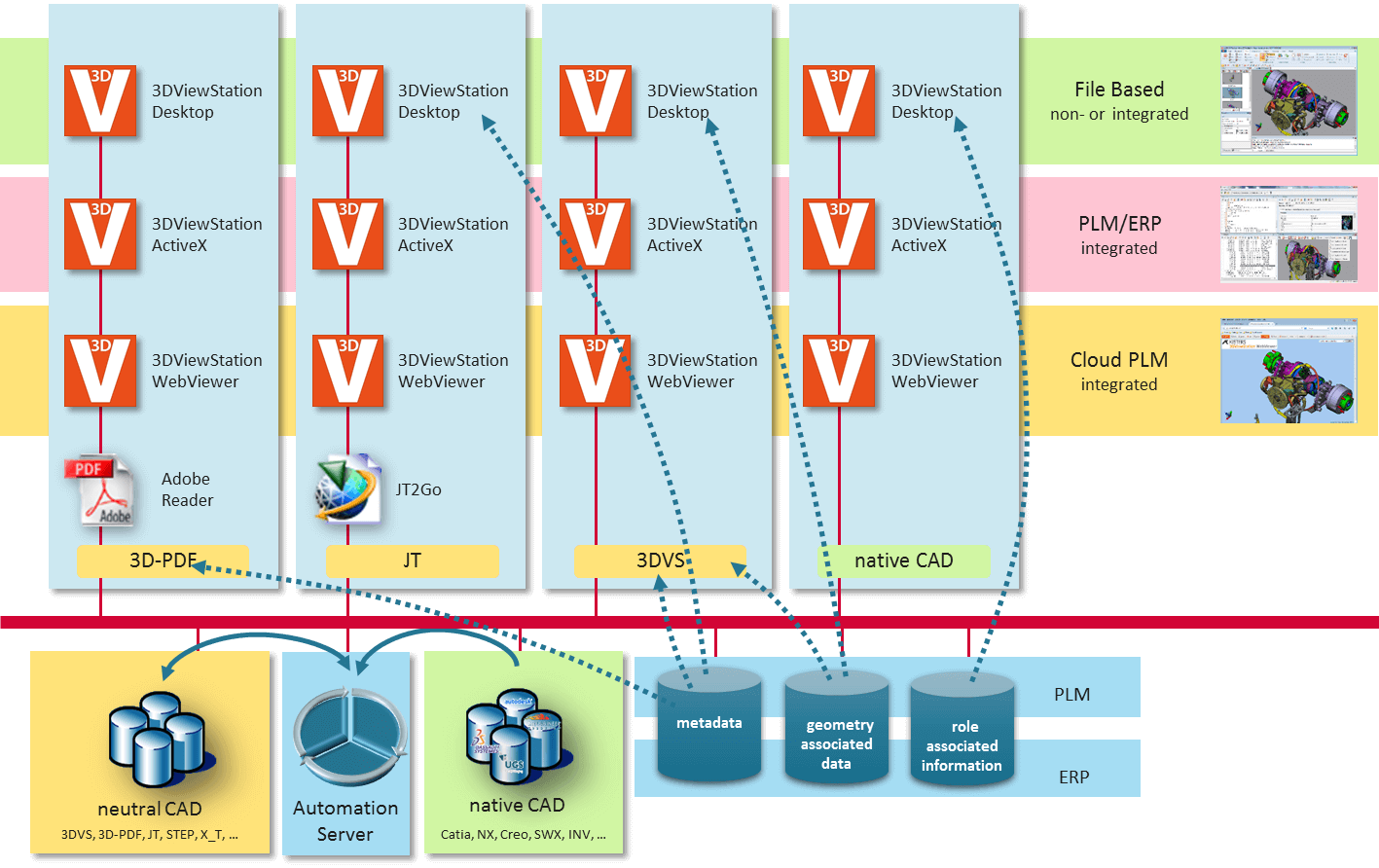

KAS functions as a background Windows service, automatically processing CAD files without manual intervention. Its client-server architecture allows efficient workload distribution and seamless integration with existing enterprise systems such as ERP, PDM, and PLM.

Integration Flexibility

With its comprehensive REST APIs and WebSocket interfaces, KAS can easily connect to virtually any enterprise application. This flexibility ensures end-to-end automation of business processes involving 3D data.

