CAD systems

Based on our over 25 years experience, CAD Interop recommends below the most relevant CAD formats to convert your data between major CAD systems. To date, the most common exchange format is the STEP format, the most complete and available for the majority of CAD software. But, when possible, it is preferable to use the geometry kernel of the software (such as Parasolid for NX, SolidWorks or Solid Edge) which will allow to read the geometry without translation. If you want to provide read-only access to your CAD data for users who do not have a viewer or other CAD software, we recommend using the 3D PDF format in its faceted (lighter) version.

| |||||||||||||||||||||||||||||||||||||||||||||||||

(*) recommended neutral file format for 3D geometry interoperability

(1) Only major neutral file formats are listed. Some CAD systems may have some limitations with specific format.

CAD Interop distributes several solutions to view, translate or validate CAD files. Find below the list of our products compatible with major CAD formats.

Table of Contents

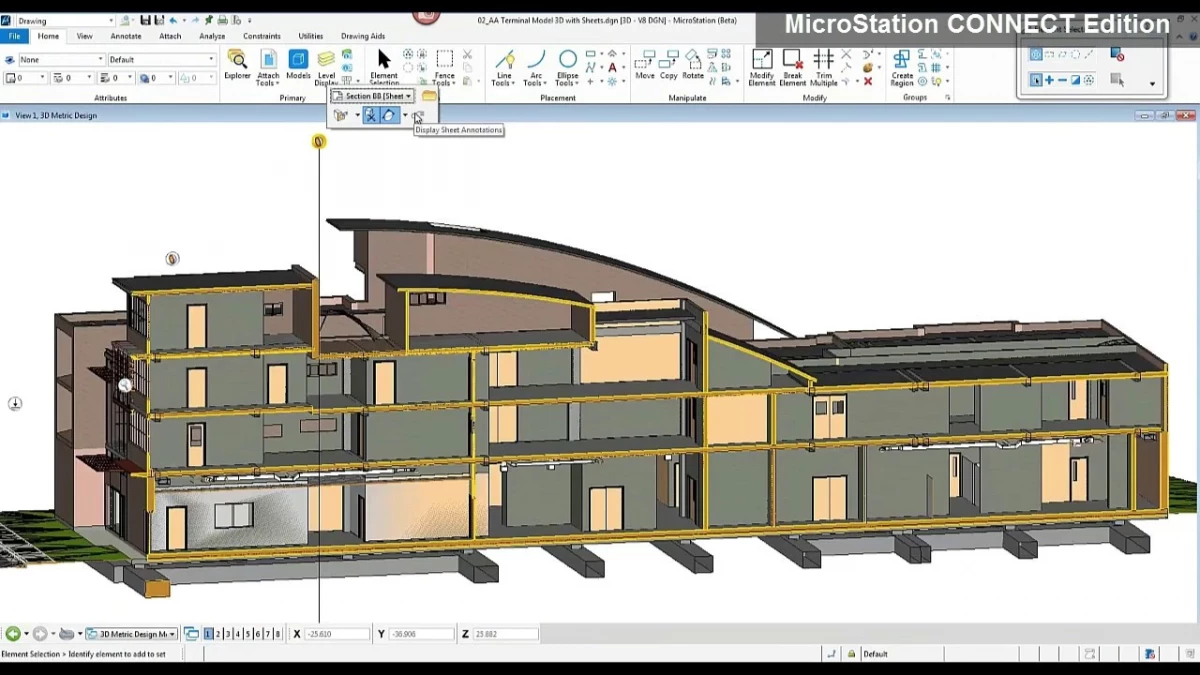

Technical data interoperability represents a major challenge for companies using multiple CAD systems, particularly in engineering, architecture, and construction sectors. MicroStation, developed by Bentley Systems, offers interoperability capabilities enabling seamless data exchange with other CAD platforms. This guide examines MicroStation's interoperability capabilities, its data exchange mechanisms, and complementary solutions to optimize multi-CAD workflows.

In an industrial environment where multi-disciplinary collaboration has become the norm, mastering MicroStation interoperability represents a strategic advantage for technical teams. Challenges related to CAD data exchange directly impact engineering project productivity and the quality of final deliverables.

MicroStation Interoperability Ecosystem

MicroStation distinguishes itself through its flexible approach to CAD interoperability, allowing direct interaction with numerous formats without systematically requiring intermediate conversions. This characteristic facilitates MicroStation integration in heterogeneous environments where multiple CAD systems coexist. The platform offers the possibility to reference, import, visualize, and modify files from various sources while preserving the integrity of technical data.

MicroStation's open architecture promotes fluid data exchange and adapts to the requirements of different phases in engineering project lifecycles. From initial design to manufacturing and long-term archiving, the MicroStation ecosystem enables essential digital continuity for complex projects.

Key Components of the Interoperability Ecosystem

- Integrated multi-format referencing engine

- Bidirectional translation capabilities with metadata preservation

- Support for international exchange standards

- Automatic geometric healing mechanisms

- Integration with PLM and document management systems

Supported Formats and Data Exchange Mechanisms

MicroStation supports a wide range of native formats and exchange standards, facilitating interoperability with various CAD platforms. This flexibility allows companies to maintain efficient workflows even in complex multi-CAD environments.

Native and Proprietary Formats

- DGN - MicroStation's native format with full feature support

- DGN V7/V8 - Compatibility with previous MicroStation versions

- DWG/DXF - Native support for AutoCAD formats via RealDWG 2016

- SKP - Import of SketchUp models

- 3MX - Support for Acute3D models for reality capture

Neutral Exchange Standards

- STEP (AP203, AP214, AP242) - ISO standard for product data exchange

- IFC - Building Information Modeling (BIM) format

- JT - Lightweight format for 3D data visualization and exchange

- 3D PDF - Interactive technical documentation format

- IGES - Historical standard for CAD data exchange

Data Exchange Mechanisms

MicroStation offers four main mechanisms for interacting with external data:

- Referencing - Attaching external files without modifying the original

- Importing - Converting external data to native DGN format

- Exporting - Converting DGN data to other formats

- Direct editing - Modifying certain external formats without prior conversion

MicroStation's Interoperability Advantages

MicroStation's interoperability approach offers several strategic advantages for companies managing complex projects involving multiple CAD formats. These strengths help optimize engineering workflows and reduce risks associated with data conversion.

Key Advantages

- Data translation fidelity - Preservation of geometric characteristics, annotations, and PMI during conversions

- Conversion-free workflows - Ability to work directly with referenced files without mandatory conversion

- Stability with large datasets - Efficient management of complex and voluminous models

- Preserved metadata - Retention of critical technical information during exchanges

- Complete Model-Based Definition (MBD) support - Maintenance of 3D dimensions and tolerances during exchanges

When benchmarking against other CAD solutions, MicroStation demonstrates a more flexible approach to interoperability. Its ability to handle multi-format references without mandatory conversion helps maintain source data integrity while facilitating collaboration between teams using different CAD systems.

Advanced Interoperability Features

Beyond standard data exchange capabilities, MicroStation offers advanced features that optimize interoperability in complex scenarios. These tools allow engineers to effectively manage multi-CAD projects while preserving the richness of technical data.

Advanced Translation and Exchange Features

- Complete support for complex DWG objects - Multileaders, annotation objects, sublayers, and tables

- Integration with Oracle Spatial databases - Connectivity with Oracle 12c for geospatial data management

- Incorporation of high-resolution 3D models - Support for models created through photogrammetry

- Georeferenced export - Ability to export to Google Earth with correct altitude preservation

- 3D printing support - Export to 3D printing formats with texture preservation

How to Ensure Data Consistency During Multi-CAD Exchanges?

MicroStation integrates several validation mechanisms that ensure data quality during exchanges between different CAD systems:

- Automatic detection and repair of geometric errors

- Verification of compliance with exchange standards

- Conversion audit reports with identification of critical elements

- Preservation of assembly hierarchical structures

- Maintenance of component trees and their relationships

CAD Interop Solutions for MicroStation Format

CAD Interop distributes specialized solutions that complement and extend MicroStation's native interoperability capabilities. These tools provide advanced visualization, analysis, and data preparation functionalities that address specific needs of MicroStation users.

3DViewStation: Advanced Visualization and Analysis of MicroStation Models

3DViewStation is a powerful visualization and analysis solution offering complete support for the MicroStation DGN format. It allows companies to extend accessibility of MicroStation data throughout the organization without requiring full licenses for each user.

Key Features of 3DViewStation for MicroStation

- High-performance visualization of complex DGN models with reduced system footprint

- Advanced technical analysis - Measurement, sectioning, model comparison

- Exploded view generation for technical documentation

- Bidirectional conversion between MicroStation and numerous formats (STEP, JT, 3D PDF)

- Creation of technical animations from MicroStation models

- Extraction of PMI (Product Manufacturing Information) and 3D annotations

3DViewStation constitutes an ideal solution for extended teams requiring access to MicroStation data without modifying original files. Its ability to convert to MicroStation format also allows integration of data from other CAD systems into the MicroStation environment.

CADfix: Repair and Simplification of MicroStation Data

CADfix is a specialized solution for validation, repair, and optimization of CAD models. For MicroStation users, CADfix offers advanced data preparation capabilities that go beyond the native functionalities of the software.

CADfix Capabilities for MicroStation Data

- Advanced geometric healing - Detection and correction of complex errors in B-rep models

- Intelligent simplification of voluminous assemblies for visualization or analysis

- Model validation according to exchange standard requirements or internal processes

- Manufacturing preparation - Adaptation of models for CAM processes or 3D printing

- High-precision conversion between MicroStation and other CAD formats

- Controlled defeaturing - Selective removal of non-essential features

CADfix effectively resolves data quality issues that can occur during exchanges between MicroStation and other CAD systems. Its ability to maintain geometric integrity while optimizing models makes it a valuable tool for heterogeneous engineering environments.

Why Use Specialized Solutions with MicroStation?

Although MicroStation offers native interoperability capabilities, specialized solutions like 3DViewStation and CADfix provide several complementary advantages:

- More thorough processing of complex data quality issues

- Extension of visualization and analysis capabilities without full licenses

- Automation of data preparation workflows for specific processes

- Specialized tools adapted to particular business needs

- Facilitated integration with other enterprise systems (PLM, ERP)

Strategies and Best Practices for Optimal Interoperability

Optimizing interoperability in an environment involving MicroStation requires adopting appropriate strategies and methodologies. These best practices help minimize conversion problems and maximize the quality of data exchanges.

