Some organizations use the term MBD to represent Model-Based Design and the term MBE to represent Model-Based Engineering. As is often the case with new technologies, different groups develop different terms with similar or overlapping meanings. In our case, we will use the terms MBD for Model-Based Definition and MBE for Model-Based Enterprise.

Why MBD? Why MBE?

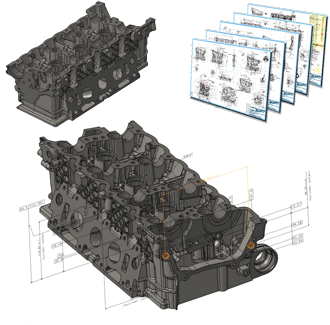

The MBD approach is the next revolution in the CAD / CAM / CAE domain, where annotated 3D models and technical data packages (TDP 3D) are used as a single source for all design information, eliminating the use of 2D drawings.

When an MBD approach is implemented at the beginning of a product's lifecycle and reused throughout the company and its supplier chain, it enables rapid, homogeneous and cost-effective development and deployment of product from conception to disposal. This environment is called Model-Based Enterprise (MBE). MBE is the environment in which MBD represents the product definition or design authority. Switching or migration from 2D drawings to a 3D model with annotations is not sufficient. To justify the benefits of the MBD, an MBE environment must be optimized to share the 3D data set throughout the enterprise and the supplier chain.

An optimized and efficient 3D product lifecycle process, that satisfied the needs of all users, generates a lean environment with less waste. The error rates and rework are reduced, as is labor in the data and document creation process. The cost for printing and maintaining the paper archive is also considerably reduced.

Considerations for Implementing MBD

Many things need to be considered by a enterprise that is considering migrating from a 2D / 3D environment to a 3D MBD environment. Key areas such as legacy data migration and MBD data reuse in the supply chain are often ignored but critical to a successful MBD implementation.

The development of new standards and processes for the creation of annotation in 3D models is a key factor in the MBD approach. Technical data packages must be in a format that is compatible with all CAD systems and all use of the data set. For a model to be the single source for a part, it must be able to be appropriate by the various partners in the chain, regardless of the CAD formats used.

Ensuring quality and original design intent in the model and TDP is also critical. For MBD to trully be faster and more efficient, all users sharing the model must receive the same information. This allows for collaboration without having to ask questions and without risk of downstream manufacturing issues.

CAD Interop has a large range of interoperability solutions that can be deployed to identify and resolve these issues and enable you to implement a successful MBD environment.