"Tuesday, 8:30 a.m. The car factory suddenly shuts down. 5,000 plastic parts are stuck in the molds, impossible to remove. Estimated cost: €120,000 in lost production and a 3-week delay. The cause? An insufficient draft angle of only 1.5° instead of the required 2.5°."

This catastrophic scenario, experienced by countless manufacturers, could have been avoided with a simple draft analysis during the design phase. As case studies show, a minimal difference in wall slope can turn a success into a costly disaster.

Draft analysis is a simple yet powerful preventative technique that accurately identifies problem areas before manufacturing, ensuring that each part can be removed from the mold without excessive friction or deformation.

What if a simple color code on your CAD model could prevent the next production shutdown?

Table of Contents

- Fundamentals of Draft Angle Analysis

- Impact of Negative Draft Angles on Manufacturing

- Traditional Methods of Draft Angle Analysis

- 3DViewStation: Optimal Solution for Draft Angle Analysis

- Practical and Industry Applications

- Practical Guide to Using 3DViewStation

- Economic and Operational Benefits

- Conclusion and Perspectives

Fundamentals of Draft Angle Analysis

Draft angle analysis, also called "draft angle analysis" in English, is a process of evaluating the inclination angles of a part's surfaces relative to the demolding direction. This analysis is fundamental to ensuring damage-free extraction of molded parts, whether for plastic injection molding, die casting, or other similar processes.

An adequate draft angle facilitates demolding by reducing friction between the part and the mold cavity. This inclination is generally expressed in degrees and varies according to the material used, geometric complexity, and surface requirements of the final part.

The classification of draft angles includes three main categories:

- Positive angles: Facilitate demolding by creating an inclination that eases extraction

- Neutral angles: Perpendicular to the demolding direction, presenting a moderate risk

- Negative angles (undercuts): Create obstacles to demolding, requiring specific solutions such as movable cores

The recommended angle values vary according to materials and processes, but here are some standard references:

| Material | Minimum Recommended Angle | Typical Application |

|---|---|---|

| Thermoplastics | 0.5° to 2° | Precision parts, electronic components |

| Thermosets | 0.5° to 1° | Electrical components, heat-resistant parts |

| Aluminum alloys | 2° to 3° | Housings, cases, automotive parts |

| Zinc alloys | 1° to 1.5° | Hardware parts, decorative components |

Impact of Negative Draft Angles on Manufacturing

Negative draft angles (undercuts) represent a major challenge in mold design and can cause numerous problems when not detected and addressed upstream. A negative draft angle is characterized by a negative angle that creates a mechanical obstruction preventing normal demolding of the part.

The consequences of undetected negative draft angles can be particularly costly:

- Degradation or breakage of parts during demolding

- Premature wear of molds

- Increased production cycle times

- Need to remake molds or add complex mechanisms

- Delays in bringing products to market

The average cost of a mold modification due to an unidentified negative draft angle can represent between 5,000 and 50,000 euros depending on the complexity of the part, not counting production delays and missed business opportunities.

Sectors particularly sensitive to negative draft angle problems include:

- The automotive industry for interior and exterior trim parts

- The consumer electronics sector for housings and casings

- Aerospace for certain non-structural components

- The medical sector for implantable devices and instruments

Traditional Methods of Draft Angle Analysis

Historically, draft angle analysis has been performed using various approaches whose effectiveness varies considerably. These traditional methods each present their advantages and limitations.

Manual evaluation, the first method used, consists of visually examining physical or digital models to identify problematic areas. This approach, while simple, presents obvious limitations:

- Imprecision inherent to human judgment

- Inability to quantitatively analyze exact angles

- High risk of oversights on complex geometries

- Time-consuming process on voluminous assemblies

Solutions integrated into native CAD software offer a more reliable alternative but present other constraints:

- Features limited to users with a full software license

- Variable performance depending on model complexity

- Sometimes complex integration into existing workflows

- High cost of complete CAD licenses for specific use

The major challenge lies in the ability to process heterogeneous CAD formats. In a typical industrial environment, data comes from multiple sources and formats (CATIA, SolidWorks, NX, Creo, etc.), requiring tedious and sometimes imprecise conversions between systems.

This interoperability issue between CAD formats can generate:

- Considerable time loss in conversions

- Risks of model degradation

- Incompatibilities leading to erroneous analyses

- Increased costs related to multiple software solutions

3DViewStation: Optimal Solution for Draft Angle Analysis

Faced with the limitations of traditional approaches, 3DViewStation stands out as a particularly suitable solution for draft angle analysis. This new generation CAD viewer combines performance, ease of use, and advanced features to meet the specific needs of manufacturing companies.

Developed by KISTERS, 3DViewStation offers an all-in-one approach that revolutionizes draft angle analysis in several ways:

- Native compatibility with over 30 CAD formats (CATIA, NX, Creo, SolidWorks, etc.)

