CADIQ: The Ultimate Tool for CAD Validation and Revision Tracking

In a landscape where precision is paramount, CADIQ stands as a quintessential tool for ensuring the integrity and quality of your CAD models. A vendor-agnostic application, CADIQ shines a spotlight on the intricacies of model-based design (MBD), identifying flaws and discrepancies that could spell trouble for manufacturing, data exchange, and simulation. By harnessing the power of CADIQ, you gain a robust ally in validating critical engineering workflows like change management, version control, and manufacturability.

Here's a snapshot of what CADIQ can do for you:

- Derivative CAD Validation: Spot unacceptable variances between native and derivative models.

- Revision Comparison: Detect unintended or undocumented modifications between model revisions.

- Quality Checking: Pinpoint significant defects in a native model affecting its downstream re-use.

Key Strengths of CADIQ

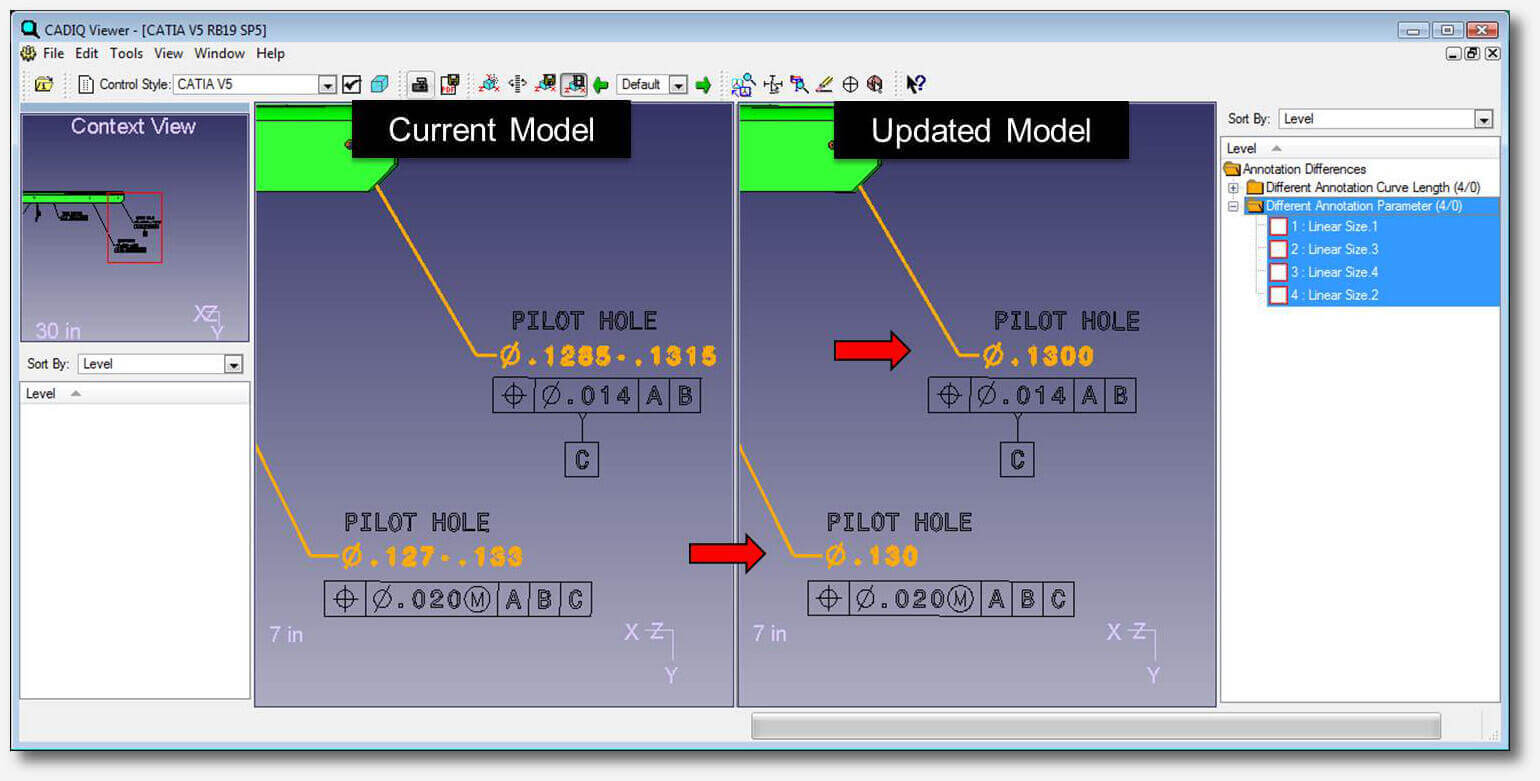

CADIQ doesn't just verify CAD models; it offers a comprehensive analysis of geometry, design features, and product manufacturing information (PMI). The analysis spans across related models to pinpoint any notable differences.

