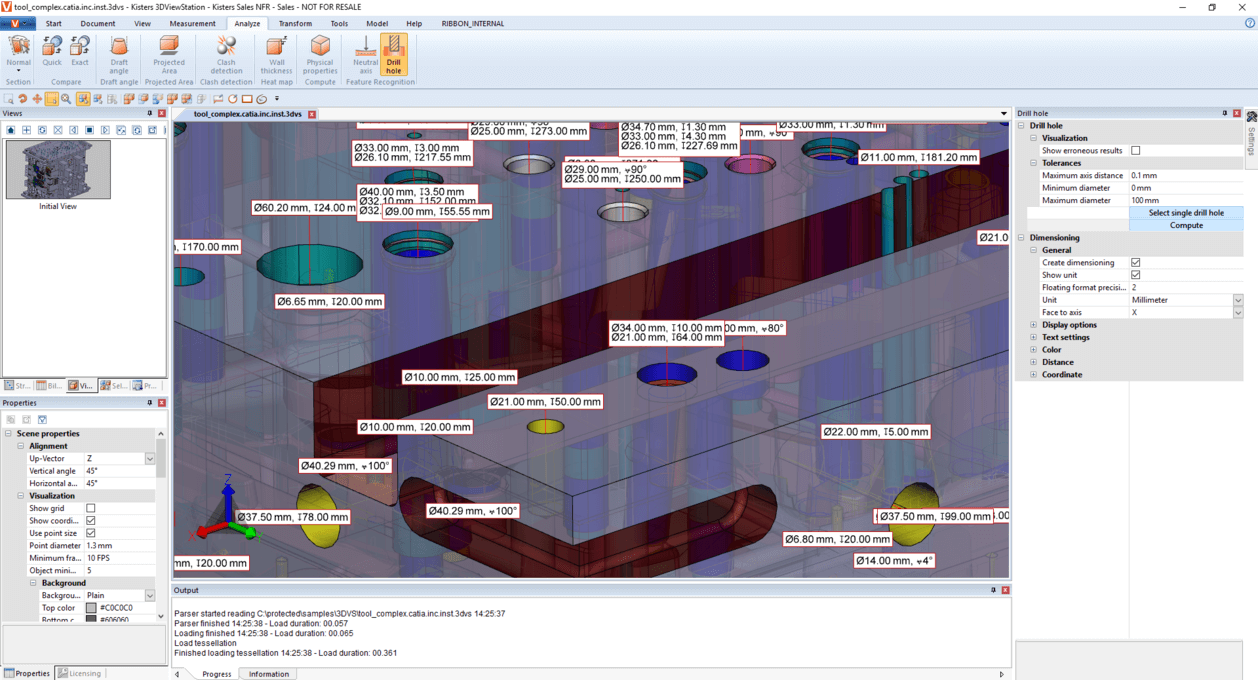

"Four hours wasted manually measuring 237 holes on an engine assembly," sighed Marc, an engineer at an automotive supplier. "And I discovered three errors in my final report." His colleague smiled: "Look at this." Three clicks later, 3DViewStation had automatically identified all the holes, calculated their diameters and depths, and generated a complete table. Total: 45 seconds.

This scene is repeated daily in industry. In a world where 35% of CAD analysis time is spent manually measuring holes, automatic hole recognition is radically transforming engineering processes. No more need for advanced CAD expertise or expensive licenses—a single click is all it takes to instantly extract all the essential hole data.

So why continue to use manual methods when this technology could save you thousands of hours a year?

Table of Contents

- Technical challenges of measuring drill holes in CAD models

- Limitations of traditional measurement approaches

- Automatic hole recognition technologies

- 3DViewStation: advanced drill hole recognition solution

- Concrete benefits and industrial applications

Technical challenges of measuring drill holes in CAD models

Precise hole analysis constitutes a critical step in the industrial value chain. These technical data directly influence manufactured product quality, CNC machine programming, and final component assembly. Three essential parameters must be measured with precision:

- The exact diameter of each hole

- The complete depth of the hole

- The angle of the hole bottom (for conical or countersunk holes)

Even a minimal measurement error can lead to costly consequences: defective parts, production delays, or assembly problems. In the aerospace industry, for example, drill hole measurement precision is subject to extremely strict tolerances, sometimes as low as 0.01 mm.

Limitations of traditional measurement approaches

Conventional hole analysis methods present several major disadvantages that slow down industrial processes:

- Dependence on expensive CAD licenses (several thousand euros per workstation)

- Need for in-depth technical expertise on native software

- Time-consuming manual process, particularly on complex assemblies

- High risk of human error in data interpretation

- Interoperability issues between different CAD systems

These limitations create a significant bottleneck in industrial workflows, confining access to technical data to CAD specialists only and slowing down communication between different departments.

Automatic hole recognition technologies

Automatic hole recognition technology relies on advanced geometric analysis algorithms capable of identifying cylindrical features in a 3D model. This process occurs in three key stages:

- Topological analysis of 3D geometry to identify cylindrical shapes

- Parametric recognition of geometric attributes for each hole

- Automatic extraction of critical dimensions (diameter, depth, angle)

This approach works even on tessellated geometries, not requiring access to the parametric construction tree of the original model. This independence from native data constitutes a major advancement for interoperability between technical systems.

3DViewStation: advanced drill hole recognition solution

The "Drill Hole Recognition" functionality of 3DViewStation represents a significant innovation in automating technical measurements. This solution enables instant identification and analysis of all drill holes present in a 3D model, regardless of its complexity.

The analysis process is remarkably intuitive:

- The user simply selects the "Drill Hole Recognition" function in the interface

- The system automatically detects all holes in the model

- A summary table displays all measured parameters for each hole

This functionality supports multiple CAD formats (CATIA, NX, SolidWorks, Creo, STEP, IGES...), ensuring optimal interoperability between different technical environments. The intuitive interface makes this technology accessible to all users, even without advanced CAD expertise.

Concrete benefits and industrial applications

Automating drill hole measurement generates measurable advantages in several industrial domains:

| Sector | Applications | Benefits |

|---|---|---|

| Aerospace | Analysis of complex structures with thousands of holes | 95% reduction in analysis time, increased reliability for certification |

| Automotive | Verification of engine blocks and assembly components | Smooth communication between design office and production |

| Mechanical | CNC programming for complex parts | Elimination of programming errors, 30% productivity gain |

In terms of operational impacts, this technology allows:

- A drastic reduction in analysis time (from several hours to a few seconds)

- Elimination of human errors in measurements

- Democratization of access to technical data for all departments

- Seamless integration of results into technical documentation

The ability to extract and export this data in standardized formats also facilitates their integration into PLM, ERP, or CAM systems, thus creating an essential digital continuity for Industry 4.0.

Companies that have implemented these solutions report an average 70% reduction in time devoted to hole analysis and a significant improvement in the accuracy of technical data transmitted to production workshops.

Automatic drill hole recognition thus constitutes a decisive advancement for optimizing engineering processes and ensuring excellence in the manufacturing of complex industrial components.