Fundamental Principles for MicroStation Data Exchange

- Avoid unnecessary conversions - Prioritize direct referencing when possible

- Establish consistent naming conventions and organization across platforms

- Document translation processes and their parameters to ensure reproducibility

- Systematically validate converted data before production use

- Maintain a library of standard components in the various required formats

Optimal Configuration for Interoperability

MicroStation parameter configuration directly influences the quality of data exchanges. Here are the essential aspects to consider:

- Appropriate definition of units and tolerances for each project

- Seed file parameter configuration adapted to planned exchanges

- Establishment of specific templates for multi-CAD projects

- Setting import/export options according to project requirements

- Creation of documented workflows for recurring translation processes

How to Effectively Structure a Project Involving Multiple CAD Formats?

The structure of a multi-CAD project with MicroStation should follow these principles:

- Organize data by discipline rather than by format

- Maintain a clear file tree with limited hierarchical levels

- Use worksets to isolate data from different sources

- Establish a central directory for multi-format external references

- Implement a versioning system adapted to multi-CAD exchanges

Conclusion

CAD interoperability represents a strategic issue for companies using MicroStation in multi-software environments. MicroStation's native capabilities, combined with specialized solutions like 3DViewStation and CADfix distributed by CAD Interop, offer a complete ecosystem to effectively address technical data exchange challenges.

By adopting the best practices presented in this guide, engineering teams can optimize their workflows involving MicroStation, reduce risks associated with data conversions, and improve collaboration between different disciplines. Interoperability no longer constitutes an obstacle but becomes an efficiency lever in managing the lifecycle of engineering products and projects.

To deepen your mastery of MicroStation interoperability or explore solutions adapted to your specific needs, don't hesitate to contact CAD Interop experts who can guide you toward the most relevant tools and methodologies for your technical context.

In today's industrial landscape, CAD data interoperability is a major challenge for engineering, energy, and process industries. AVEVA PDMS and AVEVA E3D Design software are essential benchmarks in this field, offering advanced features for 3D modeling of complex facilities. This in-depth analysis explores their technical characteristics, recent developments, and integration into modern workflows, while highlighting the interoperability solutions offered by CAD Interop to optimize the exchange and management of design data.

Technological Context and Industrial Challenges

Evolving Plant Design Needs

Process industries (petrochemicals, energy, pharmaceuticals) and naval sectors are facing increasingly complex projects, requiring tools capable of managing multi-site 3D models with thousands of components. Challenges include coordination between disciplines (piping, structural, electrical), revision management, and collaboration with external partners using disparate software.

AVEVA PDMS, developed in the 1980s, marked a revolution thanks to its parametric approach and centralized database. However, the emergence of new methodologies such as BIM (Building Information Modeling) and increased simulation requirements have led to the development of AVEVA E3D Design, a direct successor incorporating expanded capabilities.

Limitations of Older Generations of Software

Although PDMS remains widely deployed, its monolithic architecture presents constraints in modern contexts:

- Difficulty integrating with PLM/ERP systems

- Limitations in managing large models (>500,000 elements)

- Time-consuming file conversion processes for external collaborations

- User interface poorly suited to agile workflows.

These limitations explain the gradual migration to E3D Design, whose performance has been optimized for megaprojects, with productivity gains estimated at between 30% and 50% off the preliminary design phases.

PDMS/E3D Design Comparative Analysis: Technical Architecture and Key Features

AVEVA PDMS: Historical Foundations

- Parametric Modeling: Library of standard components (ASME, DIN, ISO)

- Clash Management: Automatic detection of cross-disciplinary interference

- Multi-User Workflow: Granular locking of elements in editing

- Documentation Generation: Automated assembly drawings, isometrics, and bills of materials.

The native .rvm format integrates a hierarchical representation of data, storing both geometry (NURBS and meshes) and technical metadata (materials, operating pressures):

- .rvm: AVEVA Plant Design Management System Template

- .rvs: AVEVA Plant Design Management System Project

- .pdms: AVEVA PDMS Document

The RVM file format can be saved in both binary and ASCII formats. The RVM file supports entities such as:

- Geometry

- Attributes stored on groups

- Textures (via RVS file)

- Cameras and camera tracks (via RVS file)

- Clip planes (via RVS file)

- Panels (via RVS file)

- Tags (via RVS file)

- Labels (via RVS file)

- Translucency (via RVS file)

- PDMS origin points

AVEVA E3D Design: The Technological Evolution

- Associative Modeling: Dynamic Data Linking P&ID

- Cloud Integration: Real-time collaboration via AVEVA Connect

- Advanced Clash Management: AI-based detection algorithms

- Extensive Interoperability: Native support for IFC 4.3 and STEP AP242 formats.

The .e3d data structure introduces a built-in versioning system and LZ77 compression mechanisms for files larger than 10 GB. Comparative tests show a 40% reduction in loading time for complex models compared to PDMS.

Exchange Capacity Comparison Table

| Criterion | PDMS (.rvm) | E3D Design (.e3d) |

|---|---|---|

| Export formats | 15+ (STEP, IGES) | 25+ (JT, 3D PDF) |

| Geometric precision | ±0.1 mm | ±0.01 mm |

| Technical metadata | Proprietary | ISO Standardized |

| Data Compression | No | LZ77 (5:1 ratio) |

| LOD Support | Level 2 | Levels 1-4 |

This table summarizes E3D Design's major advances in interoperability, crucial for multi-software workflows.

Strategic Migration to E3D Design

Planning and Best Practices

Transitioning from PDMS requires a structured approach :

- Existing Data Audit: Analysis of .rvm/.pdms files to identify potential incompatibilities

- Progressive Conversion: Use of AVEVA Migration Toolkit with batch validation

- Team Training: e-Learning modules tailored to specific business lines (engineering, purchasing, construction)

- System Integration: Custom connectors for SAP/Teamcenter ERPs.

Case studies at TechnipFMC reveal a 70% reduction in conversion errors thanks to E3D Design's backward compatibility algorithms.

Legacy Format Management

CAD Interop offers specialized solutions to maintain access to historical PDMS data :

- Visualization: .rvm/.pdms compatible software with measurements and annotations

- Batch Conversion: Transformation to .e3d with metadata preservation

- Geometric Validation: Topological error detection tools.

These tools enable a seamless transition of ongoing projects while securing existing digital assets.

Integration into modern CAD ecosystems

Interoperability Connectors

AVEVA E3D Design offers broad compatibility with numerous file formats, facilitating data exchange and collaboration between various software tools used in the engineering, procurement, and construction (EPC) industries. Here is a detailed list of supported formats:

Common import and export formats

| Format | Extension | Import | Export |

|---|---|---|---|

| AutoCAD | .dwg, .dxf | ✓ | ✓ |

| MicroStation | .dgn | ✓ | ✓ |

| Navisworks | .nwd, .nwf | ✓ | ✓ |

| PDMS | .rvm, .cdb | ✓ | ✓ |

| SolidWorks | .sldprt, .sldasm | ✓ | ✓ |

| STEP | .stp, .step, AP203, AP214, AP242 | ✓ | ✓ |

| IGES | .igs, .iges | ✓ | ✓ |

| STL | .stl | ✓ | ✓ |

| VRML | .wrl | ✓ | ✓ |

| CATIA V4 | .model, .exp | ✓ | |

| CATIA V5/V6 | .CATPart, .CATProduct | ✓ | |

| Creo (Pro/E) | .prt, .asm | ✓ | |

| Inventor | .ipt, .iam | ✓ |

Additional Specific Formats

- Parasolid: (.x_t, .x_b) - Full import and export

- ACIS: (.sat, .sab) - Full import and export

- Images: (.bmp, .jpg, .tif) - Import only

These formats enable extensive interoperability with the main CAD software used in industry.

Interoperability Methods with AVEVA

Optimizing Data Exchange

- Using Formats neutral: Prefer formats like STEP to maximize compatibility between different CAD tools while preserving general attributesmetric and technical.

- Simplify Complex Models: Use tools like CADfix PPS to reduce file size before importing into AVEVA E3D. This improves performance and reduces processing times for large models.

Attribute and Metadata Management

- When exchanging with Tekla Structures or other BIM software, favor exporting to IFC format to ensure that essential attributes (materials, dimensions) are preserved.

- For legacy PDMS files (.rvm), ensure that entities such as textures or tags are correctly transferred via the associated RVS file.

Multi-Software Collaboration

- Directly integrate data from other disciplines using AVEVA Unified Engineering connectors. This allows for automatic updates between electrical schematics and the 3D model.

- Use compatible visualization solutions like 3DViewStation to quickly validate models without requiring prior conversion.

Post-Conversion Quality Control

After each conversion or import:

- Check for interferences and clashes using E3D Design's built-in tools.

- Compare models before and after conversion with specialized software to detect any loss of information or geometric errors.

These tips ensure a smooth transition between software while minimizing the risk of errors in your industrial projects.

Future Outlook and Innovations

AI and Digital Twin Integration

The latest versions of E3D Design integrate artificial intelligence modules for:

- Automatic Route Generation: Optimization of piping networks

- Predictive Interference Detection: Algorithms based on project history

- Documentation Synthesis: Automatic generation of technical reports.

Integration with AVEVA Process Simulation creates a complete digital twin, enabling multiphysics simulations directly on the 3D model.

Extended Reality (XR) Developments

CAD Interop develops immersive visualization solutions:

- Virtual Reality: Collaborative Project Reviews in a CAVE Environment

- Cloud Streaming: Lightweight access to models via a web browser.

These technologies reduce validation times by 40% while improving the early detection of design issues.

Conclusion

Migrating to AVEVA E3D Design represents a strategic opportunity for companies looking to optimize their 3D factory design processes. Combined with CAD Interop's interoperability solutions, this software enables seamless integration into modern CAD ecosystems while preserving access to historical data. The gains in productivity, deliverable quality, and error reduction fully justify the investment, particularly in the current context of accelerating complex industrial projects.

