ITI is participating in a new Digital Manufacturing and Design Innovation Institute (DMDII) project, a UI LABS collaboration. The “Supply Chain MBE/TDP Improvement” project aims to push Model Based Enterprise (MBE) technologies forward by streamlining the design stage of the manufacturing process.

DMDII has issued a contract research award to a group of partners. ITI is working with the project’s lead organization, Rolls Royce, along with a team of industry organizations including 3rd Dimension, Anark Corporation, Lockheed Martin, Microsoft, and Purdue University, toward the goal of using the intelligent 3D models and accompanying information, the Technical Data Package (TDP), to improve usability and reliability of product data shared across the supply chain.

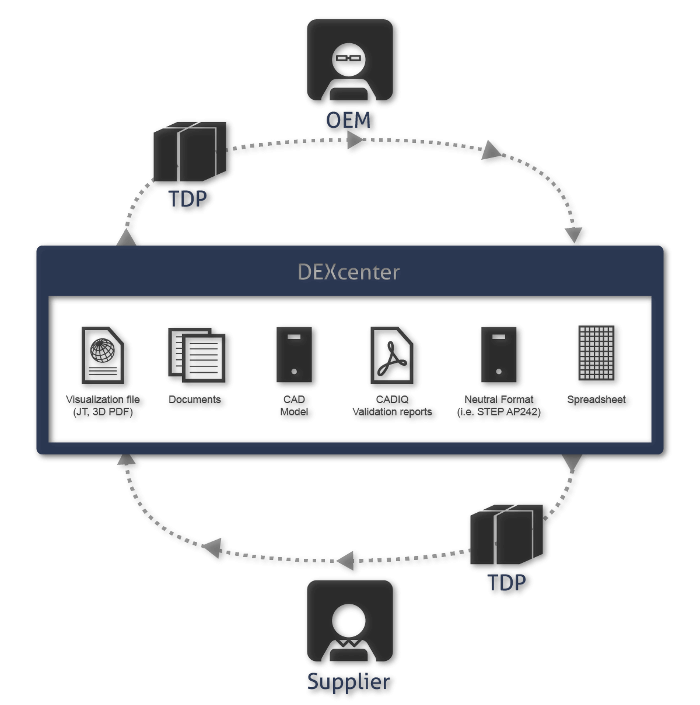

Technical Data Package Automation in a MBE with DEXcenter

Model Based Definition (MBD) is the next revolution in CAD/CAM/CAE, where annotated 3D models and 3D TDPs are used as the single source for all design information, eliminating the need for 2D Drawings. When MBD is implemented at the beginning of the product lifecycle and re-used throughout an enterprise and its supply chain, it enables rapid, seamless and affordable development and deployment of products from concept to disposal. This environment is referred to as a Model Based Enterprise (MBE).

Achieving MBE requires adopting new rapidly evolving technology. The goal of the DMDII project is to demonstrate how various technology solutions can be utilized together effectively. With MBD models including more complete information, securing the Intellectual Property in these models through the supply chain is more important than ever.

ITI’s contributions to the program include the CADIQ and DEXcenter solutions. CADIQ is the leading CAD model quality and validation solution. DEXcenter provides collaboration capabilities with managed secure file transfer and CAD process automation for multi-CAD and MBE scenarios. DEXcenter can be integrated with PLM or other enterprise applications.

“In 2010 ITI participated in the Customer Supplier Interoperability (CSI) project with the AFRL and DoD, which created new technologies to facilitate MBD”, stated John Gray, ITI DEXcenter Program Manager. “This DMDII project builds upon the CSI technology along with industry advances. The DMDII project shows the MBE TDP technology in process, from the OEM clear through to the supplier.”

DEXcenter provides an overall automation framework in which to utilize the new technology, for functions such as:

- Evaluating completeness of MBD models

- Translating MBD models into compatible derivative formats, such as STEP, JT and 3D PDF

- Validating derivative formats using CADIQ

- Documenting Engineering Changes in MBD models

- Accumulating relevant MBD information into a TDP and then securely distributing it through the supply chain

“We did MBD in CSI and now we are doing MBE with DMDII,” stated Tom Gregory, ITI CEO. “ITI is committed to providing leadership in the emerging MBE effort. It is a critical initiative being adopted throughout industry, and we are pleased to be working with our partners to offer viable and reliable solutions to help drive broader adoption of MBE.”