- Comprehensive Analysis: Compares geometry, design features, and PMI between related models.

- Interactive Reports: Generates user-friendly 3D PDF reports for enterprise-wide distribution.

- Long-Term Archival: Aids engineers in the validation of CAD models for long-term archival and retrieval (LOTAR).

From comparing intricate design elements to facilitating clear communication between departments, CADIQ serves as a holistic solution for managing and validating your CAD data.

CADIQ Application in Detail

Now that we've examined CADIQ's overarching functionalities, it's time to delve into its applications in greater depth. Its robust capabilities extend far beyond merely identifying issues; they also assist in managing and resolving them effectively.

A. CADIQ's Application for CAD Model Validation

CADIQ excels in developing processes that identify and rectify issues related to design quality and data interoperability, a cornerstone in enhancing downstream product data re-use.

Let's look at some examples of validation:

- Geometry Issues: Problems that obstruct model re-use in analysis and manufacturing.

- Unrealistic Features: Features requiring modifications during CAE/CAM model re-use, causing a divergence between the master product model and downstream CAx models.

- Unwanted Changes: Changes occurring during processes like translation, migration, or manual re-mastering.

- Undocumented Modifications: Changes between design revisions or within engineering change orders that are not properly documented.

- Complex Parametric Relationships: Changes arising from intricate parametric relationships that are not clearly understood by CAD users.

- Assembly Product Structure: Unforeseen changes to assembly product structure models during import/export processes.

B. CADIQ's Application for Long-Term CAD Data Archival

CADIQ also specializes in long-term data archival, providing capabilities to document quality defects in the design model. This enables users to set realistic expectations for data re-usability.

- Archive Management: CADIQ enables thorough validation, ensuring the quality and shape of the derived forms are equivalent to the master model. If using STEP, validation properties can be added for future validation of archive data format conversions.

C. CADIQ's Application for CAD Data Certification

Data certification is another crucial application of CADIQ. It verifies that the design model is free from quality defects and that its derived forms are equivalent to the master model.

- Quality Assurance: CADIQ offers quality diagnostics that comply with SASIG PDQ criteria.

- Native System Interfaces: Although CADIQ promotes Native System Interfaces, it accommodates scenarios where access to native CAD systems is restricted, especially relevant for smaller suppliers.

D. CADIQ's Application for MBD Model Validation

Finally, let’s discuss CADIQ's role in Model-Based Design (MBD) model validation, which includes engineering, manufacturing, and sustainability aspects.

- MBD Components: An MBD model comprises Structure, Geometry, Annotations like 3D PMI, GD&T, FT&A, Model attributes, and Domain-specific data.

- The Need for MBD Validation: As the model becomes the master, downstream modifications must align with it. The design model should be re-usable in various phases of the product lifecycle.

- Scenarios Requiring MBD Validation: These include engineering changes, legacy data migration, supplier integration, certified data delivery, and long-term archival.

To wrap up, CADIQ's multi-faceted applications make it an indispensable tool for CAD validation. From model comparison to long-term archival, it offers a range of features that fulfill complex needs. This reinforces why CAD Interop’s CADIQ solution is a crucial asset for anyone serious about CAD data management.

Why Choose CADIQ Over Competitors

In a market saturated with CAD validation solutions, CADIQ sets itself apart through distinct features and capabilities. This section elucidates the advantages of CADIQ in comparison to its competition.

- Vendor Neutrality: CADIQ impartially reveals defects in your CAD models, including those introduced by the CAD systems themselves.

- All-in-One Tool: CADIQ offers complete validation for CAD models, from quality verification to model comparison.