Table of Contents

- Introduction to ZW3D and Interoperability

- History and Evolution of ZW3D

- The Overdrive Geometric Engine

- Formats and Standards Supported by ZW3D

- Interoperability with Other CAD Systems

- SimLab: Immersive Experience Solution for ZW3D

- Best Practices for Exchanging ZW3D Models

- Conclusion

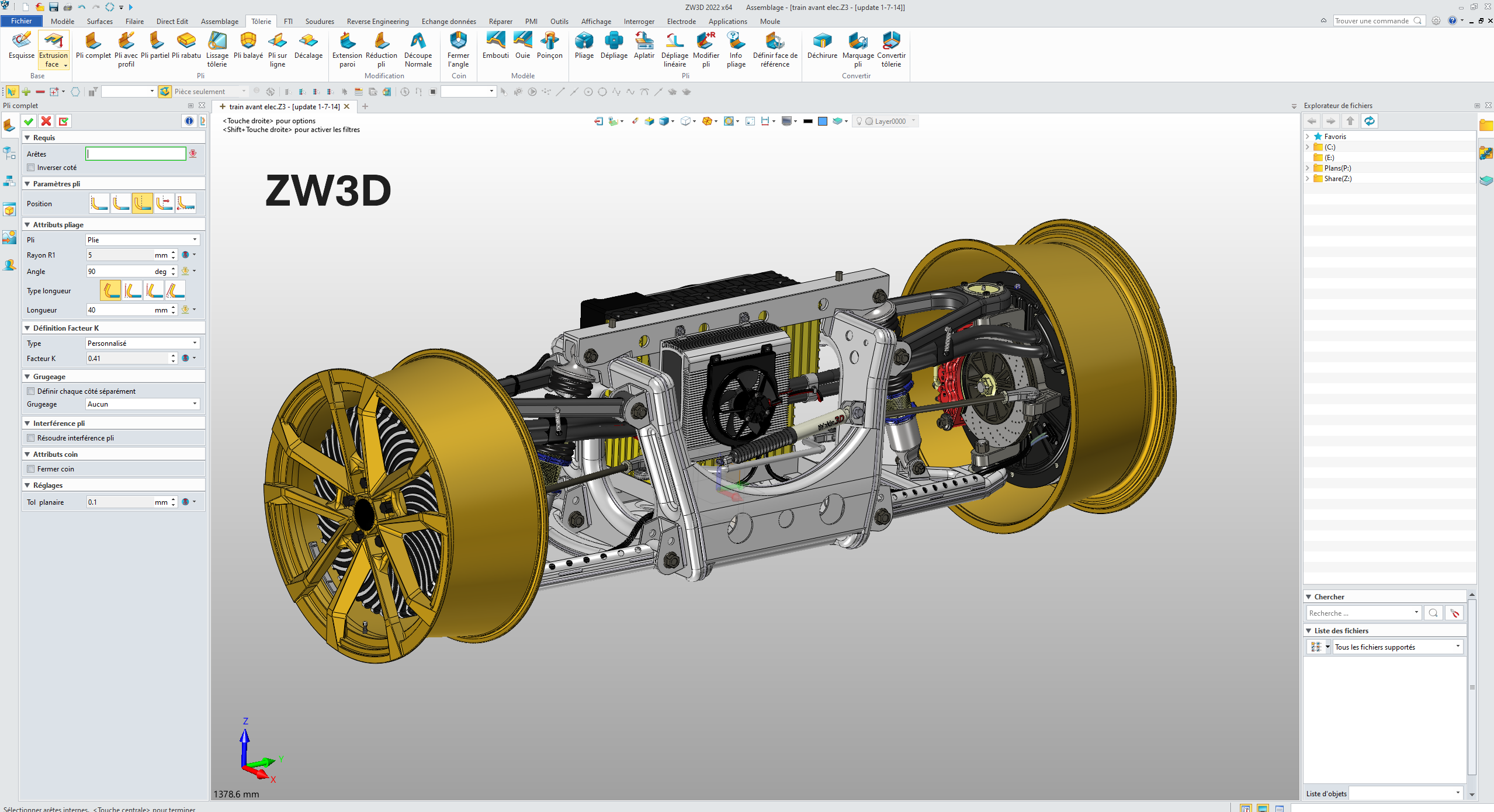

Introduction to ZW3D and Interoperability

Computer-aided design data interoperability represents a major challenge for industrial companies working with multiple CAD systems. ZW3D positions itself as a high-performance solution to these technical data exchange issues, offering a complete response to CAD interoperability needs.

ZW3D is an advanced 3D CAD/CAM software developed by ZWSOFT, designed to offer an all-in-one solution for product design, manufacturing, and simulation. What particularly distinguishes ZW3D is its exceptional native interoperability capability with most CAD systems on the market.

The main advantages in terms of interoperability are:

- Direct opening of native files from many competing CAD systems

- Wide range of import and export formats

- Data translation without loss of geometric quality

- No need for third-party converters or add-ons in most cases

- Easy sharing and exchange with partners and suppliers

History and Evolution of ZW3D

Innovative Origins

Appearing in the CAD landscape in 1986 under the original name ModelMATE, ZW3D represented one of the very first commercial solid modelers operating on PC. Developed by Mark Vorwaller, this software already foreshadowed the future importance of technical data interoperability.

The year 1999 marks a decisive turning point with the introduction of Solid-Surface hybrid modeling technology, making ZW3D the first hybrid modeler in the industry. This major innovation removed the traditional boundaries between solid and surface modeling, allowing solid functionalities to be applied directly to surfaces.

Recognition and Continuous Development

Following a strategic alliance with SNK (Japanese machine tool company), ZW3D transformed into one of the first complete integrated design-manufacturing solutions. This evolution earned it the prestigious "Gold Winner & Product of the Year" award from NASA Tech Brief in 2002.

In 2010, ZWSOFT acquired the technologies and R&D team of VX Corporation in the United States, significantly enriching its multi-CAD interoperability and data exchange capabilities. Since then, ZW3D's continuous development has focused on improving data exchange performance with the main players in the CAD market.

The Overdrive Geometric Engine

A Powerful Proprietary Geometric Kernel

The core of ZW3D's CAD interoperability lies in its Overdrive geometric engine, a 3D modeling technology with completely independent intellectual property. Developed over more than 10 years, this kernel ensures the consistency of 3D models in their geometric shapes and spatial relationships thanks to sophisticated algorithms.

Overdrive offers a unique combination of features focused on interoperability:

- Smooth import and export of models from/to other systems

- Automated detection and repair of geometric defects

- Hybrid solid-surface modeling in a unified environment

- Coexistence of parametric and direct modeling

- Direct boolean operations between solids and surfaces

Proven Industrial Applications

The Overdrive engine has proven its effectiveness in various industrial sectors such as automotive, mechanical engineering, and electronics. It also serves as a technological foundation for other ZWSOFT solutions such as ZWSim-EM, ZWSim Structural, and ZWMeshWork.

What particularly distinguishes Overdrive in the field of interoperability is its ability to maintain model integrity during format conversions, significantly reducing geometric problems that typically occur during exchanges between different CAD systems.

Formats and Standards Supported by ZW3D

Broad Compatibility for Maximum Interoperability

ZW3D excels in supporting a wide range of CAD formats, enabling smooth collaboration with partners and suppliers using other systems. This section details the import and export formats supported by ZW3D.

The table below presents the main formats compatible with ZW3D, classified by categories:

| Category | Format | Extensions |

|---|---|---|

| Native Formats | Catia V4 | .model, .exp, .session |

| Catia V5/V6 | .CATPart, .CATProduct, .CATDrawing, .CGR, .3DXML | |

| NX(UG) | .prt | |

| Creo(Pro/E) | .prt, .prt*, .asm, .asm.* | |

| SolidWorks | .sldprt, .sldasm | |

| SolidWorks_2D | .slddrw | |

| SolidEdge | .par, .asm, .psm | |

| Inventor | .ipt, .iam | |

| Neutral Standards | ACIS | .sat, .sab, .asat, .asab |

| STEP | .stp, .step, .stpz | |

| IGES | .ige, .iges | |

| Parasolid | .x_t, .x_b, .xmt_txt, .xmt_bin | |

| JT | .jt | |

| VDA | .vda | |

| 2D Format | DWG | .dwg |

| DXF | .dxf | |

| Mesh and Visualization | STL | .stl |

| OBJ | .obj | |

| 3DXML | .3dxml | |

| XCGM | .xcgm | |

| Others | Image File | .bmp, .gif, .jpg, .jpeg, .tif, .tiff |

| Neutral File | .z3n, .v3n | |

| PartSolutions | .ps2, .ps3 |

This extensive compatibility enables efficient 3D data conversion and facilitates long-term archiving of technical models in standard formats such as STEP or JT.

Interoperability with Other CAD Systems

Versatile Alternative to Established Systems

ZW3D positions itself as an excellent alternative to established CAD solutions such as SolidWorks, Inventor, or Rhino, with similar functionalities but a differentiated approach to interoperability. Its ability to directly open and modify files from other CAD systems without third-party converters represents a major asset for companies working in multi-CAD environments.

ZW3D's interoperability capabilities revolve around three main axes:

- Hybrid volume-surface modeling: Enables precise design simultaneously integrating volumetric and surface approaches, facilitating exchanges with different systems

- Native multi-CAD compatibility: Works directly with SolidWorks, CATIA, NX and other files without intermediate conversions

- CAD-CAM integration: Smooth transfer of design data to manufacturing modules

Interoperability Use Cases

In a typical industrial environment, ZW3D can serve as a central hub for data translation between different CAD systems. For example, a company receiving CATIA models from its clients can open them in ZW3D, modify them if necessary, and then export them to SolidWorks for its manufacturing partners.

This technical data exchange flexibility allows companies to maintain their preferred CAD system while effectively collaborating with partners using other platforms, thus eliminating traditional interoperability barriers.

SimLab: Immersive Experience Solution for ZW3D

Advanced Interactive Visualization

SimLab Composer, distributed by CAD Interop, represents a powerful solution for creating immersive experiences from ZW3D models. This free plugin establishes an intermediate layer between ZW3D and the SimLab Composer application, creating an active link that keeps data synchronized between the two environments.

This integration eliminates the need for repetitive exports and imports: each modification of the model in ZW3D is automatically reflected in SimLab Composer, while preserving the changes made in the visualization environment.

