In the world of modern engineering, numerical simulation constitutes an essential pillar of product development. However, a major obstacle persists: the preparation of CAD models. A recent study reveals that engineers spend up to 70% of their time preparing geometries before even launching their analyses. Volume extraction represents one of the most critical and technical steps of this process, capable of radically transforming the accuracy of results and the efficiency of simulation workflows.

Table of contents

- Current challenges in CAD preparation for simulation

- Understanding volume and cavity extraction

- Advanced volume extraction methodologies

- Impact on simulation quality

- Technological solutions for volume extraction

- CADfix DX: advanced solution for volume extraction

- Practical implementation of volume extraction

- Future perspectives and trends

Current challenges in CAD preparation for simulation

The preparation of CAD models for numerical simulation represents a major technical challenge for industrial companies. Designers typically create models optimized for manufacturing, incorporating numerous details that, while essential for production, can be problematic for simulation.

In an industrial context where product complexity continues to increase, CAD models are becoming increasingly sophisticated. This sophistication creates specific challenges during preparation for simulation:

- Excessive presence of geometric details not relevant for analysis

- Incompatibilities between CAD data formats and formats required by solvers

- Geometries with imperfections (missing faces, incorrect intersections)

- Complex multi-body structures requiring specific decomposition

- Variability of requirements depending on the type of simulation (structural, thermal, fluid)

Traditional approaches to CAD model preparation have significant limitations. The manual method, while precise, is extremely time-consuming and prone to human error. According to a study in the aerospace industry, up to 80% of preparation time for simulation is devoted to manual correction of geometries and extraction of relevant volumes.

These inefficiencies directly translate into prolonged development cycles and increased costs. Unresolved geometric imperfections can also compromise the accuracy of results, leading to suboptimal designs or, in the worst case, product failures after manufacturing.

| Type of imperfection | Impact on simulation | Potential consequence |

|---|---|---|

| Non-watertight geometry | Failure of volumetric meshing | Impossibility to simulate |

| Superfluous details | Excessively fine mesh | Explosive calculation times |

| Duplicate entities | Singularities in the mesh | Incorrect results |

| Non-extracted volumes | Analysis on inappropriate geometry | Unvalidated design |

Understanding volume and cavity extraction

Volume extraction constitutes a fundamental operation in the process of preparing CAD models for numerical simulation. This technique allows isolating the three-dimensional spaces relevant for analysis, whether it's the volume occupied by a solid material or a fluid volume contained in a structure.

From a technical perspective, volume extraction is defined as the process of identifying and isolating regions of interest within a complex CAD model. Unlike the traditional design approach that focuses on the boundaries and surfaces of components, volume extraction primarily focuses on the three-dimensional space defined by these boundaries.

Several types of volume extraction can be distinguished according to the specific needs of the simulation:

- Solid volume extraction: isolating material for structural, thermal, or vibratory analyses

- Cavity extraction: isolating internal void space for fluid flow analyses (CFD)

- Envelope volume extraction: creating an encompassing volume for external aerodynamic or acoustic analyses

- Multi-volume extraction: identifying and separating different domains for multi-physics analyses

These extraction techniques find essential applications in various industrial sectors:

- Aerospace: Flow analysis in ventilation ducts or tanks

- Automotive: Thermal simulation of engine blocks or acoustic analysis of the passenger compartment

- Medical: Modeling of blood flow in cardiovascular devices

- Electronics: Thermal analysis of housings with air circulation

- Energy: Optimization of geometries for turbomachines and heat exchangers

To ensure effective volume extraction, several quality criteria must be respected:

- Geometric watertightness of the extracted volume

- Precision of interfaces between adjacent volumes

- Appropriate suppression of irrelevant features

- Preservation of critical details for the physics being studied

- Compliance with the specific requirements of the target solver

Respecting these criteria ensures that the extracted volume faithfully represents the physical reality of the system being studied while allowing for efficient numerical analysis.

Advanced volume extraction methodologies

Given the increasing complexity of CAD models, various volume extraction methodologies have emerged to meet the specific needs of numerical simulation. These approaches are distinguished by their degree of automation, robustness, and ability to handle complex geometries.

Automated versus semi-automated approaches

Volume extraction methods are mainly divided into two categories:

| Approach | Advantages | Limitations | Ideal applications |

|---|---|---|---|

| Automated | - Execution speed - Reproducibility - Suitable for batch workflows | - Robustness limited to standard cases - Complex initial parameterization - Difficulties with atypical geometries | Standardized models, repetitive processes, large assemblies |

| Semi-automated | - User control over critical areas - Adaptability to complex cases - More reliable results | - Human intervention required - Increased processing time - Variability depending on the operator | Complex geometries, critical models, innovative prototypes |

Advanced volume extraction tools typically combine both approaches, offering automated workflows with the possibility of manual intervention at critical steps.

