CADIQ identifies problems and differences in CAD models that can impact downstream applications such as analysis and manufacturing. CADIQ's advanced comparison capability allows users to accurately compare 3D CAD models - validating CAD data exchange, migration and legacy data re-mastering processes, as well as facilitating automatic, documented change control and validation as part of a certified data delivery process.

How does CADIQ work?

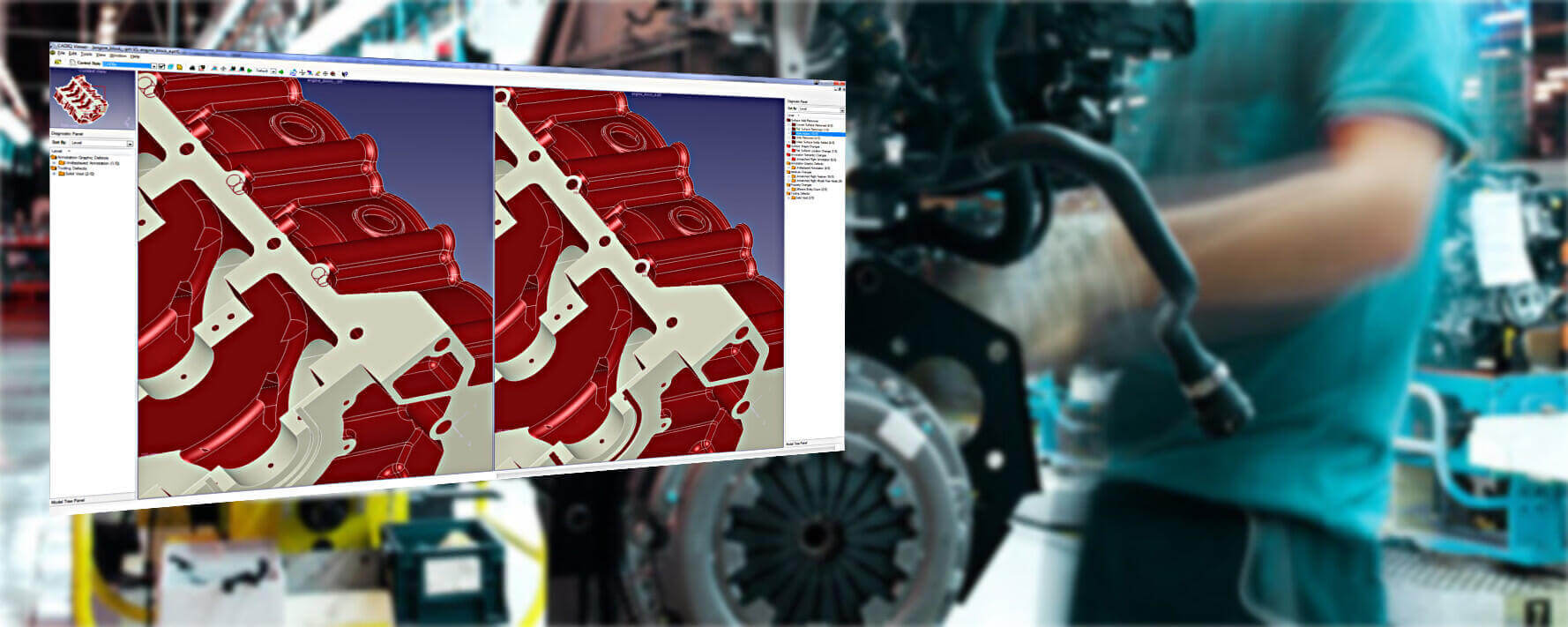

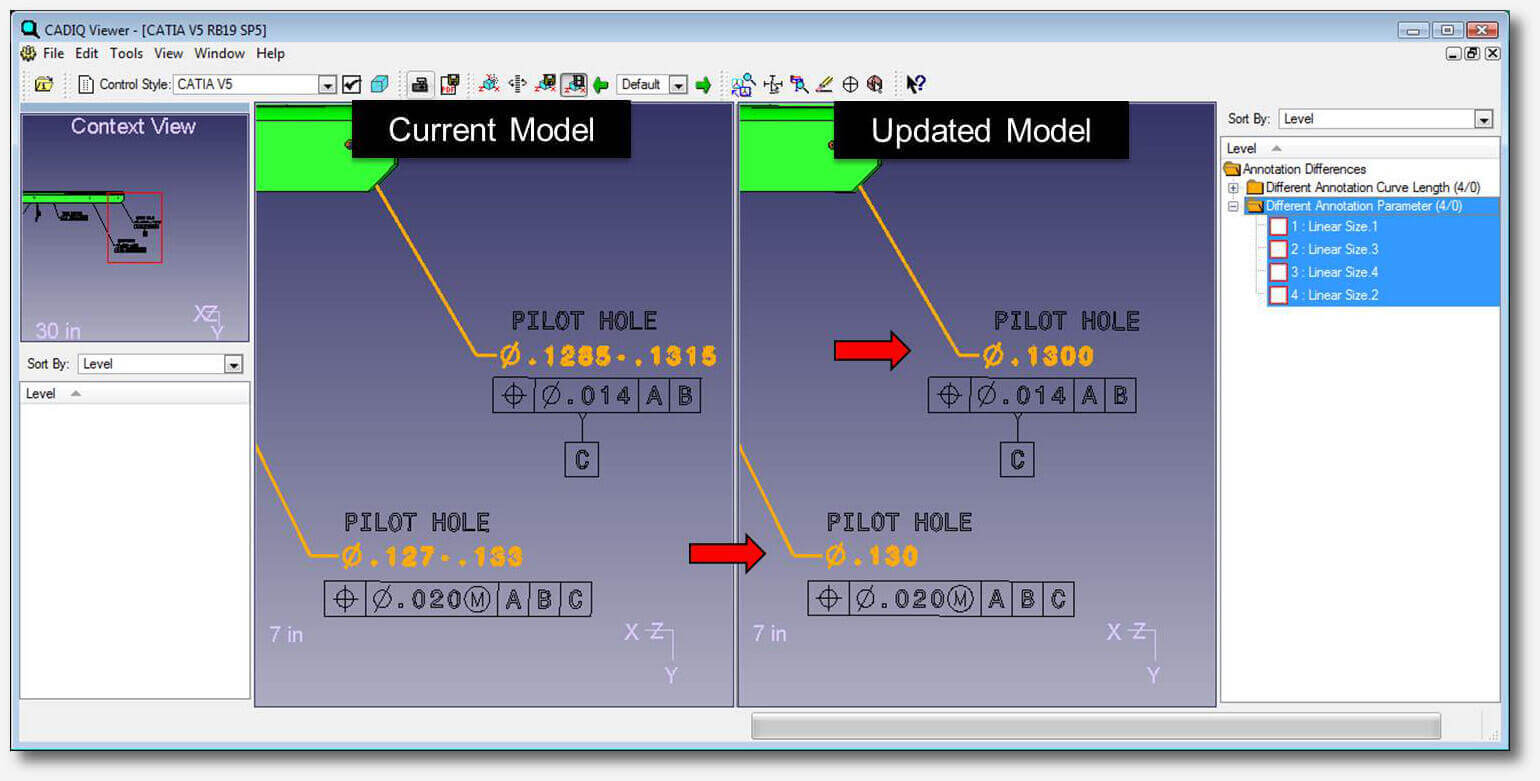

CADIQ validates part and assembly models from all major CAD systems and neutral formats. It identifies problems in an interactive, side-by-side 3D display environment and highlights geometry, features and product structure that has been added, omitted or modified. It identifies changes that can greatly affect reuse in downstream applications such as analysis, manufacturing and data archival. All differences are quickly highlighted with the help of graphic region and mouse controls that can be configured to mimic the user interface of most major CAD systems and thus provide quick productivity to users.

CADIQ Native System Interface Validation

The purest application of product data validation requires an installation of the CAD system because native CAD system programming interfaces are used to analyze the model data "in place" without conversion of the underlying CAD part or assembly. The CADIQ Analyzer can be launched from within an active CAD system session or in standalone mode as managed by the CADIQ Controller. The analysis process can either run locally or on a distributed network of workstations. It has a command line interface to enable integration into an automated workflow or PLM process. The CADIQ Analyzer is available for most major CAD systems on UNIX or Windows.

Native File Interfaces