Key Features for Technical Collaboration

SimLab Composer enriches the ZW3D ecosystem with advanced visualization and sharing capabilities:

- Creation of interactive VR experiences in minutes

- Realistic and fast rendering with multiple output formats (images, videos, animations, 360° views)

- Generation of 3D PDF documents integrating interactive 3D views

- Application of materials and texture baking for realistic rendering

- Mechanism simulation from ZW3D models

These features facilitate technical communication between teams and with clients, transforming complex CAD models into understandable visualizations for all project stakeholders, even those without CAD systems.

Best Practices for Exchanging ZW3D Models

Optimizing Interoperability Flows

To maximize the efficiency of data exchanges with ZW3D, certain recommended practices help avoid common data translation problems and ensure model integrity:

- Prefer standard formats such as STEP or JT for exchanges with external partners

- Use the native ZW3D format (.z3) to preserve construction history between collaborators

- Leverage hybrid modeling to facilitate exchanges with systems centered on surfaces or solids

- Systematically verify geometric quality after import/export with integrated healing tools

How to Effectively Manage Multi-CAD Conversions?

For companies working in a multi-CAD environment, adopting a structured data exchange process with ZW3D can significantly improve productivity:

- Define clear exchange standards for each partner CAD system

- Document optimal import/export parameters for each format

- Implement systematic geometric validation after conversion

- Use SimLab to visually validate converted models

- Maintain a library of reference models to test conversions

These practices help establish a robust interoperability workflow around ZW3D, reducing conversion errors and accelerating product development cycles.

Conclusion

CAD data interoperability represents a strategic issue for modern industrial companies, and ZW3D offers a high-performance solution to this problem thanks to its extensive technical data exchange capabilities. With its Overdrive geometric engine, compatibility with a wide range of CAD formats, and hybrid modeling approach, ZW3D enables smooth integration into multi-CAD ecosystems.

The main assets of ZW3D for interoperability can be summarized as follows:

- Native support for numerous standard and proprietary formats

- Advanced modeling capabilities facilitating exchanges between systems

- Integration with SimLab for immersive visualization and sharing

- Flexibility of use as a central data exchange platform

For companies looking to optimize their technical data exchange processes, ZW3D represents a complete solution that can either serve as a main CAD system or as an interoperability hub between different platforms. Its ability to maintain model integrity during conversions makes it a valuable tool for any collaborative multi-CAD design environment.

- History and Evolution of Revit

- Revit's Geometric Engine and Its Specificities

- Exchange Formats Supported by Revit

- IFC4 Format Support: A Decisive Step Towards Complete Interoperability

- CAD Interop Solutions for Revit Interoperability

- Revit Interoperability Tips

- Best Practices for Exchanging Revit Models

- Conclusion

Autodesk Revit has established itself as an essential tool for building and construction professionals. Its ability to create 3D parametric models that integrate project data makes it a preferred solution for Building Information Modeling (BIM). This article explores the essential aspects of data interoperability with Revit, a crucial issue for multidisciplinary collaboration in construction projects.

History and Evolution of Revit

Revit was originally developed by Charles River Software, founded in 1997 by Leonid Raiz and Irwin Jungreis, former developers of PTC's Pro/Engineer software. Their goal was to bring parametric modeling, common in mechanical CAD, to the building industry. The first version of Revit was launched on April 5, 2000.

The company was renamed Revit Technology Corporation in January 2000, then acquired by Autodesk for $133 million in 2002. This acquisition accelerated the development and improvement of the software. The name "Revit" is actually a contraction of "Revise-Instantly," reflecting the software's ability to update all linked elements when a modification is made to one part of the model.

Over the years, Revit has been enriched with new features:

- 2005: Introduction of Revit Structure

- 2006: Launch of Revit MEP

- 2011: Release of Dynamo in beta version

- 2012: Introduction of Revit LT, a lighter version of the software

In 2025, more than 14,302 companies worldwide use Revit as a CAD tool, with 1,610 specifically in the field of architecture. This massive adoption demonstrates its dominant position in the AEC (Architecture, Engineering and Construction) sector.

Revit's Geometric Engine and Its Specificities

Revit's geometric engine is based on specific technical choices that distinguish it from other CAD systems. Unlike software such as Inventor or AutoCAD, Revit uses parameterized curves and surfaces to represent geometric edges and faces respectively.

A notable peculiarity concerns the representation of cylindrical shapes: in Revit, a complete cylindrical face is generally divided into two half-cylinders. This approach results from a deliberate choice in the design of Revit's geometric core to avoid ambiguities in surface parameterization.

Developer John Mitchell from the Revit team explains this technical choice:

"Revit uses parameterized curves and surfaces to represent the geometry of edges and faces. For example, a spherical surface essentially uses latitude and longitude as coordinates. By prohibiting closed edges and faces, we represent the sphere using two hemispherical faces, which eliminates any ambiguity when determining coordinates."

This approach, although it may seem counter-intuitive for users accustomed to other CAD systems, offers advantages in terms of consistency and reliability of the parametric model.

Exchange Formats Supported by Revit

Revit supports a wide range of exchange formats to facilitate interoperability with other CAD and BIM applications. This flexibility allows AEC professionals to integrate Revit into various workflows and exchange data with different disciplines.

Standard Import and Export Formats

Revit supports the following formats for data import and/or export:

- DGN (MicroStation Design File): Used to exchange data with Bentley MicroStation users

- DWF/DWFX (Design Web Format): Lightweight format developed by Autodesk for sharing and visualization

- DWG/DXF (AutoCAD Drawing): AutoCAD native formats, widely used in the industry

- IFC (Industry Foundation Classes): Essential open format for BIM interoperability

- SAT (ACIS SAT): File format for solid geometry exchange

- SKP (SketchUp): SketchUp native format, used for importing architectural concepts

Formats Added in Revit 2023

Version 2023 extended interoperability capabilities with the addition of three important formats:

- AXM (FormIt): Autodesk FormIt native format, now supported for import and direct linking in Revit

- OBJ (Wavefront Object): Versatile 3D exchange format, initially supported for import in version 2022.1, then for linking in version 2023

- STL (Stereolithography): Standard format for 3D printing and additive manufacturing

Format Added in Revit 2025

- STEP/STP : ISO standard format widely used in mechanical and manufacturing industries, newly supported in Revit 2025

Recent Developments by Version

Revit 2025

- Improved support for open formats with optimized category mapping for IFC export

- Introduction of support for STEP format (STP), widely used in mechanical and manufacturing industries

- Tracking and visualization of changes in linked models stored on Autodesk Docs, including for IFC and NWC (Navisworks) links

- Enhanced integration with Twinmotion for visualization, with a new "Twinmotion Substitution" parameter

Revit 2023

- Improved workflows between Revit and FormIt Pro with the ability to directly link FormIt files (AXM) in Revit

- Better support for placement and appearance of imported CAD file formats

- New "Allow cut in views" parameter for 3D elements from CAD files

- Advanced features for mapping standard IFC attributes to model elements

Revit 2022

- IFC4 certification for architecture and structure export, making Revit the first software to support IFC4 reference view export for multiple disciplines

- Improved interoperability with Inventor, allowing export of Inventor assemblies to RVT files

These developments demonstrate Autodesk's ongoing commitment to improving Revit's interoperability with other platforms and formats, thus facilitating collaborative workflows in the AEC sector.

IFC4 Format Support: A Decisive Step Towards Complete Interoperability

The IFC (Industry Foundation Classes) format is essential for BIM interoperability, and Revit offers complete support for this format. For imports, Revit supports IFC files based on IFC4, IFC2x3, IFC2x2, and IFC2x standards. For exports, it supports IFC4, IFC2x3, and IFC2x2 standards.

Advantages of IFC4

IFC4 represents a major advancement over previous versions, with significant improvements:

- File size reduction : IFC4 offers much more efficient ways to store geometry, both for meshes and parametric shapes. For example, an IFC file produced from Revit of a single object weighing 16,098 kB can be reduced to 4,487 kB when re-exported in IFC4, without any loss of geometric detail.

- Better mesh representation : The new support for tessellated forms allows a much more efficient description of meshes compared to the faceted BREPs of IFC2X3.

- Improved parametric geometry support : IFC4 enhances Revit's ability to export parametric geometry, thus preserving the intelligence of the model.

IFC Export Tools in Revit

Autodesk regularly updates Revit's IFC exporter to integrate new features and fix bugs. The IFC Export Alternate UI offers additional flexibility in choosing export options. Both tools are available on the Autodesk App Store and must be downloaded and installed manually.

For English-speaking users, the "IFC Exporter for Revit" provides a set of parameter sets that can be used directly for exports. It is possible to add, delete, or modify an existing parameter set to adapt it to the specific needs of the project.

CAD Interop Solutions for Revit Interoperability

3DViewStation: Advanced Visualization and Analysis of Revit Models

3DViewStation is a high-performance solution distributed by CAD Interop that allows visualization and analysis of CAD models, including those created with Revit, without requiring installation of the original software. This solution offers several advantages for professionals working with Revit data:

- Fast and lightweight visualization of complex BIM models

- Geometric analysis tools to verify model quality

- Measurement and section features to examine different parts of the model in detail

- Ability to combine data from different sources for a global view of the project

- Export to various formats to facilitate communication with stakeholders who do not have BIM software

3DViewStation integrates perfectly into BIM workflows and is an ideal complement to Revit for teams that need to share and analyze complex models.

SimLab for Immersive Experiences from Revit Models

SimLab, also distributed by CAD Interop, is an innovative solution that transforms Revit models into immersive experiences. This platform facilitates:

- The creation of virtual reality (VR) environments from Revit models

- The development of augmented reality (AR) applications to visualize projects in their real context

- The development of interactive presentations for clients and stakeholders

- The simulation of space occupation and usage scenarios

- The optimization of designs through a more intuitive understanding of 3D spaces

SimLab transforms Revit's technical data into powerful communication tools, thus facilitating collaboration between designers, clients, and end users.

