Realistic rendering of CAD models is no longer a luxury but a necessity in the modern industrial ecosystem. Beyond aesthetics, this technology radically transforms the way companies communicate, market, and develop their products. According to a recent study, presentations including realistic renderings increase the conversion rate by 40% compared to traditional wireframe representations. This evolution is driven by constant innovations in rendering algorithms and the increasing accessibility of technologies once reserved for specialized studios.

Faced with the diversity of CAD formats and the technical complexity inherent in the rendering process, professionals are looking for solutions that combine precision, simplicity, and performance. The challenge is to quickly transform complex technical models into photorealistic visualizations without compromising the fidelity to the original data.

Table of contents

- Fundamentals of realistic rendering for CAD models

- Advanced techniques to optimize CAD rendering

- Practical applications of realistic rendering by sector

- SimLab Composer: optimal solution for CAD rendering

- Optimal workflow with SimLab Composer

- Comparative study and ROI

Fundamentals of realistic rendering for CAD models

3D realistic rendering represents the transformation of a technical model into a visual representation faithful to reality. Unlike CAD modeling, which focuses on dimensional accuracy and functional properties, rendering aims to simulate the interaction of light with materials to create a convincing visual experience.

The fundamental distinction between these two worlds lies in their objectives: CAD prioritizes technical accuracy while rendering prioritizes perceived appearance. This duality explains why direct export of a CAD model to traditional rendering software often produces disappointing results without appropriate intermediate processing.

The technological evolution of rendering has gone through three major phases:

- Conventional CPU rendering: sequential calculations, extended processing times

- Accelerated GPU rendering: parallelization of calculations, performance multiplied by 50-100

- Intelligent hybrid rendering: dynamic distribution of tasks between CPU and GPU according to their nature

Format interoperability constitutes the cornerstone of an efficient rendering process. A CAD model must retain its essential characteristics (hierarchy, metadata, material attributes) when converted to formats adapted for rendering. This transition without data loss represents a considerable technical challenge that few solutions perfectly master.

On the business side, the impact of realistic rendering manifests at several levels:

| Business Area | Measured Impact |

|---|---|

| Marketing communication | 35% increase in engagement rate |

| Design validation | 40% reduction in physical iterations |

| Sales presentation | 28% improvement in conversion rate |

| Technical training | 45% acceleration in learning cycles |

Advanced techniques to optimize CAD rendering

The transformation of a CAD model into realistic rendering relies on several sophisticated techniques whose mastery determines the quality of the final result. Among these, texture baking occupies a prominent place.

Texture baking consists of pre-calculating surface information (color, roughness, reflectivity) to store them in 2D maps. This technique considerably optimizes performance by replacing complex calculations with simple data retrieval. For a complete automobile model, this approach can reduce rendering time from several hours to a few minutes while preserving comparable visual quality.

In the same spirit, light baking pre-calculates the global illumination and shadows of a scene. This technique:

- Captures complex light interactions such as indirect bounces

- Maintains the illusion of depth and volume even on mobile devices

- Allows for smooth visualization on modest hardware configurations

- Reduces real-time calculation load by up to 95%

The balance between visual quality and performance represents a permanent challenge for CAD rendering solutions. Modern approaches adopt adaptive strategies that dynamically adjust texture resolution, lighting calculation precision, and geometric complexity according to the visualization context.

Progressive rendering constitutes a particularly relevant innovation for professionals. This technique instantly displays a low-resolution version that progressively refines, allowing rapid identification of problems without waiting for the complete process to finish. On complex projects, this approach can save several cumulative hours of work.

The use of physically based materials (PBR - Physically Based Rendering) represents the current state of the art. These materials precisely simulate the behavior of light on different surfaces using measurable parameters such as:

| PBR Parameter | Visual Impact |

|---|---|

| Albedo (base color) | Perceived hue independent of lighting |

| Metallicity | Separation between metallic and non-metallic surfaces |

| Roughness | Sharpness of reflections and polished/matte appearance |

| Normal | Surface details without additional geometry |

| Ambient occlusion | Soft shadows in crevices and junctions |

Practical applications of realistic rendering by sector

Architectural visualization represents one of the areas where realistic rendering of CAD models has revolutionized professional practices. Architects can now present unbuilt buildings in their environmental context, with a level of fidelity allowing clients to completely project themselves into the space. This approach significantly reduces uncertainties and accelerates the decision-making process.

In the field of product engineering, virtual prototyping based on realistic renderings allows for considerable resource savings. A European automobile manufacturer recently reduced its physical iterations by 70% by systematically integrating design reviews based on photorealistic renderings. This approach allows early identification of aesthetic or ergonomic problems without incurring manufacturing costs.

Technical marketing particularly benefits from realistic rendering for:

- Creating interactive catalogs presenting all variations of a product

- Producing visual materials even before manufacturing the final product

- Illustrating complex functionalities through animated exploded views

- Developing 3D configurators allowing customers to customize their products

The technical training and documentation sector exploits realistic rendering to improve knowledge assimilation. Studies demonstrate a 35% increase in information retention when procedures are illustrated by interactive 3D renderings rather than traditional diagrams.