Feature recognition and extraction techniques

Automatic feature recognition constitutes a major advancement for volume extraction. These techniques allow intelligent identification of specific geometric elements (holes, pockets, ribs, fillets) even in the absence of construction history. Modern algorithms employ various strategies:

- Template recognition: identification by comparison with predefined geometric patterns

- Topological recognition: analysis of relationships between geometric entities

- Propagation recognition: progressive extension from initial elements

- Learning-based recognition: use of artificial intelligence for identification

These methods allow not only to identify features but also to prioritize them according to their relevance for simulation, thus facilitating decision-making regarding their preservation or suppression.

Parameterization methods for complex zones

Parameterization of complex zones represents a major challenge in volume extraction. These zones, characterized by non-standard geometries or multiple interfaces, require specific approaches:

- Block decomposition: subdivision into simpler geometric regions

- Adaptive parameterization: local adjustment of parameters according to complexity

- Medial axis methods: use of the medial axis to guide decomposition

- Conformal parameterization: maintenance of geometric relationships at interfaces

These techniques allow transforming complex geometries into representations more suitable for numerical simulation, while preserving essential characteristics.

Splitting technologies for mesh optimization

Geometric splitting constitutes an essential step to prepare volumes adapted for meshing. Recent technologies include:

- Quadratic splitting: division of surfaces into quasi-rectangular elements to facilitate hexahedral meshing

- Medial partitioning: use of the medial axis to decompose volumes

- Subdomain decomposition: creation of homogeneous regions for optimized meshing

- Adaptive subdivision: local refinement based on geometric or physical characteristics

These methods allow obtaining volumes whose structure facilitates the generation of high-quality meshes, essential for the accuracy of numerical simulations.

Impact on simulation quality

Volume extraction directly influences the quality and reliability of numerical simulations. This preparatory step determines not only the accuracy of results but also the overall efficiency of the simulation process.

Improvement in result accuracy

Optimal volume extraction significantly improves the accuracy of numerical simulations. By precisely isolating domains of interest and eliminating superfluous geometries, this technique ensures that the analysis focuses on relevant physical phenomena. Concrete benefits include:

- More faithful representation of boundary conditions

- Better capture of gradients in critical regions

- Reduction of numerical artifacts related to inappropriate geometries

- More stable convergence of numerical solvers

Comparative studies in the aeronautical industry demonstrate that properly extracted volumes can improve the accuracy of results by 15% to 30% compared to simplified approaches.

Optimization of calculation times

Volume extraction significantly contributes to optimizing calculation times in numerical simulation. By reducing geometric complexity to only necessary elements, this technique allows:

- A reduction in the number of mesh elements (up to 70% in some cases)

- A proportional decrease in required computing resources

- Faster design iterations

- More complete exploration of the parameter space

This optimization translates into significant acceleration of the product development cycle, allowing companies to reduce their time to market while maintaining high design quality.

Reduction of convergence errors

Convergence problems represent a major challenge in numerical simulation. Inappropriate volume extraction can lead to:

- Numerical oscillations at poorly defined interfaces

- Mathematical singularities in the mesh

- Instabilities in solution schemes

- Complete divergences preventing results from being obtained

Conversely, methodical volume extraction considerably reduces these problems. Industrial statistics show that simulation failure rates can be reduced by more than 60% through advanced extraction techniques.

Concrete cases of performance improvement

The impact of volume extraction on simulation performance is evident in many industrial sectors:

| Sector | Application | Observed benefits |

|---|---|---|

| Automotive | Thermal analysis of engine components | - 45% reduction in calculation time - 22% improvement in accuracy - Reduction of design iterations from 3 to 1 |

| Medical | Flow simulation in implantable devices | - 35% improved prediction of stagnation zones - 70% reduced preparation time - Accelerated prototype validation |

| Aerospace | Structural analysis of lightweight components | - Precise identification of stress concentrations - Additional weight reduction of 8% - Significant material savings |

Technological solutions for volume extraction

The market for volume extraction technological solutions has evolved considerably in recent years, offering a range of tools with diverse capabilities. A thorough understanding of these solutions allows organizations to select the one that best matches their specific needs.