Revit Interoperability Tips

Optimizing DWG Exports

To ensure optimal conversion to DWG format:

- Configure layers and line styles in Revit before export

- Use project-specific export settings to maintain consistency

- Check the selected DWG version to ensure compatibility with recipients

Improving IFC Exchanges

To maximize the quality of IFC exchanges:

- Use the alternative IFC export UI for more precise control

- Create custom export parameter sets for different project types

- Verify that all elements are correctly mapped to the appropriate IFC classes

- Prefer using IFC4 to reduce file size and improve geometric accuracy

Managing Complex Assemblies

When transferring models with complex assemblies:

- Check the assembly hierarchy after import/export

- Use dedicated export views to precisely control what is shared

- Document relationships between components that might be affected during conversions

Best Practices for Exchanging Revit Models

Model Preparation

Before sharing Revit models:

- Clean the model of temporary or non-essential elements

- Check the consistency of schedules and annotations

- Ensure all links are properly managed

- Use the interference checking tool to identify and resolve potential conflicts

Data Structuring

Good data structuring facilitates interoperability:

- Organize the model with logical sub-projects

- Use well-named and documented families and types

- Apply consistent project standards to facilitate interpretation by other users

- Properly populate metadata for better utilization by other software

Exchange Documentation

For effective collaboration:

- Document software versions used

- Specify exchange formats and applied export parameters

- Clearly identify known limitations or elements requiring special attention

- Establish a BIM exchange protocol with all project stakeholders

Conclusion

CAD data interoperability with Revit is a crucial issue for professionals in the AEC sector. Revit's import and export capabilities, particularly with the IFC4 format, offer extensive possibilities for interdisciplinary collaboration. Solutions offered by CAD Interop, such as 3DViewStation and SimLab, enrich this ecosystem by providing complementary functionalities for visualization, analysis, and creation of immersive experiences.

By applying the best practices and tips presented in this article, Revit users can optimize their data exchange workflows and thus improve the overall efficiency of their BIM projects. Mastery of these technical aspects constitutes a significant competitive advantage in a sector where digital collaboration has become essential.

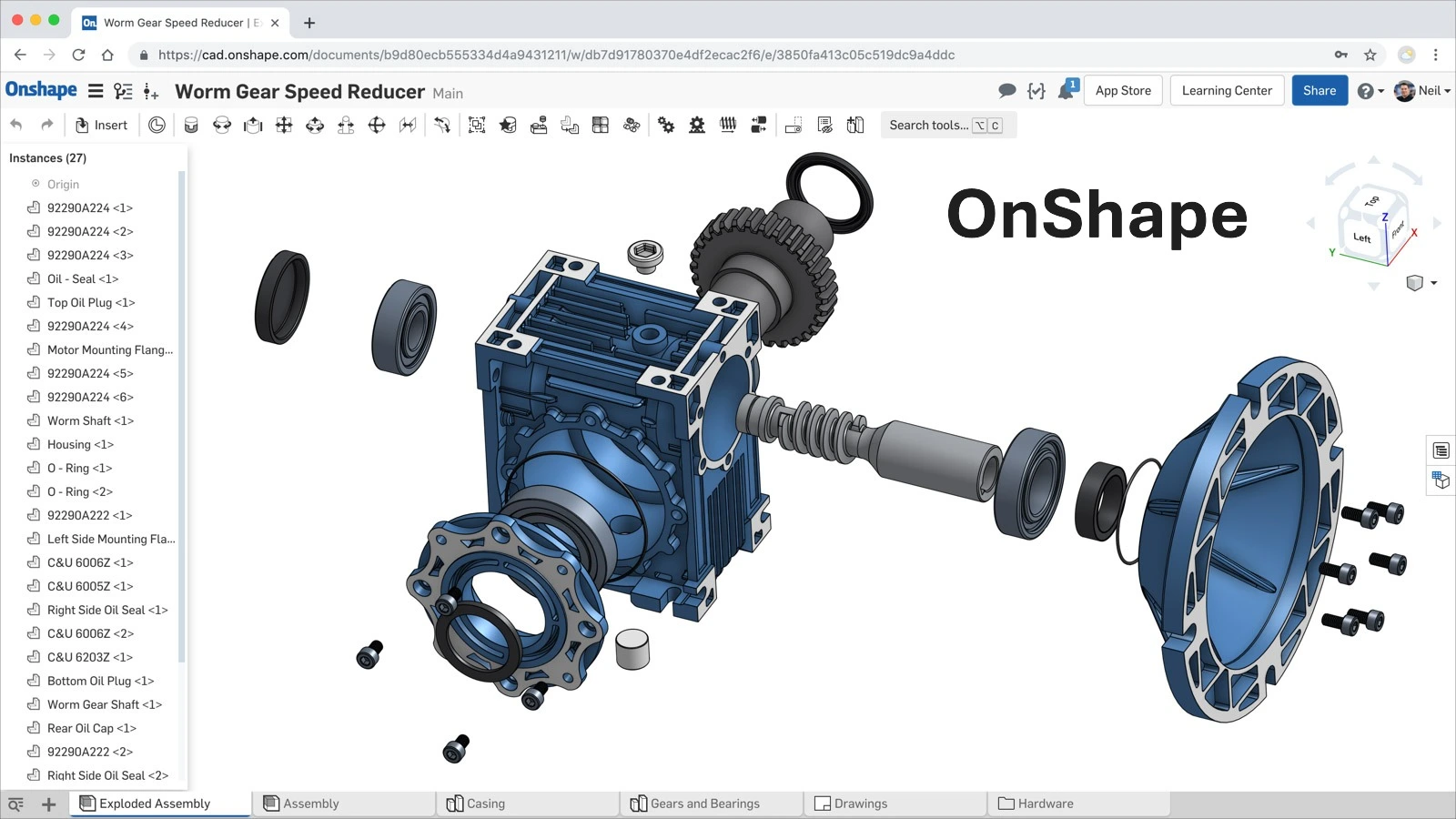

OnShape is a computer-aided design (CAD) software entirely cloud-based, offering a complete 3D modeling experience for product design, development, and manufacturing. It stands out with its SaaS (Software as a Service) approach that allows access to the software from any device with an internet connection, without prior installation or local maintenance.

Founded in 2012 by Jon Hirschtick, John McEleney, and Dave Corcoran - all former SolidWorks executives - OnShape revolutionized the CAD world with its cloud-native approach. Here are the key milestones in its development:

- March 2015: Launch of the public beta version, including OnShape for iPhone

- August 2015: Release of the OnShape application for Android

- December 2015: Full commercial launch and opening of the OnShape App Store

- May 2016: Introduction of FeatureScript, an open-source programming language to create and customize CAD features

- November 2019: Acquisition by PTC for $470 million

- February 2024: iOS support for Apple Vision Pro, enabling real applications of CAD models in augmented reality

Native Format and Geometric Engine

Proprietary Data Format

OnShape uses a proprietary file format called "OnShape Document," stored exclusively in the cloud. This format contains all information related to the 3D model, including its geometry, material properties, and complete design history.

Parasolid: OnShape's Technological Core

OnShape relies on the Parasolid geometric engine, developed by Siemens PLM Software, one of the most robust and widespread kernels in the CAD industry. This strategic choice allows OnShape to benefit from proven technology used by many other professional CAD systems.

The Parasolid kernel is responsible for essential geometric operations in OnShape:

- Precise modeling of B-Rep (Boundary Representation) solids and surfaces

- Complex Boolean operations (union, subtraction, intersection)

- NURBS curves and surfaces management

- High-precision topology calculations and tessellation

- Complex assembly manipulation

This engine also enables native compatibility with Parasolid files (.x_t and .x_b), facilitating data exchange with other systems using the same kernel such as SolidWorks, NX, and Solid Edge.

OnShape's Interoperability Capabilities

OnShape stands out with its complete support for CAD data exchange standards. The system integrates powerful converters allowing import and export of a wide range of native and neutral formats. This flexibility greatly facilitates project migration from traditional CAD systems and collaboration with partners using different platforms.

OnShape uses CrossCad/Ware technology from Datakit to ensure 3D CAD data interoperability. This solution is integrated into the cloud platform to enable efficient translation between the cloud environment and traditional CAD systems.

Part Formats Supported by OnShape

| Format | Import | Export |

|---|---|---|

| Parasolid B-rep (.x_t, .x_b) | v10.0 to v37.0 | v25.0 to v37.0 |

| Parasolid mesh | v28.0 to v37.0 (visualization only) | v28.0 to v37.0 |

| Parasolid mixed model | v32.0+ | ✓ |

| ACIS (.sat) | up to 2023 1.0 | Version 5 |

| STEP (.stp, .step) | AP203, AP214, AP242 (geometry and colors) | AP203, AP214, AP242 |

| IGES (.igs, .iges) | up to 5.3 | 5.3 |

| CATIA v4 | 4.15 to 4.24 | ✗ |

| CATIA v5 | R7 to R33 | ✗ |

| CATIA v6 | R2010x to R2025X | ✗ |

| SOLIDWORKS (.sldprt) | 1999 to 2025 | 2006 |

| Inventor | 9 to 2025 | ✗ |

| Pro/ENGINEER, Creo | Pro/E 2000i to Creo Parametric 11.0 | ✗ |

| JT (.jt) | up to 11.0 | up to 11.0 |

| Rhino (.3dm) | versions 2 to 8 | versions 7 and 8 |

| STL (.stl) | ✓ (visualization only) | ✓ |

| OBJ (.obj) | ✓ (visualization only) | ✓ |

| NX | UG15.0 to NX 2406 Series | ✗ |

| Solid Edge (.par, .psm) | 10 to 2025 | ✗ |

| glTF (.gltf) | version 2.0 | ✓ |

| 3MF | ✓ | ✓ |

| Collada (.dae) | ✗ | 1.4.1 |

| PVZ (.pvz) | ✗ | version 8.0 |

Assembly Formats Supported by OnShape

| Format | Import | Export |

|---|---|---|

| Parasolid B-rep (.x_t, .x_b) | v10.0 to v37.0 | v25.0 to v37.0 |

| Parasolid mixed models | ✗ | ✓ |

| ACIS (.sat) | up to 2023 1.0 | Version 5 |

| STEP (.stp, .step) | AP203, AP214, AP242 | AP203, AP214, AP242 |

| IGES (.igs, .iges) | ✗ | 5.3 |

| CATIA v4 | 4.15 to 4.24 (via .zip) | ✗ |

| CATIA v5 | R7 to R33 (via .zip) | ✗ |

| CATIA v6 | R2010x to R2025X (via .zip) | ✗ |

| SOLIDWORKS | 1999 to 2025 (via Pack and Go .zip) | ✗ |

| Inventor (.iam) | 9 to 2025 | ✗ |

| Pro/ENGINEER, Creo | Pro/E 2000i to Creo Parametric 11.0 | ✗ |

| JT (.jt) | up to 11.0 | up to 11.0 |

| Rhino (.3dm) | versions 2 to 8 | ✗ |

| NX | UG15.0 to NX 2406 Series | ✗ |

| Solid Edge | 10 to 2025 (via .zip) | ✗ |

| STL | ✗ | ✓ |

| glTF (.gltf) | version 2.0 | ✓ |

| 3MF | ✓ | ✓ |

| OBJ (.obj) | ✗ | ✓ |

| Collada (.dae) | ✗ | 1.4.1 |

| PVZ (.pvz) | ✗ | version 8.0 |

Drawing Formats Supported by OnShape

| Format | Import | Export |

|---|---|---|

| AutoCAD (.dwg) | up to 2018 | Release 11-14, 2000-2018 |

| DXF (.dxf) | up to 2013, 2018 | Release 11-14, 2000-2018 |

| DWT (.dwt) | 2013, 2018 | 2013, 2018 |

| SVG | ✗ | ✓ |

| PNG | ✗ | ✓ |

| JPEG | ✗ | ✓ |

Non-CAD Formats Supported by OnShape

| Format | Import | Export |

|---|---|---|

| .mp4 | ✓ | ✗ |

| .png | ✓ | ✗ |

| .jpg/jpeg | ✓ | ✗ |

| .svg | ✓ | ✗ |

| .gif | ✓ | ✗ |

| .txt | ✓ | ✗ |

| .md | ✓ | ✗ |

Parasolid is OnShape's preferred import format for obtaining the best conversion results.