While CADIQ has always promoted Native System Interfaces as the most robust approach for validation, not all scenarios allow access to native CAD systems. This is especially the case with smaller suppliers that must adhere to typical OEM partner mandates or quality specifications. These procedures often specify that converted forms oforiginal CAD Master Models be properly validated to confirm that the original product design intent was not altered. To support these evolving scenarios, ITI TranscenDataannounces support for Native File Interfaces. This enables the CADIQ Analyzer to work with a mixture of either Native System Interfaces or Native File Interfaces. Thevalidation and business requirements can now drive the type of solution that makes the most sense for customers. CADIQ can also be more simply packaged for customersthat need to quickly validate and document standalone Native CAD files without needing the original CAD system.

Validation results as you need them

There are an assortment of ways to exploit the knowledge from a CADIQ centric validation process.

The validation results can be summarized in Excel spreadsheet with charts, text reports, internal company data formats or integrated directly within your PLM or Six Sigma system. The diagnostic graphics are captured for visualization in the CADIQ Viewer from which annotated side-by-side view differences can be saved into graphic image files.

Diagnostic results can also be marked up and stored as a series of custom views which contain the stored diagnostics, CAD model viewpoints, user notes and user configurations. These custom views are stored within the CADIQ file and can optionally be published to the CADIQ Adobe 3D PDF Report to allow non-CADIQ users access to important validation knowledge.

Who should use CADIQ?

Any organization that designs or manufactures complex discrete mechanical products using 3D CAD models can benefit. CADIQ is especially valuable when data is moved between internal/external analysis and manufacturing systems or between different organizations. A robust validation process assures that quality issues and unknown changes are not propagated. This will allow customer to better control design, manufacturing and product release schedules and costs.