Overview of available solutions

The ecosystem of volume extraction solutions for numerical simulation comprises several categories:

- Modules integrated into CAD platforms: limited extraction functionalities included in design systems

- Specialized simulation preparation solutions: dedicated tools offering advanced extraction and preparation capabilities

- Complementary modules to simulation software: extensions enhancing the geometric preparation capabilities of solvers

- Integrated design-simulation platforms: unified environments facilitating the transition between design and analysis

Each of these approaches presents its own advantages and limitations in terms of functionality, interoperability, and integration into existing workflows.

Selection criteria for an appropriate solution

Selecting an appropriate volume extraction solution relies on several essential criteria:

| Criterion | Description | Key questions to ask |

|---|---|---|

| Format compatibility | Ability to process CAD formats used in the organization | Does the solution support all your native formats? What is the quality of conversions? |

| Robustness | Reliability with complex or imperfect geometries | How does the solution handle difficult cases? What is the success rate on complex models? |

| Automation | Level of automation of extraction processes | Which tasks can be automated? Are custom scripts possible? |

| Workflow integration | Ease of integration into existing processes | Does the solution interface with your CAD and CAE tools? Are APIs available? |

| Performance | Efficiency in processing large assemblies | What are the size limits of models? Is parallel processing supported? |

| Support and training | Availability of technical assistance and learning resources | What is the quality of support? Are specific training courses offered? |

These criteria should be weighted according to the specific needs, industrial context, and technical constraints of each organization.

Essential functionalities for effective extraction

A high-performance volume extraction solution must integrate several essential functionalities:

- Automatic feature recognition: intelligent identification of geometric elements such as holes, pockets, and fillets

- Selective suppression: ability to eliminate certain features while preserving the integrity of the model

- Cavity extraction: creation of volumes representing the void space inside an assembly

- Domain decomposition: intelligent subdivision of volumes to facilitate structured meshing

- Simplification tools: reduction of geometric complexity while preserving essential characteristics

- Repair tools: correction of geometric imperfections affecting volume extraction

- Verification and validation: quality control of extracted volumes before export to the solver

The harmonious integration of these functionalities into an intuitive interface constitutes a determining factor of the overall effectiveness of the solution.

Integration into existing simulation workflows

The efficient integration of a volume extraction solution into existing workflows represents a major challenge for organizations. Several aspects must be considered:

- Bidirectional interoperability: smooth data exchange between CAD systems, preparation tools, and solvers

- Workflow automation: ability to create automated processes for recurring cases

- Modification traceability: documentation of transformations applied to the original model

- Revision management: ability to effectively propagate design modifications

- Multi-user collaboration: support for collaborative work between design and simulation teams

Successful integration results in a significant reduction in transfer times between different stages of the process, allowing analysts to focus on high-value aspects of their mission.

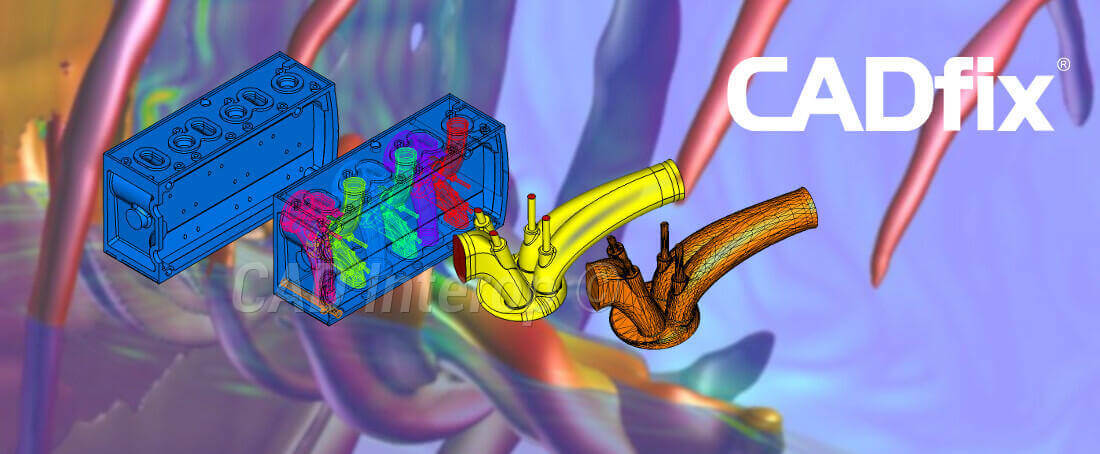

CADfix DX: advanced solution for volume extraction

In the landscape of model preparation solutions for numerical simulation, CADfix DX stands out as cutting-edge technology specifically designed to address the complex challenges of volume extraction.