Extensions and Integrations

PCB Studio

OnShape includes PCB Studio, a solution that supports bidirectional exchange of printed circuit board (PCB) designs from ECAD systems. By using standards specifically designed for interoperability, such as Intermediate Data Format (IDF), Incremental Design Exchange (IDX), and EAGLE files (BRD), it is possible to exchange data in both directions between ECAD solutions and OnShape without loss of relevant geometric detail.

PCB Studio builds a shared, searchable, always-synchronized library of electrical components that helps teams reuse components to save time. It also creates a simplified OnShape model for each new component in the ECAD data.

SimLab Composer - Virtual Reality Solution for OnShape

SimLab Composer is integrated with OnShape, meaning that cloud-based documents can be imported directly into SimLab Composer from OnShape's cloud storage. This solution, distributed by CAD Interop, is designed to create interactive visualizations and output variations from your designs.

Key features of SimLab Composer with OnShape:

- Virtual Reality (VR): Easy creation of advanced VR experiences from OnShape models in minutes

- Rendering: Rendering designs in a very fast and realistic progressive engine with different outputs (images, videos and animations, 360° images)

- 3DPDF: Share work by embedding 3D views in PDF files for complete communication

- Texture Baking: Applying materials and texture baking for a realistic appearance when viewing designs

- Mechanism Simulation: Ability to simulate mechanisms created in OnShape

SimLab Composer supports the latest version of OnShape and works on Windows and Mac.

Best Practices for Data Exchange with OnShape

Recommendations for Importing into OnShape

To maximize conversion quality when importing data into OnShape:

- Prefer Parasolid formats (.x_t, .x_b) for best results

- For complex assemblies, use the "Pack and Go" function for SOLIDWORKS

- For other CAD systems, create a ZIP file with the same name as the main assembly

- Check for absence of special characters in filenames

- Use the "Import appearances" option to preserve visual properties

Optimization for Exporting from OnShape

When exporting to other CAD systems:

- For maximum compatibility, prefer STEP AP242 or Parasolid formats

- Use the "Derived" functionality to share simplified models while protecting your intellectual property

- Export in STEP AP242 to preserve colors and metadata

Competitive Advantages of OnShape Interoperability

OnShape's approach to interoperability offers several strategic advantages:

- Optimized Workflows: Reduction of conversion steps when exchanging with different CAD systems

- Cost Reduction: Elimination of third-party conversion software for most formats

- Accelerated Product Development: Facilitated collaboration between teams using different tools

- Enhanced Flexibility: Adaptability to varying requirements of partners and clients

- Simplified Integration: Seamless connection with existing PDM/PLM systems

The robustness of OnShape's interoperability capabilities makes it an ideal solution for companies working in complex multi-CAD environments, where reliable and accurate conversion of 3D data is essential to project success.

Table of Contents

- Presentation of Spirit Software and its Position in the CAD Ecosystem

- History and Evolution of Spirit Data Exchange Capabilities

- Technical Architecture and Geometric Engine of Spirit

- Native and Exchange Formats Supported by Spirit

- Interoperability Solutions Distributed by CAD Interop for Spirit

- Best Practices for Optimizing Spirit Data Exchange

- Specific Challenges and Solutions for Spirit Interoperability

- How to Integrate Spirit into a Long-Term Archiving Strategy

- Frequently Asked Questions about Spirit Interoperability

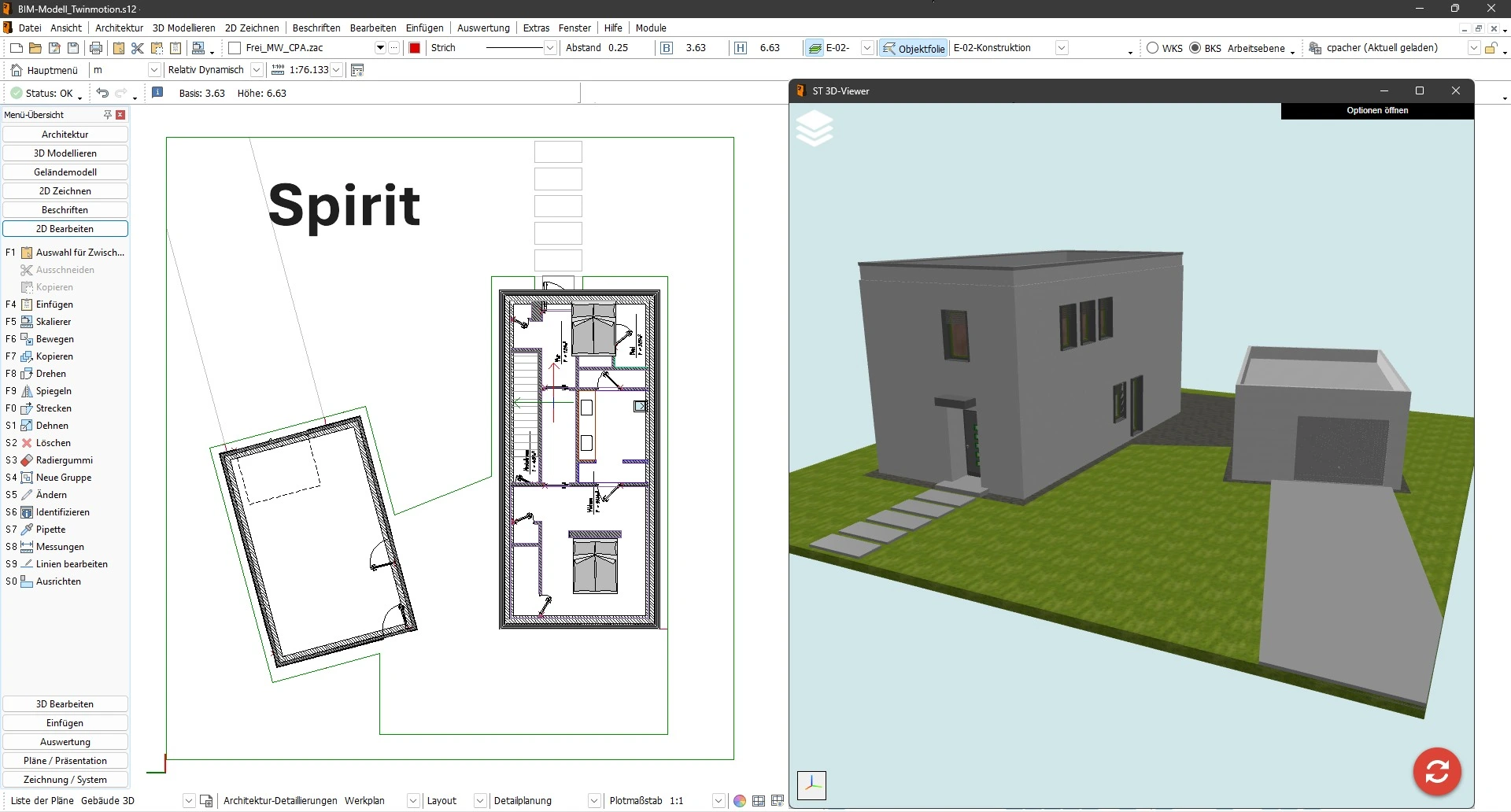

Technical data exchange between different CAD systems represents a major challenge for engineering and design companies. Spirit software, developed by Softtech, offers significant but often overlooked interoperability capabilities. This article presents a comprehensive analysis of Spirit's data exchange functionalities and proposes solutions to optimize the interoperability of your models in a multi-CAD environment.

Presentation of Spirit Software and its Position in the CAD Ecosystem

Spirit is a 2.5D computer-aided design (CAD) software developed by Softtech. 2.5D (also called two-and-a-half-D or pseudo 3D) refers to design technologies that are halfway between 2D and 3D. This software is particularly suited for architectural and civil engineering projects, offering a BIM (Building Information Modeling) solution that allows architects, engineers, and designers to create models with limited depth dimension.

Unlike complete 3D CAD systems, Spirit distinguishes itself with its 2.5D approach that offers users the ability to work using several methods:

- Traditional 2D drawing with extrusion elements

- 2.5D modeling with depth management

- Component-oriented design (particularly useful for the BIM approach)

What makes Spirit particularly interesting in a CAD interoperability context is its ability to integrate into heterogeneous workflows, while recognizing its technical limitations compared to complete 3D systems.

History and Evolution of Spirit Data Exchange Capabilities

The development of Spirit is part of a constant improvement approach based on user feedback and the expertise of Softtech employees, many of whom have practical experience as architects, planners, or engineers. This "from practice" approach has influenced the evolution of the software's interoperability capabilities.

Over the years, Spirit has significantly improved its exchange interfaces to meet the growing demands for collaboration in the industry. The optimization of the IFC (Industry Foundation Classes) interface demonstrates this commitment to implementing a true "open BIM," although developers recognize that the path to perfect interoperability is still long.