- Exceptional performance allowing complex assemblies to be loaded in seconds

- Intuitive interface requiring no extensive training

- Precise and customizable draft angle analysis tools

- Significantly lower cost than complete CAD licenses

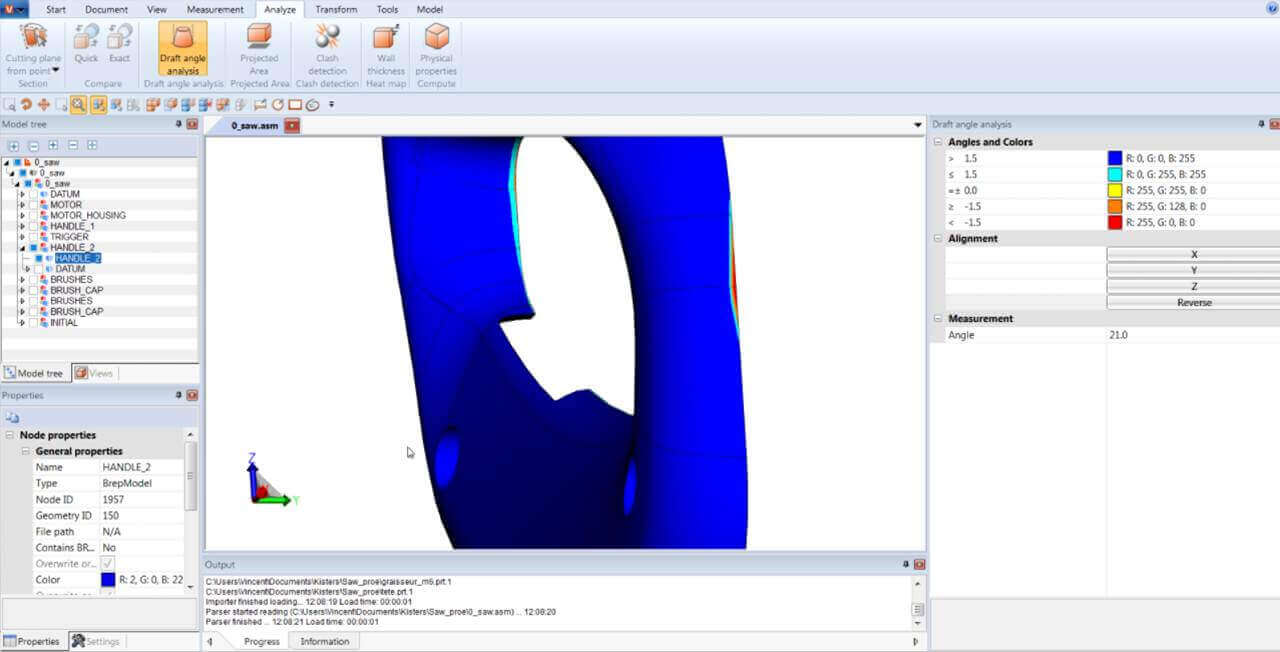

The Draft Angle functionality in 3DViewStation stands out for its relevance and flexibility. It allows instant visualization, via a customizable color code, of areas with insufficient angles or problematic negative draft angles.

The analysis process takes place in a few simple steps:

- Loading the CAD model (regardless of its origin)

- Selecting the Draft Angle tool in the analysis tab

- Defining the demolding direction (axis, vector, or geometric selection)

- Setting reference angles and color code

- Immediate visualization of results across the entire model

Unlike solutions integrated into traditional CAD software, 3DViewStation can be rapidly deployed to all teams involved in the manufacturing process, without requiring massive investments in licenses or training.

| Feature | Advantage for Draft Angle Analysis |

|---|---|

| Color visualization | Immediate identification of critical areas by color code |

| Flexible demolding direction | Ability to quickly test multiple demolding scenarios |

| Custom settings | Adaptation to the specific requirements of each project or material |

| Real-time analysis | Instant display of the angle when hovering over the model |

| Easy sharing | Export of results in multiple formats |

Practical and Industry Applications

Draft angle analysis with 3DViewStation finds concrete applications in many industrial sectors, each benefiting from specific features adapted to their constraints.

In the plastics industry, the precision of draft angle analyses is crucial for optimizing injection molds and ensuring the quality of produced parts. Manufacturers of plastic components use 3DViewStation to:

- Detect risk areas before mold manufacturing

- Optimize angles according to polymer characteristics

- Reduce cosmetic defects on appearance parts

- Improve plastic flow in the mold

A concrete case: an electronics equipment manufacturer reduced its mold development time by 35% by integrating 3DViewStation into its validation process. Negative draft angles, identified from the design phase, were corrected before mold manufacturing, avoiding costly rework.

In the metallurgical sector, specific constraints related to die casting or sand casting require a particular approach to draft angle analysis. The observed benefits include:

- Reduction of casting defects related to demolding problems

- Optimization of angles to compensate for alloy shrinkage

- Preventive analysis of areas likely to create thermal bridges

- Multi-material validation for composite parts

The aerospace and automotive sectors, where dimensional precision and aesthetics are paramount, also use 3DViewStation to ensure the manufacturability of complex parts:

- Validation of structural components in light alloys

- Analysis of trim parts with complex surfaces

- Optimization of tooling for series production

- Comparative quality control between theoretical model and actual part

Practical Guide to Using 3DViewStation for Draft Angle Analysis

The effectiveness of 3DViewStation for draft angle analysis is based on its ease of use and structured methodology. Here is a step-by-step guide to performing optimal analysis of your CAD models.