Advanced Features for 3D Process Automation

KISTERS Automation Server (KAS) offers a comprehensive set of features designed to address the complex challenges of CAD data processing in enterprise environments. Building on the proven technologies of the 3DViewStation suite, KAS extends these capabilities in a server automation context, enabling massive and unattended 3D data processing.

| Feature | Description | Benefit |

|---|---|---|

| CAD Format Conversion | Automated transformation between more than 50 native and neutral CAD file formats | Elimination of format incompatibilities and streamlining of data exchanges |

| 2D View Generation | Automatic creation of technical documentation from 3D models | Significant reduction in time spent on technical documentation |

| Geometric Analysis | Automated extraction of measurements, volumes, and other geometric properties | Quick access to critical information for engineering decisions |

| Batch Processing | Ability to process thousands of files without human intervention | Economies of scale and elimination of bottlenecks in processes |

One of KAS's main strengths lies in its automation flexibility. The solution adapts to each company's specific workflows, whether it's automatically generating exploded views for technical documentation, converting entire component libraries to compatible web formats, or extracting key geometric data for ERP systems.

WebSocket Technology and REST API

KAS offers a modern and well-documented API that enables seamless integration with enterprise applications. This API-first approach ensures maximum flexibility in configuring automation processes and connecting with existing systems.

Use Cases and Automation Scenarios

KISTERS Automation Server (KAS) effectively solves a wide range of challenges related to 3D data processing in industrial contexts. Its versatility makes it a strategic tool for many departments within manufacturing and engineering organizations.

CAD Conversion Automation

Automatic transformation of files from proprietary CAD systems to neutral or specific formats to facilitate internal and external collaboration. This process eliminates bottlenecks related to format incompatibilities and significantly accelerates technical data exchanges.

- Batch conversion of CATIA, NX, SOLIDWORKS files to neutral formats

- Automatic transformation for supplier portals

- Feeding PLM systems with standardized formats

Automated Technical Publishing

Programmed generation of technical documentation, exploded views, and graphical representations from 3D models. This process significantly reduces the time needed to create and update product documentation.

- Automatic creation of isometric views for catalogs

- Generation of exploded views for maintenance manuals

- Production of high-quality renders for marketing materials

Geometric Analysis and Data Extraction

Automatic extraction of critical information such as dimensions, volumes, surfaces, and other geometric properties to feed enterprise systems. This automation ensures data accuracy and eliminates human errors.

- Automatic volume calculation for material estimation

- Bill of Materials (BOM) extraction for ERP systems

- Interference analysis for design validation

Manufacturing companies use KAS to automate repetitive 3D model preparation tasks that traditionally consume hundreds of hours of manual work. For example, an industrial equipment manufacturer was able to reduce the time needed to prepare models for its electronic catalogs by 90%, while improving data accuracy and consistency.

Technical Architecture and Integration in the Enterprise Ecosystem

KISTERS Automation Server (KAS) stands out for its advanced technological architecture that provides exceptional flexibility and robustness for CAD process automation. Designed as a centralized server solution, KAS naturally integrates into existing enterprise infrastructures, ensuring smooth adoption and rapid return on investment.

System Architecture

KAS functions as a robust Windows service capable of simultaneously processing multiple requests. Its modular design allows for horizontal and vertical scalability, adapting to the changing needs of organizations:

- Windows service running in the background 24/7

- Multi-thread architecture for optimal parallel processing

- Intelligent queue system for priority management

- Advanced error recovery mechanisms

- Detailed logging for operation tracking and auditing

Integration Options

Integration flexibility is one of KAS's major assets, enabling end-to-end automation of business processes involving 3D data:

- Complete REST API with Swagger/OpenAPI documentation

- WebSocket interface for bidirectional communications

- Directory monitoring for automatic file processing

- Predefined connectors for common PLM and ERP systems

- SDK for specific developments and advanced customizations

Data Security and Governance

KAS integrates robust security and data governance mechanisms, essential for enterprise environments handling sensitive information:

- Authentication based on modern standards (OAuth, SAML)

- Encryption of data in transit and at rest

- Integration with enterprise directory systems (LDAP, Active Directory)

- Comprehensive logging of access and operations for auditing

- Compliance with technical data governance policies

KAS's open and documented architecture allows IT teams and system integrators to develop custom automation solutions. Thanks to standardized APIs and configurable webhooks, KAS can become the central automation engine for all processes involving 3D CAD data within the extended enterprise.