Notable improvements include:

- Continuous refinement of the IFC interface

- Optimization of IFC model representation

- Significant improvement in graphic exports

- Development of direct exports to specific formats such as SketchUp 3D

This constant evolution positions Spirit as a committed player in resolving CAD interoperability issues that occur "recurrently and at all stages of a product's lifecycle."

Technical Architecture and Geometric Engine of Spirit

Spirit relies on a technical architecture adapted to its 2.5D nature, which directly influences its CAD data exchange capabilities.

Modeling capabilities and data representation:

Spirit manages several geometric data representations, including:

- Extended 2D models with depth information (2.5D)

- Mesh models for export to formats like STL

- Limited parametric data adapted to architectural design

This 2.5D approach directly influences interoperability possibilities, as the software does not manipulate complete volumetric models like 3D CAD systems do. Spirit also seems to support specialized architectural modeling, as indicated by the ZAC extension (Spirit Architectural Component).

The software's flexibility in terms of interoperability remains one of its strengths in its market segment, allowing users to exchange data with other applications, taking into account the inherent limitations of 2.5D modeling.

Native and Exchange Formats Supported by Spirit

Format support is a key element of CAD interoperability. Spirit distinguishes itself through its compatibility with several file formats, both for import and export, although more limited than complete 3D CAD systems.

Spirit native formats:

| Extension | Description | Usage |

|---|---|---|

| .SPIRIT | Main format for Spirit drawings | Native model saving |

| .ZAC | Spirit Architectural Component | Specific architectural components |

| .BT! | BitSpirit Incomplete Download File | Temporary files |

| .TEW | Wrestling Spirit | Specialized format |

Standard formats for import/export:

| Format | Import | Export | Main Use |

|---|---|---|---|

| DWG/DXF | ✓ | ✓ | Collaboration with AutoCAD users |

| STL | ✓ | ✓ | 3D printing, rapid prototyping |

| SketchUp | ✗ | ✓ | Sharing with construction professionals |

| IFC | ✓ | ✓ | BIM exchange (Building Information Modeling) |

It is important to note that Spirit, as a 2.5D software, cannot import or export advanced 3D formats like STEP or ACIS. This limitation is inherent to its technical architecture and determines the possible interoperability scenarios.

Interoperability Solutions Distributed by CAD Interop for Spirit

CAD Interop offers several solutions specially designed to improve the interoperability of Spirit data in various professional contexts. These tools allow users to fully leverage their Spirit models beyond the limits of the native software.

SimLab Composer for Spirit:

The flagship solution distributed by CAD Interop for Spirit users is SimLab Composer, a powerful integration that transforms CAD models into interactive and immersive experiences. This plugin offers:

- Advanced visualization of Spirit designs in interactive environments

- Creation of immersive experiences from 2.5D technical models

- Use of complete SimLab Composer functionalities directly with Spirit data

This integration perfectly meets the needs for CAD visualization without a complete CAD license, thus enabling extended collaboration with partners and clients.

Other compatible solutions:

CAD Interop also offers other software compatible with Spirit files, particularly for:

- Conversion and simplification between Spirit and other CAD formats via intermediate formats

- Validation and verification of the quality of exchanged models

These tools are part of the global approach to improving CAD interoperability promoted by CAD Interop, aiming to overcome data exchange challenges that occur "at all stages of a product's lifecycle."

Best Practices for Optimizing Spirit Data Exchange

Effective exchange of Spirit data requires the adoption of certain best practices to ensure the integrity and quality of shared models, taking into account the 2.5D nature of the software.

Recommended export strategies from Spirit:

For architectural and BIM projects, prioritize:

- IFC export for BIM data exchange

- DWG/DXF export for collaboration with AutoCAD users

- STL export for physical modeling needs

These approaches take into account the limitations of Spirit as 2.5D software and optimize exchange with other systems.

Validation before Spirit data exchange:

Before any Spirit data exchange, it is essential to:

- Check the quality of the model to detect possible geometric errors

- Test the export in the target format to confirm the preservation of critical data

- Compare the exported model with the original model to identify differences

These validation steps ensure that your partners will receive usable data that meets your expectations.

Adaptation to specific Spirit data exchange needs:

The export must be adapted to the intended use of the model:

- For technical documentation: prioritize DWG/DXF formats

- For BIM collaboration: IFC format with preliminary verification

- For 3D printing: STL export with optimized parameters

- For feasibility studies: STL export for physical model printing

A preliminary analysis of the recipient's needs allows choosing the most appropriate exchange format, while taking into account the limitations of 2.5D.

Specific Challenges and Solutions for Spirit Interoperability

Spirit data interoperability presents specific challenges related to its 2.5D nature that require adapted solutions.

Common interoperability challenges with Spirit:

Spirit users may encounter several obstacles during data exchange:

- Intrinsic limitation related to 2.5D modeling versus complete 3D

- Variable interpretation of IFC data between different BIM platforms

- Inability to exchange with advanced 3D formats like STEP

- Preservation of specific metadata and attributes

These challenges are amplified by the very nature of Spirit as a 2.5D solution in a world where complete 3D systems are widely used.

Effective solutions and workarounds for exchanging Spirit data:

To overcome these challenges, several approaches can be adopted:

- For exchanges with 3D CAD systems:

- Use compatible intermediate formats (like DXF)

- Accept the limitation of exchanges to basic geometric elements

- Consider specialized third-party conversion solutions

- For BIM and IFC issues:

- Stay informed about continuous improvements to Spirit's IFC interface

- Systematically validate exchanged IFC models in target platforms

- Document known limitations for each type of exchange

- For sensitive data protection:

- Use DEXcenter to secure the transmission of Spirit files

- Implement an exchange registry to track data usage

These solutions significantly mitigate common interoperability problems and optimize workflows involving Spirit data, despite the inherent limitations of 2.5D modeling.

How to Integrate Spirit into a Long-Term Archiving Strategy

Long-term archiving of CAD data represents a major challenge for companies whose projects have an extended lifecycle. For Spirit users, adopting an adapted archiving strategy is essential.

Recommended formats for archiving Spirit data:

For effective archiving of Spirit models, prioritize:

- IFC format for BIM projects

- PDF (2D) formats for visual documentation

- A combination of native and DWG/DXF formats for maximum security

This multi-format approach ensures that your Spirit data will remain accessible even after the evolution of CAD systems.

Archive validation:

Archiving is not limited to storage; it also requires rigorous validation:

- Certify that the archived model faithfully represents the original model

- Regularly check the accessibility of archived data

- Document the conversion processes used for archiving

These validation practices are essential to ensure the reliability of archives and their future usability.

Frequently Asked Questions about Spirit Interoperability

What are the main limitations of Spirit in terms of 3D interoperability?

As 2.5D software, Spirit cannot import or export advanced 3D formats like STEP. This fundamental limitation restricts exchanges to simpler formats like DWG/DXF, STL, or IFC, and strongly influences the interoperability strategies to adopt.

How to ensure the best compatibility between Spirit and common CAD systems?

To optimize compatibility, prioritize DWG/DXF export for exchanges with other CAD systems. Systematically test your exports in the target system and document best practices specific to each partner platform, taking into account the limitations of 2.5D.

Is it possible to convert a Spirit model into a complete 3D model?

Converting a Spirit 2.5D model into a complete 3D model presents inherent limitations. Third-party tools can help with this transition, but expect to have to rebuild certain parts of the model.

How to effectively manage BIM projects with Spirit and other software?

For BIM projects, focus on optimizing IFC exchanges, the preferred format for BIM interoperability. Spirit continuously works on improving its IFC interface, but systematic validation of exchanges remains necessary to ensure the preservation of critical information between different platforms.

Spirit data interoperability, though limited by its 2.5D nature, can be significantly improved through a combination of best practices, specialized tools, and adapted exchange formats. The solutions offered by CAD Interop, particularly SimLab Composer, provide powerful options to fully exploit the potential of Spirit models in a multi-CAD environment, while recognizing and compensating for its technical limitations.