Model Preparation

Before launching the analysis, a few preparatory steps ensure accurate results:

- Import your CAD model into 3DViewStation using the native format without prior conversion

- Check the orientation of the model relative to the main axes

- Simplify if necessary the parts of the model not essential to the analysis

- Ensure that the model is "watertight" (without holes or geometric inconsistencies)

Draft Angle Analysis Configuration

The draft angle analysis tool in 3DViewStation is found in the "Analyze" tab. To configure the analysis:

- Select "Draft Angle" in the analysis menu

- Define the demolding direction by:

- Selecting a predefined axis (X, Y, or Z)

- Creating a custom vector

- Using an existing face or edge as reference

- Set the threshold angles and associated colors:

- Green: Favorable angles for demolding (typically > 3°)

- Yellow: Limit angles requiring attention (0.5° to 3°)

- Red: Problematic negative draft angles (< 0°)

- Adjust the analysis precision according to your needs

Interpreting Results

Once the analysis is launched, 3DViewStation instantly displays the results via a color code across the entire model. To effectively use this information:

- Use rotation and zoom tools to examine critical areas

- Activate the angle value display on hover for precise analysis

- Isolate problem areas by color filtering

- Take annotated screenshots to document problems

- Use measurement tools to quantify necessary modifications

Optimization and Iteration

Draft angle analysis is rarely a linear process. 3DViewStation allows rapid iteration by:

- Testing different demolding directions to identify the optimal orientation

- Adjusting angle thresholds according to the specific constraints of the project

- Comparing multiple versions of the same model to validate improvements

- Exporting results for communication with design teams

Economic and Operational Benefits

The adoption of 3DViewStation for draft angle analysis generates tangible benefits both economically and operationally. These benefits manifest in the short term and amplify with continued use of the solution.

Significant Reduction in Direct Costs

Investment in 3DViewStation presents a rapid return on investment thanks to several factors:

- Acquisition cost 70-80% lower than complete CAD licenses

- Flexible license model (permanent or subscription) adapted to different needs

- Reduced training costs thanks to an intuitive interface

- Decrease in late tooling modifications (average savings of €12,000 per project)

- Optimization of the number of specialized CAD licenses needed

An average company using 3DViewStation for draft angle analysis can save between €20,000 and €50,000 annually by combining direct savings on licenses and cost reductions related to design errors.

| Aspect | Traditional CAD Solution | 3DViewStation | Potential Savings |

|---|---|---|---|

| Average annual license cost | €8,000 - €15,000 | €1,500 - €3,000 | 75-80% |

| Required training | 3-5 days | 1/2 day | 80-90% |

| Average analysis time | 45-60 minutes | 5-10 minutes | 80-90% |

| Problem detection rate | 75-85% | 95-98% | 15-20% improvement |

Operational Benefits

Beyond direct savings, 3DViewStation transforms draft angle analysis processes by:

- Increased accessibility allowing more stakeholders to be involved in validation

- Drastic reduction in analysis times (average gain of 80%)

- Superior reliability of results minimizing the risk of error

- Facilitated collaboration between design offices and production workshops

- Centralization of analyses on a single multi-format platform

The exceptional performance of 3DViewStation with large assemblies constitutes a major competitive advantage. Where traditional solutions struggle to process complex models, 3DViewStation loads and analyzes files of several gigabytes in seconds, enabling rapid validation even on the most ambitious projects.

Conclusion and Perspectives

Draft angle analysis represents a critical step in the design and manufacturing process of molded parts. Its impact on final quality, costs, and production times makes it a major optimization lever for manufacturing companies.

In this context, 3DViewStation stands out as a particularly suitable solution through its unique combination of advantages:

- Exceptional performance on all types of CAD models

- Native compatibility with over 30 formats without prior conversion

- Intuitive interface accessible to all user profiles

- Precise and customizable draft angle analysis tools

- Unmatched value for money in the market

The constant evolution of manufacturing technologies, particularly 3D printing and new composite materials, raises new challenges in terms of manufacturability analysis. 3DViewStation continues to integrate these advances to remain at the forefront of innovation.

Emerging trends in draft angle analysis include:

- Integration of artificial intelligence to automatically recommend optimizations

- Simulation of material behavior during demolding

- Multi-criteria manufacturability analysis (draft angle, thickness, cooling)

- Seamless integration into PLM ecosystems and production management

For companies wishing to optimize their design and manufacturing processes, adopting a dedicated solution like 3DViewStation represents a strategic investment with rapid and significant returns.

By reconciling technical performance, ease of use, and controlled cost, 3DViewStation democratizes access to professional draft angle analyses, allowing companies of all sizes to improve their competitiveness in a demanding global market.