Navigating the complexities of CAD collaboration and manufacturing often feels like a high-stakes chess game. From maintaining robust models to reducing engineering errors, businesses are fraught with challenges that could potentially cost a fortune if not addressed promptly. Recent discussions with ITI partners and industry professionals confirm that while these topics are undeniably crucial, they are often sidelined due to budget constraints and a lack of expertise. What if we told you that ignoring these could lead to far graver repercussions than the cost of dealing with them? Dive in to unearth effective solutions for overcoming these hurdles and why making an early investment could save you big in the long run.

At a recent conference with our ITI partner, we interviewed several managers and engineers asking if any of the following topics related to CAD issues are relevant to their company:

- Maintaining robust CAD models throughout the product lifecycle

- Reducing the cost of engineering errors and escapes due to 3D data issues

- Rapidly identifying changes in new revisions of customer CAD models

- Accurately translating data for collaboration and manufacturing

- Reducing model rework and lead times for advanced simulation

- Establishing a robust and validated long term archival system

Almost all agreed that one or all of them were, indeed, important factors. However, they went on to say that such issues are often perceived by the budget holders and project leaders as an overhead or annoyance and consequently are not properly addressed due to lack of budget or specific expertise.

From our experience in CAD collaboration and CAD migration, we note that the risks and the final cost of not addressing these six issues can far outweigh the investments needed to address them..

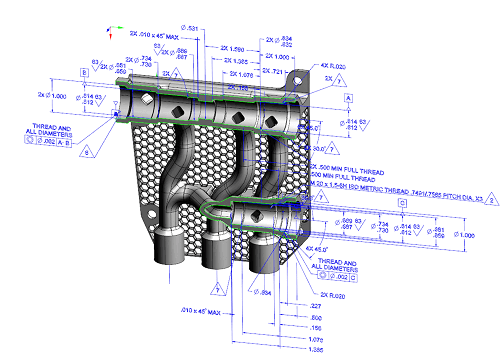

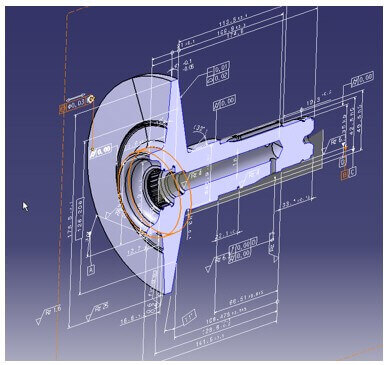

Things are getting even more critical with the wider adoption of Model-Based Engineering (MBE) across industry, where 3D models and their associated 2D drawings are replaced by 3D models containing all necessary 3D product manufacturing information (PMI). The image below shows the interest of the MBE, because when the 3D model is modified, annotations and 3D PMI are also automatically updated in a single file that can be shared throughout the manufacturing supply chain.

MBD part with 3D annotations and PMI

However, a good example of a potential interoperability and collaboration issues is when a supplier receives a new MBE revision from an OEM. It no longer comes with a 2D drawing showing all the modifications. How does the supplier quickly and accurately identify changes and disseminate information to the project team (some of whom will not have access or knowledge of CAD system) so that they can assess the impact of the changes on design, tooling, and project timelines and the ability deliver to the customer?

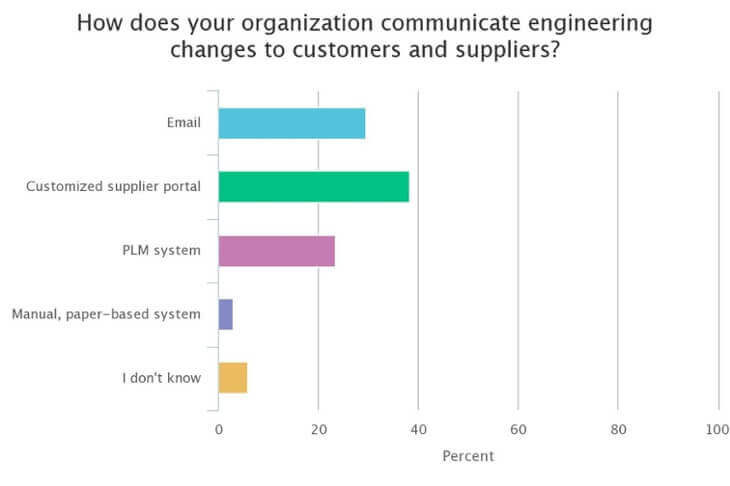

Opening old and new revisions of CAD models side-by-side on a CAD workstation and manually inspecting them to discover model revision changes is time consuming, expensive and above all error prone, which means it is simply not a reasonable option. In our recent MBE web conference, we discovered that nearly 30% of participants still use email to communicate changes. You can easily understand, or have likely experienced yourself, the potential pitfalls related to communicating engineering changes via email.

Poll: Out of 50 engineering respondents, 30% were still using email to communicate changes

At CAD Interop we face such challenges on a daily basis, working with large and international industrial groups, where we have deployed appropriate solutions, whether it be for data migration, MBE model comparison and validation, or the integration of CAD and advanced simulation and manufacturing processes.

If you are faced with any of the six challenges mentioned above, we suggest you explore the proposed solutions that can be put in place to mitigate your potential exposure. A relatively low investment at an early stage, before problems arise, could reap rewards several times over in the future.