Virtual reality (VR) represents the natural extension of realistic rendering by adding immersion to visualization. VR applications based on CAD models allow:

| VR Application | Business Benefit |

|---|---|

| Collaborative design review | 60% reduction in business travel |

| Immersive technical training | 45% decrease in learning time |

| Maintenance simulation | 87% anticipation of accessibility issues |

| Immersive client presentation | 53% increase in engagement rate |

SimLab Composer: optimal solution for CAD rendering

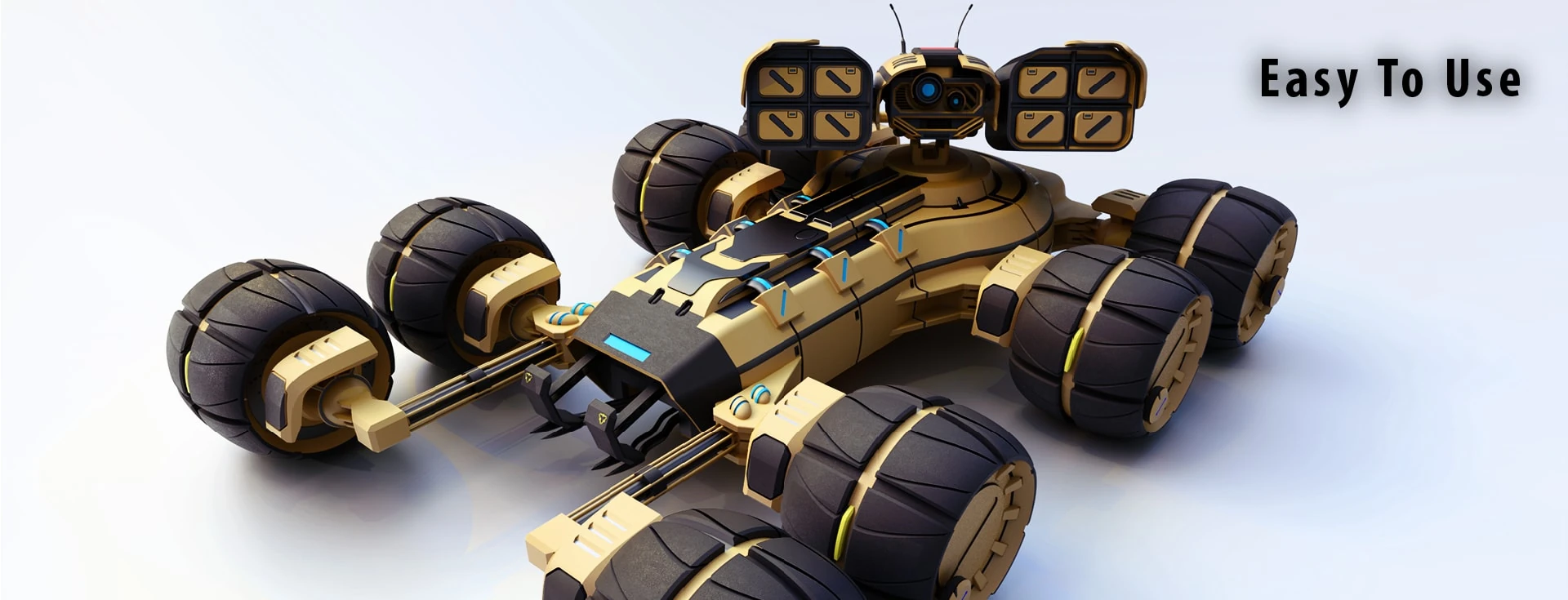

In the complex ecosystem of CAD rendering solutions, SimLab Composer distinguishes itself by an approach centered on the balance between ease of use and functional power. This solution positions itself as the ideal bridge between the technical world of CAD and the visual requirements of realistic rendering.

The software architecture of SimLab Composer is based on three fundamental technological pillars:

- Intelligent import engine preserving hierarchy and metadata of models

- Hybrid rendering system optimally exploiting CPU and GPU

- Progressive processing pipeline allowing editing during rendering

The intuitive user interface represents one of the major assets of this solution. Unlike traditional software that requires weeks of learning, SimLab Composer adopts a drag-and-drop approach that allows even non-specialists to produce professional quality renderings after only a few hours of familiarization.

Format compatibility constitutes a decisive competitive advantage. With more than 25 import formats (including CATIA, SOLIDWORKS, Inventor, Rhino, STEP, IGES) and 15 export formats (including 3D PDF, GLTF, FBX, USDZ), SimLab Composer eliminates interoperability obstacles that typically slow down rendering workflows.

Among the differentiating features, we can cite:

| Feature | Practical Advantage |

|---|---|

| Real-time progressive rendering | Instant adjustments without waiting for calculation to finish |

| 360° Grid System | Creation of multiple interconnected panoramic views |

| Integrated texture baking | Automatic optimization for visualization on mobile devices |

| PBR material libraries | Instant application of physically realistic materials |

| Sequence animation | Simple creation of technical animations without specialized knowledge |

Optimal workflow with SimLab Composer

The process of creating a realistic rendering with SimLab Composer breaks down into three main steps, each optimized to maximize efficiency and minimize the learning curve.