General presentation of the technology

CADfix DX represents an advanced CAD model preparation solution specially developed to optimize numerical simulation workflows. This technology effectively transforms complex CAD geometries into models perfectly adapted to the specific requirements of numerical analyses.

Founded on more than 25 years of expertise in resolving data exchange and reuse issues, CADfix DX offers a comprehensive approach integrating:

- Extended compatibility with major native and neutral CAD formats

- Automatic and interactive geometric repair tools

- Advanced volume and cavity extraction functionalities

- Robust simplification and geometric optimization capabilities

- An intuitive interface guiding the user through the process steps

This unique combination allows engineers to effectively eliminate geometric imperfections that slow down or prevent analysis processes, thus enabling them to focus on interpreting results rather than preparing data.

Specific capabilities for volume and cavity extraction

CADfix DX particularly excels in volume extraction thanks to several specialized functionalities:

Intelligent feature suppression

The technology integrates sophisticated algorithms for effectively identifying and removing various non-essential features in a CAD model:

- Drillings and borings of different dimensions

- Complex fillets and blends

- Chamfers and other edge treatments

- Small bodies and non-relevant details

- Internal elements with no impact on analysis

A major advantage of CADfix DX lies in its ability to automatically recognize certain features even in the absence of construction history, as in the case of neutral formats (STEP, IGES). For more complex functions, the software offers identification methods by dimension or via semi-automatic selection with tangency propagation.

Advanced cavity extraction

CADfix DX offers specific tools for extracting internal volumes (cavities) essential for fluid flow analyses:

- Automatic identification of enclosed spaces within complex assemblies

- Intelligent management of interfaces between components

- Adapted processing of inlet/outlet zones for boundary condition definition

- Configurable preservation of internal details according to their influence on flow

These capabilities allow rapid generation of precise cavity models directly usable by CFD solvers, thus eliminating many manual steps traditionally necessary.

Automated model processing

CADfix DX integrates several automated technologies that significantly accelerate the preparation process:

Complex zone parameterization

Modern CAD systems often generate geometries that are difficult to process for conventional meshing tools. CADfix DX's complex zone parameterization tool overcomes this limitation by allowing users to parameterize models according to existing geometric boundaries. This approach facilitates the placement of regular-sized meshes beyond difficult surfaces, thus preserving mesh quality.

Optimized quadratic splitting

For complex surfaces requiring high-quality quadrilateral meshing, CADfix DX offers a "Split face into quads" tool that automates the identification of appropriate regions and the division of CAD faces. This functionality enables obtaining regular meshes even on complex geometries, thus ensuring a better numerical representation of the physical model.

Hex-Skin partitioning for hybrid meshing

Hex-Skin partitioning technology represents a significant advancement in model preparation for simulation. This functionality allows:

- Automatically partitioning a model using medial object technology

- Creating an optimized hexahedral mesh layer near surfaces

- Generating an unstructured tetrahedral mesh for the rest of the volume

This hybrid approach avoids the propagation of singularities while allowing appropriate mesh sizing near surfaces, where precision is often crucial for simulation results.

Integration with major simulation solvers

CADfix DX offers seamless integration with the main simulation solvers on the market:

- Structural formats: ANSYS, NASTRAN, ABAQUS, LS-DYNA

- Fluid formats: FLUENT, CFX, OpenFOAM, STAR-CCM+

- Thermal formats: FLITE3D, ICMS, TAITherm

- Generic formats: UNV, CGNS, XDMF

This extended compatibility allows users to maintain continuous workflows between model preparation and analysis, eliminating intermediate conversions that can introduce errors or data loss.

Practical implementation of volume extraction

The effective implementation of volume extraction requires a methodical and systematic approach. This section presents best practices to fully exploit this technology in various industrial contexts.

Step-by-step methodology

A successful volume extraction process typically follows a logical sequence of operations:

- Preliminary evaluation: analysis of the source CAD model to identify problematic features and define extraction needs

- Initial preparation: conversion and repair of geometric data to ensure model integrity

- Targeted simplification: removal of details not relevant for the specific analysis

- Volume extraction: isolation of regions of interest according to the type of analysis (solid or fluid)

- Partitioning: subdivision of the volume into regions suitable for meshing

- Verification: quality control of the extracted volume according to the criteria of the target solver

- Export and documentation: transfer to the simulation system with relevant metadata

This sequence can be adapted according to the complexity of the model and the specific requirements of the analysis to be performed.