Strategic Benefits for Businesses

The adoption of KISTERS Automation Server (KAS) generates tangible and measurable benefits for industrial organizations. By automating 3D data-related processes, companies gain significant advantages that go well beyond simple operational cost reduction.

| Dimension | Benefit | Measurable Impact |

|---|---|---|

| Productivity | Elimination of repetitive manual tasks | 70% to 90% reduction in time spent on CAD model processing |

| Quality | Process standardization and elimination of human errors | 85% decrease in errors related to technical data handling |

| Agility | Ability to quickly process large volumes of data | 30% to 50% reduction in time-to-market |

| Collaboration | Improved technical data exchanges | 40% acceleration of review and validation cycles |

| Economic | Reduction in operational costs and better resource allocation | Typical ROI between 6 and 12 months depending on implementation scale |

Automating CAD processes frees up valuable technical resources that can be reassigned to higher value-added activities. Rather than spending hours converting formats, preparing models for publication, or extracting measurements, engineers can focus on innovation and product improvement.

Business Process Optimization

KAS enables rethinking and optimizing business processes involving 3D data. This digital transformation results in:

- Batch processing during off-hours, optimizing resource utilization

- Process standardization ensuring consistency and traceability

- Elimination of bottlenecks related to manual data processing

- Significant reduction in delays between development phases

Organizational Impact

3D process automation with KAS profoundly transforms work organization:

- Reallocation of technical talent to innovation activities

- Reduction in frustration related to repetitive and time-consuming tasks

- Improved collaboration between departments thanks to standardized data

- Increased capacity to manage activity peaks without additional resources

KAS Implementation and Deployment

KISTERS Automation Server (KAS) implementation follows a proven methodology that ensures rapid results while allowing for progressive evolution towards complete CAD process automation. This pragmatic approach minimizes risks and maximizes return on investment at each stage of deployment.

4-Phase Deployment Methodology

- Process Analysis and Mapping

Identification of manual processes related to 3D data that consume the most resources and generate bottlenecks. This phase allows precise quantification of potential gains and prioritization of use cases.

- Pilot Implementation

Deployment of KAS on a targeted high-impact process, allowing validation of the approach, refinement of configuration, and quick demonstration of automation value. This phase typically generates visible results within a few weeks.

- Progressive Extension

Expansion of the automation scope to other processes by capitalizing on the experience gained. This iterative approach allows continuous optimization of the solution and adaptation of workflows to specific needs.

- Industrialization and Integration

Complete integration of KAS into the ecosystem of enterprise applications (PLM, ERP, collaborative portals) to create end-to-end automated processing chains. This phase maximizes the organizational impact of automation.

Key Success Factors

Experience shows that certain elements are critical to successful KAS implementation and maximizing its impact:

- Involvement of end users from the initial phases

- Clear definition of key performance indicators (KPIs)

- Adequate training of technical and administrative teams

- Rigorous documentation of automated processes

- Responsive technical support during critical phases

- Clear governance for solution evolution

KAS deployment can be performed in different technical configurations depending on the organization's needs and constraints: on-premises installation, in a private cloud, or hybrid. This flexibility allows adapting the solution to the company's overall IT strategy while ensuring the performance necessary for processing voluminous CAD data.

Conclusion: Transformation of Engineering Processes Through Automation

KISTERS Automation Server (KAS) represents a significant advancement in the digital transformation of engineering processes. By automating 3D data processing, this solution directly addresses the major challenges faced by industrial companies: resource optimization, acceleration of development cycles, and improvement of technical data quality.

CAD process automation is not simply an incremental improvement – it represents a paradigm shift in technical data management. KAS allows organizations to eliminate manual low value-added tasks, standardize critical processes, and redeploy their technical talent toward innovation and strategic development activities.

In an industrial context where agility and operational efficiency are becoming determining factors of competitiveness, the intelligent automation offered by KAS establishes itself as an essential strategic lever. Companies adopting this approach gain a decisive advantage in terms of speed, quality, and cost optimization in their engineering processes.

By fundamentally transforming how companies manage their 3D data, KISTERS Automation Server lays the foundation for more agile, collaborative, and ultimately more innovative engineering. Organizations that leverage these automation capabilities will be better positioned to address the complex challenges of modern industry and maintain their competitive advantage in an ever-evolving environment.