Model import constitutes the entry point of the workflow. This phase is distinguished by:

- A direct drag & drop system from the file explorer

- Automatic preservation of assembly hierarchy

- Maintenance of metadata and technical attributes

- Intelligent detection of materials defined in the CAD model

- Silent optimization of complex geometries for rendering

Scene preparation represents the step where creative vision takes shape. SimLab Composer stands out with tools specifically designed to accelerate this often time-consuming phase:

The integrated library of more than 1000 physically realistic materials allows for instantly applying metallic, plastic, ceramic, or organic finishes. These materials are preconfigured with optimal PBR parameters that guarantee a convincing rendering without complex adjustments.

The environmental lighting system based on HDR (High Dynamic Range) images reproduces real lighting conditions in a few clicks. This approach considerably simplifies lighting, which traditionally represents the most technical aspect of 3D rendering.

The rendering and finalization phase benefits from significant technological innovations:

| Technology | Operational Benefit |

|---|---|

| Progressive rendering | Immediate visualization with continuous refinement |

| Automated texture baking | Optimization for performance on mobile devices |

| Adaptive rendering engine | Automatic quality/performance balancing |

| Contextual export presets | Optimized settings according to destination (web, print, VR) |

Export and sharing options also distinguish SimLab Composer from traditional solutions. The integrated cloud sharing system (20GB included) allows instant synchronization of renderings across different devices and frictionless sharing of 3D experiences without technical friction.

The complete ecosystem also includes SimLab VR Viewer, a free application allowing recipients to visualize renderings on various platforms (Windows, macOS, iOS, Android, Oculus, Vive, Pico VR) without additional investment.

In practice, this optimized workflow allows for drastically reducing production times:

- CAD model import: 3 minutes (versus 15-30 minutes with traditional solutions)

- Scene preparation: 3 minutes (versus 30-60 minutes usually)

- Rendering and finalization: 1 minute (versus 15-120 minutes depending on complexity)

Comparative study and ROI

Comparative analysis of CAD rendering methods reveals significant gaps in terms of operational efficiency. A study conducted among 150 industrial companies shows that adopting an integrated solution like SimLab Composer reduces the total production time of equivalent quality rendering by 78% on average compared to traditional workflows.

This optimization breaks down as follows:

| Process Step | Traditional Approach | SimLab Approach | Efficiency Gain |

|---|---|---|---|

| Model preparation | 45-120 minutes | 3-5 minutes | 95% |

| Material configuration | 30-90 minutes | 2-8 minutes | 89% |

| Lighting setup | 20-60 minutes | 1-3 minutes | 94% |

| Calculation time | 10-240 minutes | 1-15 minutes | 87% |

| Iterations and adjustments | 3-8 cycles | 1-2 cycles | 75% |

Return on investment analysis demonstrates that adopting an optimized solution like SimLab Composer becomes profitable after only 2 to 3 months of use for a company producing 5 renderings per month. This quick payback is explained by the combination of several economic factors:

- Reduction of specialized work hours (design/graphics)

- Decrease in client iterations thanks to early validation

- Elimination of needs for specific hardware dedicated to rendering

- Reduction of training costs (3 days vs 3 weeks)

- Internal production capacity without specialized outsourcing

User experience feedback confirms these benefits. A French engineering office specializing in industrial equipment testifies: "We reduced our client rendering delivery time from 5 days to less than 24 hours, while improving perceived quality. This acceleration has allowed us to increase our business volume by 22% without additional recruitment."

Future trends in CAD rendering are moving towards even deeper integration with immersive technologies (VR/AR) and artificial intelligence. Solutions like SimLab Composer anticipate this evolution by developing VR training functionalities and automatic scene optimization that prefigure tomorrow's standards.

Prospective analysis indicates that the gap between integrated solutions and traditional approaches will continue to widen, making early adoption of optimized tools even more strategic for companies concerned about their technical and commercial competitiveness.

Conclusion

Realistic rendering of CAD models now represents a strategic lever for technical companies, transforming the way they communicate, market, and develop their products. The evolution of rendering technologies has considerably reduced the technical and financial barriers that once limited access to these quality visualizations.

The benefits of an optimized rendering workflow manifest at several levels:

- Significant reduction in product development cycles

- Improvement of internal and external technical communication

- Ability to visualize and validate concepts before production

- Creation of immersive experiences for training and marketing

- Democratization of advanced visualization tools in the company

SimLab Composer positions itself as the ideal solution for companies wishing to integrate realistic rendering into their technical ecosystem without excessive complexity. Its approach centered on operational efficiency and accessibility to non-specialists precisely addresses the current challenges of technical and marketing departments.

Faced with accelerated digital transformation, the integration of tools like SimLab Composer becomes a factor of competitive differentiation. Companies that adopt these optimized technologies gain not only in internal efficiency but also in the ability to communicate their added value in a more convincing and immersive way.

To remain competitive in an environment where visual experience takes on increasing importance, technical organizations must reevaluate their CAD rendering processes and consider integrated solutions as a strategic investment rather than a simple software tool.