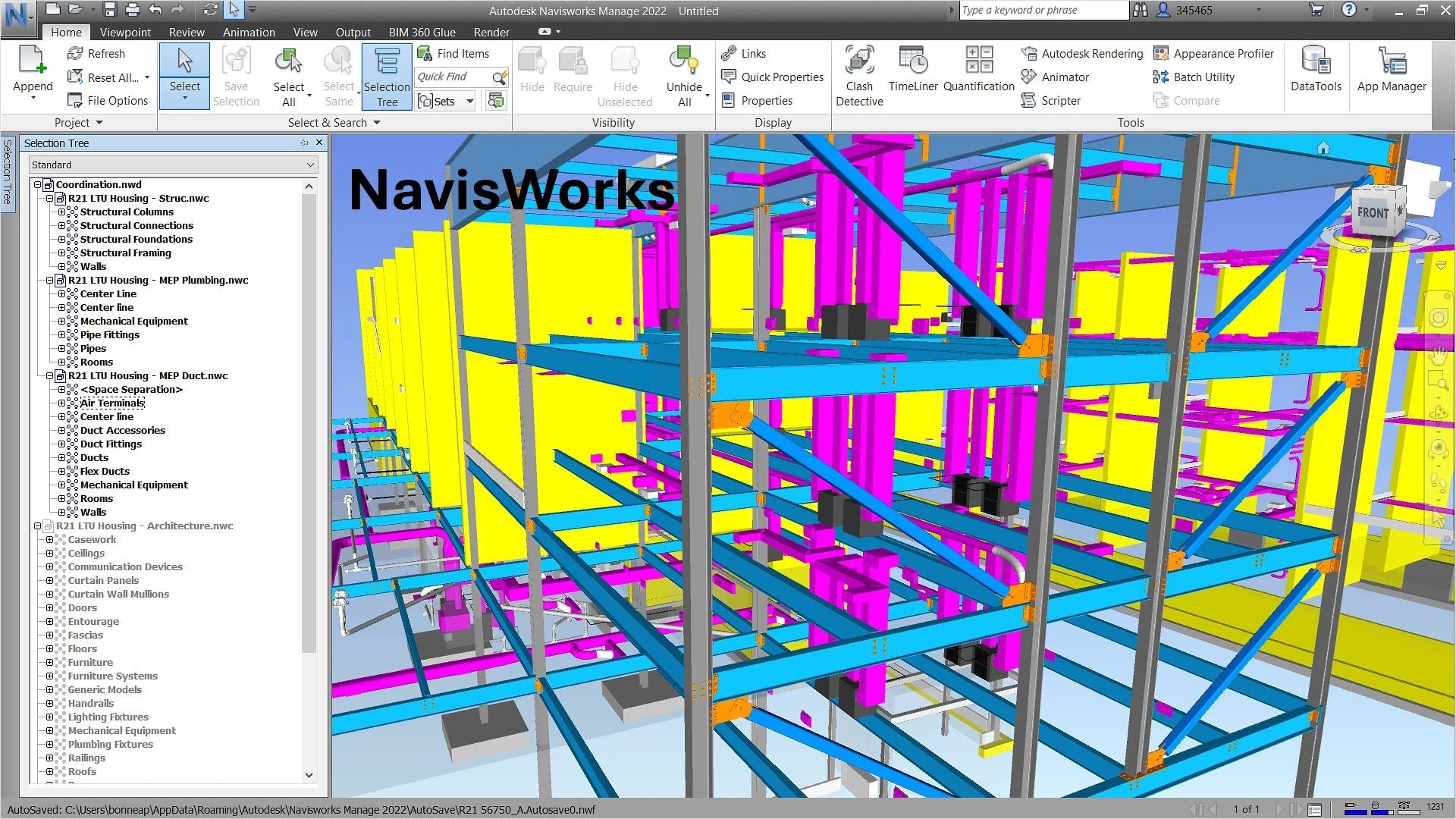

Navisworks is a 3D design review software developed by Autodesk that plays a crucial role in the CAD interoperability ecosystem. As a coordination and project review tool, it allows combining 3D models from various sources and formats to create a complete and coherent project model. Let's discover in detail how Navisworks facilitates CAD data exchange and optimizes collaborative workflows in construction projects.

History and uses of Navisworks software

Acquired by Autodesk, Navisworks has established itself as one of the most reliable review and coordination tools used by construction project managers and VDC (Virtual Design and Construction) professionals. Its development was guided by the need to create a common platform where different models designed on various platforms can be analyzed and coordinated.

Main uses and benefits

Navisworks is primarily used for:

- Detecting and resolving conflicts between different disciplines (structure, MEP, architecture)

- Coordinating complex projects

- Construction simulation and planning (4D)

- Project visualization for client presentations

- Estimation and quantification for quotes (5D)

The software offers considerable advantages in terms of collaboration, including:

- Early detection of conflicts before construction

- Complete project visualization

- Temporal simulation of the construction process

- Accurate project estimation

- Improved risk management

- Streamlined communication between stakeholders

The Navisworks geometric engine

The Navisworks geometric engine is specially designed to optimize rendering and spatial analysis of complex models. It uses simple tessellated geometry that enhances performance when handling large models.

Structure of the geometric engine

Navisworks employs a spatial graph for all spatially oriented operations such as rendering, selection, collision detection, and clash detection. The leaves are self-contained instances comprising a bounding box, transformation, material, and geometry definition, all stored in a format optimized for rendering.

To efficiently support spatial queries, Navisworks uses a hierarchy of spatial bounding boxes (a variant of R-tree). This structure allows the software to quickly process large and complex models.

Data organization

The Navisworks data model is written in separate streams, in the order they are typically read:

- The logical scene graph

- The spatial hierarchy

- The set of instances

- Separate streams for each functionality with its own metadata (clash tests, saved viewpoints, selection sets, etc.)

This organization not only allows loading data on demand but also adding new functionalities without having to modify the file format, thus ensuring compatibility with previous versions.

Navisworks native file formats

Navisworks uses three native file formats, each with specific characteristics and uses:

NWD Format

An NWD file contains all model geometry along with Navisworks-specific data, such as review annotations. This format can be considered as a snapshot of the current state of the model. NWD files are very lightweight, compressing CAD data up to 80% of their original size.

NWF Format

An NWF file contains links to the original native files (listed in the selection tree) along with Navisworks-specific data. No model geometry is saved with this format, which makes an NWF file considerably smaller than an NWD.

NWC Format (cache files)

By default, when you open or append native CAD files or laser scans in Navisworks, a cache file is created in the same directory and with the same name as the original file, but with the .nwc extension. These files are smaller than the original files and speed up access to frequently used files.

Supported CAD and laser scan formats

Navisworks supports a wide range of CAD and laser scan file formats, making it an extremely versatile tool for data interoperability.

CAD formats supported in NavisWorks 2025

Navisworks can open many native CAD formats without requiring the corresponding CAD applications to be installed on your machine:

- CATIA V4: .model, .session, .exp, .dlv3

- CATIA V5: .CATPart, .CATProduct, .cgr

- CIS/2: .stp

- DWF: .dwf, .dwfx, .w2d

- DWG/DXF: .dwg, .dxf

- FBX: .fbx

- IFC: .ifc

- IGES: .igs, .iges, .ige

- Inventor: .ipt, .iam, .ipj

- JT: .jt

- MicroStation Design: .dgn, .prp, .prw

- NX: .prt

- OBJ: .obj

- Parasolid: .x_b, .x_t, .xmt_txt

- PDF: .pdf

- PDS: .dri

- Pro/ENGINEER: .prt, .asm, .g, .neu

- Revit: .rvt, .rfa, .rte

- Rhino: .3dm

- RVM: .rvm

- SAT: .sat, .sab, .smt, .smb

- SketchUp: .skp

- SmartPlant 3D: .vue

- SolidWorks: .prt, .sldprt, .asm, .sldasm

- STEP: .stp, .step, .stpz, .ste

- STL: .stl, .stla, .stlb

- 3D Studio: .3ds, .prj

Laser scan formats supported in Navisworks 2025

Navisworks can also open various laser scan file formats:

- ASCII Laser File: .asc, .txt

- Leica: .pts, .ptx

- ReCap: .rcs, .rcp

Navisworks versions and types

Autodesk offers three distinct versions of Navisworks, each tailored to specific needs in the design and construction industry:

- Navisworks Freedom (beginner level): This is the simplest and free version of the software, often called the Navisworks "viewer." It allows viewing Navisworks files in .NWD and .DWF formats. Although it lacks the advanced features of paid versions, it offers valuable functionality that allows stakeholders to navigate and examine the model without modifying it.

- Navisworks Simulate (intermediate level): This intermediate version offers more advanced features than Freedom, particularly allowing 4D simulations by integrating construction schedules with 3D models.

- Navisworks Manage (advanced level): This is the most comprehensive version, designed to offer complete project review solutions to design and construction professionals. It provides advanced tools for 5D analysis, interference analysis, and spatial coordination.

Plugins and extensions for Navisworks

Navisworks' open architecture allows the use of numerous plugins developed by Autodesk and third parties to extend its functionality. These plugins can be installed automatically or manually depending on their type.

Popular paid plugins

- Navistools Quantification: An advanced plugin that provides powerful tools for surveying and extracting quantities from Navisworks models, crucial for accurate estimation of materials and costs.

- Advanced Work Packaging (AWP): This plugin helps streamline project delivery by breaking down complex tasks into smaller, manageable work packages, particularly useful in large construction projects.

Essential free plugins

- Asite 3D Repo: Enhances collaboration by allowing users to directly connect their Navisworks models to the 3D Repo cloud platform, enabling teams to review and manage 3D models in real-time.

- Coordination Add-in for Navisworks: Essential for teams working on complex projects, it allows easy detection and resolution of conflicts, ensuring that different project elements work together harmoniously.

- Navisworks Plugin for Revit: Ensures smooth transfer of models between Revit and Navisworks, allowing users to import Revit models into Navisworks for detailed review and analysis.

- Navisworks VR Plugin: Allows users to experience 3D models in a fully immersive environment, helping clients and stakeholders better understand the project.

- Enscape for Navisworks: Brings high-quality real-time rendering to your BIM workflow, allowing instantaneous visualization of changes, ideal for project presentations or meetings with clients.

Integration with Autodesk Construction Cloud

Navisworks integrates seamlessly with Autodesk Construction Cloud, offering additional capabilities for BIM management and collaboration. This integration allows for better management of construction data throughout the project lifecycle, ensuring smooth communication between all stakeholders.

CAD Interop solutions for Navisworks

CAD Interop distributes several software solutions to visualize and convert Navisworks files, thus enhancing interoperability and collaboration in your projects.

3DViewStation for visualizing and analyzing Navisworks models

3DViewStation is a powerful solution for visualization, analysis, and conversion of CAD data, including Navisworks models. Its advanced features allow users to:

- Quickly visualize complex 3D models

- Perform precise measurements

- Analyze geometries to detect potential problems

- Create sections and exploded views

- Export to various formats for seamless collaboration

Thanks to its intuitive interface and optimized performance, 3DViewStation is an ideal complement to Navisworks for teams that need to efficiently analyze and share CAD models.

SimLab for creating immersive experiences from Navisworks models

SimLab allows transforming your Navisworks models into immersive virtual reality experiences, offering new perspectives for project presentation and analysis. With SimLab, you can:

- Directly convert Navisworks models into VR environments

- Organize interactive virtual tours

- Simulate real usage scenarios

- Facilitate decision-making through immersive visualization

- Improve communication with clients and stakeholders

This solution adds an extra dimension to your Navisworks projects, allowing a more intuitive and in-depth understanding of designs.

Best practices for exchanging Navisworks models

To maximize the efficiency and reliability of data exchanges with Navisworks, here are some recommendations:

Preparing models for exchange

- Use NWC files to speed up loading times during repeated uses

- Organize your model into logical subsets to facilitate navigation

- Clean up non-essential data before exporting to reduce file sizes

- Check the quality and integrity of models before combining them in Navisworks

Performance optimization

- Use appropriate Level of Detail (LOD) techniques according to project needs

- Leverage Navisworks' caching capabilities for frequently used files

- Divide large models into manageable subsets to improve performance

- Use NWD files for sharing with external partners (contains all necessary data)

Collaboration and coordination

- Establish clear protocols for file naming

- Define common reference points for all models to be combined

- Use DEXcenter to automate and secure CAD data exchanges with partners

- Document the standards and conventions used in the project

Data security

- Take advantage of the secure web environment of solutions like DEXcenter for secure transmission of sensitive proprietary CAD data

- Use data encryption during transfer over the Internet to prevent interception

- Maintain a record of each exchange to validate what was sent to each partner and when