Typical use cases and best practices

Several use cases illustrate the practical application of volume extraction in different industrial contexts:

Structural analysis of mechanical components

For finite element analysis of mechanical components, best practices include:

- Preservation of features influencing stress distribution

- Removal of small holes and fillets without significant structural impact

- Preservation of contact zones and interfaces between components

- Decomposition into subdomains to facilitate the application of boundary conditions

Thermal analysis of electronic housings

For thermal simulations of electronic assemblies, the recommended approach includes:

- Detailed modeling of critical thermal interfaces

- Simplification of components with low thermal impact

- Adequate representation of air passages for convection

- Precise extraction of interacting fluid and solid volumes

Flow analysis in hydraulic systems

For CFD simulations of hydraulic components, recommended practices include:

- Precise extraction of cavities representing the fluid domain

- Preservation of features significantly influencing flow

- Careful definition of inlet/outlet zones for boundary conditions

- Adapted parameterization of high-gradient regions

Parameter optimization for different types of simulation

Optimization of extraction parameters varies considerably according to the type of simulation envisaged:

| Simulation type | Critical parameters | Optimization recommendations |

|---|---|---|

| Structural (FEA) | - Simplification tolerance - Minimum feature size - Face merge criteria | - Prioritize preservation of stress concentrators - Preserve sharp edges at structural junctions - Use more conservative parameterization in critical zones |

| Fluid (CFD) | - Precision of inlet/outlet sections - Wall roughness - Boundary layer representation | - Maintain precise section of flow channels - Preserve features influencing turbulence - Optimize transition between zones of different resolution |

| Thermal | - Thermal contact surface - Thin wall thickness - Material continuity | - Ensure precise representation of thermal interfaces - Preserve the geometry of elements with high thermal capacity - Adapt simplification according to material conductivity |

Fine-tuning these parameters often requires an iterative approach, evaluating the impact of different configurations on mesh quality and preliminary results.

Result evaluation and quality control

Systematic evaluation of extracted volumes constitutes an essential step to ensure reliable simulations. A robust quality control process includes:

- Watertightness verification: ensuring the volume has no leaks or discontinuities

- Meshability analysis: evaluating the volume's ability to generate a quality mesh

- Simplification control: verifying that simplification has not altered essential characteristics

- Dimensional validation: confirming that critical dimensions have been preserved

- Interface verification: ensuring compatibility at boundaries between domains

Some organizations establish formal validation processes, including mesh convergence studies and sensitivity analyses to confirm that volume extraction does not introduce significant bias in simulation results.

Future perspectives and trends

The field of volume extraction for numerical simulation is evolving rapidly, driven by technological advances and growing industry requirements. This section explores emerging trends that will shape the future of this discipline.

Technological innovations in volume extraction

Several technological innovations promise to transform volume extraction practices in the near future:

- Advanced geometric representations: emergence of mathematical formalisms allowing more flexible and precise volume definition

- Robust boolean operations: new algorithms improving the reliability of intersection, union, and subtraction operations on complex geometries

- Adaptive parameterization techniques: advanced methods automatically adapting to the local complexity of geometries

- Intelligent compression: multi-resolution representations allowing fluid transitions between different levels of detail

- Semantic extraction: volume identification based on functional significance rather than purely geometric

These advances will enable processing increasingly complex models while reducing the required manual intervention.

Integration with artificial intelligence

Artificial intelligence brings a transformative dimension to volume extraction for numerical simulation:

- Automatic recognition through deep learning: identification of geometric features by convolutional neural networks

- Optimization by intelligent agents: automatic parameterization of extraction processes according to simulation objectives

- Quality prediction: anticipation of potential meshing or simulation problems based on analysis of the extracted volume

- Classification of geometric entities: automatic categorization of features according to their importance for different types of analysis

- Transfer learning: application of knowledge acquired on certain geometries to new classes of problems

These technologies will enable more advanced automation and intelligent adaptation to the specificities of each model and type of analysis.

Increased automation of preparation processes

Automation represents a major trend in the evolution of volume extraction practices:

- Fully automated workflows: complete processing chains requiring minimal human intervention

- Adaptive scripts: automation routines automatically adjusting to the particularities of each model

- Automated validation: integrated quality controls with autonomous correction loops

- Intelligent batch processing: systems capable of efficiently processing sets of models with resource optimization

- Cloud integration: relocating intensive calculations to accelerate processing of large models

This increased automation will allow experts to focus on high-value tasks, such as interpreting results and optimizing designs, rather than manual model preparation.