- Multi-Format Compatibility: CADIQ validates part and assembly models, including PMI, from all major CAD systems and neutral formats.

- Uniform Configuration: The same configuration per scenario can be used regardless of the CAD format or system being validated.

- Flexible Pricing: A modular solution that adapts to customer needs for a fair price.

- Interactive Display: The tool provides an interactive, side-by-side 3D display for quick comparisons. You can compare up to 4 models simultaneously.

Unraveling the Utility of CADIQ PDF Reports

The generation of 3D PDF reports with CADIQ isn't just an add-on; it's a transformative feature that enhances the value and utility of CAD model validation. Let's explore its attributes in depth.

- Broad Accessibility : The 3D PDF format opens doors to users who might not have specialized knowledge of CADIQ. The models, complete with diagnostic results, become widely shareable, increasing the reach of critical validation data.

- Detailed Diagnostic Reporting : Whether you're focusing on quality validation or side-by-side comparison, CADIQ provides options to publish results in a 3D PDF. The reports offer comprehensive insights into the model's characteristics.

- Automated Report Generation : Efficiency is a watchword here. CADIQ users can auto-generate 3D PDFs either during a controller/analysis session or directly within the CADIQ Viewer, streamlining the process considerably.

- Customizable Views : The CADIQ Viewer allows users to construct custom views that annotate an active session and capture the 3D model, viewpoint, diagnostics, and markers. These views can then be incorporated into the 3D PDF report, providing a tailored perspective.

Clearly, CADIQ's PDF Reports are far more than just another feature. They redefine the standards for CAD validation by offering both depth and accessibility.

References and Customer Case Studies

ITI supported a twelve-month evaluation and testing phase in collaboration with MTU Aero Engines' LOTAR initiative. CADIQ emerged as the preferred solution for the validation of MTU’s NX and STEP data. Its ease of integration, support for LOTAR verification/validation checks, cloud of points capabilities (from NX to STEP), multi-CAD kernel support, and JT file validation were key factors in this selection. Read the case in English.

Additional case studies:

- Ford: Employing CADIQ for six-sigma quality and translation validation. Learn more

- Johnson Gate: A Tier 1 automotive supplier uses CADIQ to ensure model quality. Learn more

- MTU Aero Engines: CADIQ is utilized to verify and validate CAD models for Long-Term Archival and Retention (LOTAR). Learn more

- NAVAIR: Significant cost savings are discovered as NAWCAD explores moving to Model-Based Definition (MBD). Learn more

- And various other clients in the automotive and aerospace sectors.

Through these case studies, we demonstrate our expertise in data interoperability for design and digital simulation. Our partnerships with companies like ITI and our distribution of cutting-edge solutions like CADIQ underline our ability to meet the complex and diverse needs of the industry.

Trainings and Resources: Empowering Users for Success

To harness the full potential of CADIQ, it's crucial to have access to comprehensive training programs and resources. Here's what we offer to ensure that you are fully equipped for optimal software usage.

- Available Resources : CADIQ comes with an arsenal of supportive materials for users to get up to speed quickly.

- PDF Documentation: Detailed guides to assist you in leveraging the software's capabilities.

- Default Configurations: Pre-set settings to help you get started without any hassles.

- Trainings and Consulting Services : We believe that a well-informed user is an empowered one. Our training options aim to make you a CADIQ expert.

- CADIQ Standard Product Training: A two-day on-site program to deepen your understanding of the product.

- CADIQ Quick Start Program: A comprehensive 5-day course to fast-track your proficiency.

- CADIQ Day Pilot Program: Includes 3 days of on-site installation and training, 2 days of remote support, and extended CADIQ software usage for 30/60/90 days.

- Production Deployment Consulting : Tailored to meet your unique needs, this service aims to ensure seamless integration of CADIQ into your existing workflows.

In summary, this detailed exploration has illuminated the robust features of CADIQ, its ease of integration, its superiority over competitors, and the vital training and resources offered to make the user experience more rewarding. From powerful diagnostic capabilities to interactive 3D PDF reports and comprehensive training programs, CADIQ stands out as a comprehensive solution for CAD data validation.

We invite you to take your CAD data validation processes to the next level with CADIQ. Explore its myriad features and advantages to see why it is the optimal choice for your needs. For more information or to get started, feel free to fill out the available forms on this website.